Durable Grain Wax Forming Machine with Enhanced Production Features

| US$50,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

pfm3

Type

Pressing Granulator

Object

Petroleum Resin, Phenolic Resin, Sulfur

Material

Carbon Steel/Stainless Steel

Size

Small

Certification

GS, CE, ISO 9001

Condition

New

Weight

5000kg

Delivery Cycle

5 Weeks

Usage

Candle Molding, Waterproof Building Materials, Che

Heating System

Yes

Cooling System

Yes

Forming System

Yes

Cutting System

Yes

Transport Package

Wooden Package

Specification

10 square meters

Trademark

Support customization

Origin

China Hebei

HS Code

8477800090

Production Capacity

200 Sets Per Month

Product Description

Product DescriptionIntroducing the revolutionary automatic control system of our large hydraulic paraffin pellet wax forming machine, complete with an innovative feed system. This advanced machinery ensures precision and efficiency in the wax forming process, setting a new standard in the industry.

The grain wax molding machine is a cutting-edge device meticulously engineered to transform grain wax into a variety of specific shapes, enhancing its properties for optimal use. Perfectly tailored to meet diverse industry needs, this machine stands out as a pinnacle of innovation in wax processing technology.

Major Component Overview

Feeding System: Our sophisticated feeding system, typically featuring a state-of-the-art hopper and a reliable conveying device, is designed to efficiently store and transport the grain wax for processing. The capacity of the hopper varies with the machine's production scale—ranging from holding dozens of kilograms in smaller systems to several tons in larger ones, ensuring seamless operations.

Forming System: The forming system is equipped with versatile rolling devices featuring multiple screens or molds, each with unique apertures and shapes. This flexibility allows the creation of block, plate, and other uniquely shaped granular wax products, catering to the bespoke needs of various industries with precision and creativity.

Heating and Cooling System: Our advanced heating and cooling system employs both resistance and steam heating methods, ensuring optimal processing conditions. The water cooling mechanism efficiently channels cooling water through pipes or jackets, rapidly dissipating heat to maintain the desired cooling speed, thereby safeguarding product quality.

Control System: Equipped with state-of-the-art control systems, our modern wax molding machines guarantee stable operations and precise production management. These advanced systems ensure consistent performance and high-quality output, positioning our machines as leaders in the industry.

Product Parameters

| specification | Minor | 1000mm×600mm×1200mm |

| middle | 2000mm×1000mm×1800mm | |

| large | 5000mm×2000mm×3000mm | |

| weight | Minor | 200-500kg |

| middle | 1-3t | |

| large | >10t | |

| Dynamic system | Motor power | 1.5kw-30kw |

| Rotational speed | 1400r/min 2800r/min | |

| Transmission mode | Belt/gear/chain drive | |

| Heating system | Minor | 3-8kw |

| middle | 10-20kw | |

| large | 30-60kw | |

| temperature | 50 degrees Celsius -150 degrees Celsius | |

| Cooling system | Motor power | 0.3-3kw |

| Air cooling system | 5-10min | |

| Water cooling system | 2-8min | |

| Productive capacity | Minor | 10-50kg/h |

| middle | 100-500kg/h | |

| large | 1000kg/h | |

| Particle size | 1-10mm | |

Dongguang Tiancheng Machinery Factory is strategically located in the Chengnan Development Zone, Dongguang County, Cangzhou City, Hebei Province. Conveniently situated just 50 meters from National Highway 105 and 3 kilometers from the Beijing-Taiwan Highway, our location ensures ease of access.

With a sprawling area of 20 acres and a construction expanse of 5000 square meters, our factory boasts excellent cold and hot processing capabilities. We house 30 sets of precision processing equipment, enabling a wide range of machining capabilities. Supported by a skilled workforce of over 40 employees, including 6 engineering and technical experts, our advanced production equipment and comprehensive testing facilities have earned us a stellar reputation in the petrochemical machinery sector.

Our flagship products include an extensive array of benzol dewaxing refining equipment and technology, including casing crystallizers, plate wax forming machines, particle forming machines, tower granulators, scraper forming machines, and rotary condensing granulators. With numerous national patents, our products are in high demand both domestically and internationally, serving a multitude of major petrochemical enterprises.

At Dongguang Tiancheng Machinery Factory, we steadfastly uphold our business ethos of 'customer first, quality first, reputation first, service first.' We are committed to pursuing excellence, achieving remarkable outcomes, and warmly welcome both new and returning customers to engage with us for guidance and collaboration.

