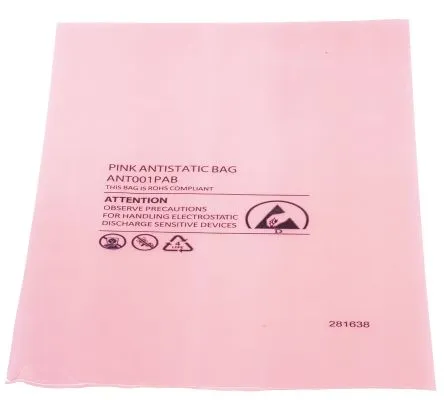

ESD Safe Anti-Static Cubic Bag in Pink/Blue Color for Sensitive Electronic Devices

| US$0.322 | 2,000 Square Meters (MOQ) |

Basic Info.

Standard

RoHS, Reach, MSDS

MOQ

2000m2

Leadtime

10-15 Days

Applications

Electronic Components

Application

Chemical, Industrial, Household

Feature

Recyclable, Moisture Proof

Material

PE

Shape

Plastic Bags

Making Process

Plastic Packaging Bags

Raw Materials

Low Pressure Polyethylene Plastic Bag

Bag Variety

Flat Bag, Ziplock Bag, Organ Bag, Upright Bag, etc

Transport Package

Cartons and Pallets

Specification

Customized

Trademark

Customized

Origin

China

HS Code

3923210000

Production Capacity

20000m2/Day

Packaging & Delivery

Package Size

45.00cm * 30.00cm * 20.00cm

Package Gross Weight

25.000kg

Product Description

Product DescriptionWhat is Electrostatic Discharge? Electrostatic discharge (ESD) occurs when two electrically charged objects like the human body and an electronic device come into contact with each other. Electrostatic discharge can damage or even destroy sensitive electronic parts, alter magnetic media, or set off explosions in highly flammable environments.

If you are storing items that can be damaged by ESD, you need adequate ESD packaging to protect your sensitive components both inside and outside the bag.

An ESD shielding bag is used by the engineering industry and high-end tech companies for storage and protection of PCBs, computer components, motherboards, integrated circuits, and other sensitive parts vital for the business.

You can find ESD bags with different properties, ranging from metalized moisture vapor barrier (MVB) to anti-static pink polyester bags. Ideally, both anti-static and ESD-safe bags for your industry should meet the following requirements:

ESD shielding efficiency Permanent anti-static properties Humidity-independent performance Elimination of corrosion and contamination Heat-stability Transparency. Anti-Static Bags If your industry produces printed circuit boards (PCBs), you need ESD-safe bags to ensure their secure storage and transportation. PCBs are critical parts of pacemakers and electronic games, and since they are prone to damage due to electrostatic discharge, it is essential to store them in adequate packages that won't allow any interference that could damage them.

ESD bags, also known as static shield bags, are suitable for protecting sensitive electronic equipment from electrostatic discharge during storage and transport. Thanks to the 4-layered packaging construction, the items inside the bag will be safe from charges both inside and outside. The inner layer consists of static dissipative polyethylene, and it is surrounded by aluminum shielding. The mid-layer features polyester, while an outer layer is made of static dissipative coating.

Anti-Static Bags Anti-static bags are often coated with an anti-static agent that mitigates the risk of a static imbalance that could affect the electronic component. While anti-static bags prevent triboelectric charge buildup due to the interference with hair, fabric, plastic packaging, etc., they cannot shield items inside the bag from ESD.

Keep in mind that ESD-sensitive tools, including electronic devices and IC components, are not safe from electrostatic discharge when handled or transported outside an ESD-safe area, even when they are inside an anti-static bag.

Remember that blue or pink anti-static bags are ESD safe only for items inside ESD-protected areas (EPA). Only a static shield bag can fully protect the items inside and outside the packaging during transportation or shipping outside an ESD safe space. That said, don't use blue or pink anti-static bags for shipping ESD-sensitive products.

Detailed Photos

Product Parameters

Material : LDPEThickness : 0.03 mm - 0.2mmDimensions: Per customer requestPrinting: Per customer request

Packaging & Shipping

Workshop Display

R&D Strength-Lab equipments

Benefits

Large Selection for Immediate Shipment Options for Custom Bags Low Cost Inert, translucent and do not create a static charge UV Resistant to project from photodegradation of your product Protect products from dirt, dust and other foreign, organic elements Flexible, formable and soft Applications

Food, clothes, lego parts, computer components, pallet cover and various molded laboratory equipments: Q&A

What other types of Polyethylene Bags are available?