Main Product

Certifications

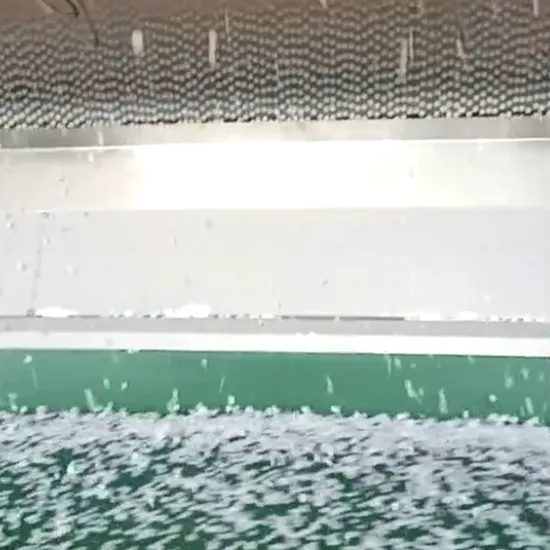

Product Display

Packaging & Shipping

>> Bakery Round Bread Bun Pizza Dough Divider Rounder Automatic Dough Rounder and Divider Cutter Ball Rounding Making Machine Maker

>> High Quality Electrical Laying Tool Manhole Cable Pulley, Three Drum Cable Roller, Straight Line Single Cable Pulling Roller

>> Outdoor Extra Large Post Box Metal Storage Parcel Drop Box For Mail And Parcel

>> Food Tray Good Quality Paper Box Making Machine

>> YY jindal aluminium section sliding window with double glazed for home use

>> stainless steel 304 stamping drip tray metal stream bottle soda bottle rack

>> Baby 1-3 Years Old Music Hand Push Baby Walker Anti-Rollover Speed Regulating Multi-Function Walker Toy

>> Fake Down Fiber Cotton Polyster Filling Stuffing Machine Heyi Factory

>> Dental High and Low Speed Air Turbine Handpiece Kits 2PCS Pana Max1 Push Button Handpiece+203c Low Speed Sets Blue

>> Raw Material Processing Equipment Mechanical Rubber Rolling Series

>> Ricoh Digital Printer 7100 Printer Photocopier

>> Qf11 Wholesale Power Bank with Built-in Cables Portable Fast Charging Power Bank

>> Automatic Small Processing Plant Tomato Paste Production Line Tomato Juice Powder Processing Machine Tomato Sauce Ketchup Making Machine

>> 6 Cylinder 4 Stroke 957kw Zichai Zc6270 Series Marine Diesel Engine (ZC6270ZLC-10)

>> Lab Textile Dyeing Machine for Laboratory Automatic Dripping Machine

>> Weijia Construction high quality aluminum casement window factory glass window aluminum window

>> Quality Model Computer Keyboard Industrial Silicone Keyboard Onikuma

>> Swj-16b High Speed Vertical Tapping Machine Metal Heavy Duty Cast Iron Steel Tapper Machine M16 M12

>> New Arrival Vintage Retro Luxury One-Piece Sun Glasses Square Frame Oversized Men/Women Sunglasses

>> Passenger Car Wheels Tires 175 70r13 195 R15 205 65 R16 225 55 16 205 60 16

>> Sample Customization Scented Soy Aromatherapy Candle Highly Scented and Cute Elegant Ceramic Jar Candle 4.2 Oz, Candle Gift for Women Home Scented

>> Full Automatic 3000L/H Fresh Juice Production Line

>> Xn Aluminum Light Steel Keel Drywall Omega Profile Roll Forming Machine

>> Good Quality Low Price Horizontal Drilling & Tapping Machine Driller Vertical

>> Double Z Type Blades Sigma Mixer Rubber Kneader with Electric Heating

>> Aluminum Manufacturing Specialist Providing Fast Prototyping and CNC Services

>> 100 Tons Automatic Rice Milling Machine Complete Set Commercial Rice Mill Machine

>> Spz-3r Small Dry Mixin Construction Shotcrete Machine

>> Wholesale Stainless steel BBQ Net Flattened expanded metal mesh for outdoor BBQ

>> Disposable Isolation Gown PP Protective Gown Non-woven Single-use Protective Apparel from China Factory