Poly bags on rolls / flat bags on rolls

Sheets on rolls / pallet top polyethylene sheeting

Pallet covers

How do I decide what mil thickness is right for my polyethylene bag?

Lightweight 1 or 1.25 mil Great for economical packaging and coverage of lightweight products.

1.5 or 2 mil These are the most commonly used thickness for storing, shipping, or displaying everyday items.

Heavyduty 3 or 4 mil These bags are capable of protecting and supporting heavy and abrasive items.

6 mil These are the toughest bags, offering total protection for the heaviest products.

How do I inspect my bags?

Our polyethylene bags are manufactured under the most controlled tolerances. When inspecting bags remember that polyethylene is very flexible and the gauge can only be measured accurately with a poly micrometer. Machine micrometers, intended for less delicate materials, pinch and flatten bags or film.

Related products

>> Metal Corten Steel Garden Furniture with Fire Pit/BBQ/Camping Metal Wood Stove Burning Heater

>> High quality three-way catalyst converter catalytic converter Ternary catalysis for CHEVROLET EQUINOX

>> aluminum expanded metal mesh panels expanded metal mesh sheet

>> Top Sale 3.8/8t Hay Forage Chopper Chaff Cutter Machine with Diesel Engine

>> BEXKOM Factory Direct Sales Free Design for Cable Assembly

>> Mini Corn Harvester Single Row 400-700mm Corn Combine Harvester

>> CE Horizontal Nanan, Fujian Automatic Twin Spindle CNC Drilling Tapping Machine Hot Sale

>> PVC Powder Color Mixing Equipment Injection Molding Auxiliary Device Blending Machine Heating Cooling Stirring Mixer Unit

>> Double Heads Four Scales Automatic High Accuracy Weighing Cotton Filling Machine (M2-4)

>> 2x2.1m Waterproof Pocket Beach Blanket Folding Camping Mat Mattress Portable Lightweight Outdoor Picnic Sand Beach Mat

>> Water Proof Anti UV Decorative Wall Panel for Outdoor Room Building Storing House Landscape Garden

>> Kraft Cooling Pad Paper Product Type Making Machine Suppliers Hot Sales

>> X7130 China Universal Small Bed Type Milling Machine

>> Perfectrail Car Accessories Auto Body Kit Spare Parts for Changan Uni-K Uni-T Benben E-Star Hunter CS15 CS35 CS55 CS75 Alsvin

>> New Arrival 1111 Model Hand Push Agriculture Portable Gasoline Engine Knapsack Power Sprayer

>> arch top decorative rustic double wrought iron front entry doors

>> TK5490 Timing Chain Kit Auto Engine Spare Parts for Chevrolet 1.5 L Engine No. L2B/B15D2 OE No. 25187737 9025257

>> Raspberry Pi Pi22156 15.6 Inch LCD Capacitive Touchscreen Tablet PC

>> Corn Silage Harvester Combine Crawler Silage Harvesting Machine Silage Harvester

>> Deluxe Pure Steel Smith Cage Gym System for Weight Training

>> Custom Logo Double Side Souvenir Tassel Knitting Soccer Sports Scarf Fashion Women Scarf Wholesale

>> Non slip Dimple Plate Industrial Galvanized Perforated Walkway Grating

>> Industrial Peanut Processing Frying Deoiling Dewatering Machine

>> Chipset 5.0 Clear Sound Quality Motorcycle Helmet Blue Tooth Intercom Headset for CVC Noise Reduction

>> GZ16 Calibration Anvil Steel Anvil for Concrete testing hammer

>> Men′s blue Stripe Comb Cotton Ankle Dress Socks

>> Automatic Process Equipment Vmc1160 CNC Control System Machining Center Safety Protection

>> Automatic foam crusher machine / EPS foam molding machine / EPS foam recycling machine such as eva or epe foaming machine

>> 1 3 gallon 3L 5L plastic bottle blow molding machine blowing moulding machinery

>> Commercial Automatic Bratwurst Stringer Electromechanical Dynamic High-Efficiency Knotting and Winding Machine