Versatile Mushroom Matrix Mixer for Smooth Material Distribution

Basic Info.

Model NO.

XH-BLQ

Application Area

Mushroom Cultivation

Condition

New

Control System

PLC Control

Cooling Method

Air Cooling

Main Material

Carbon Steel

Mixing Capacity

≤10L

Safety Features

Overload Protection

Speed Control

Single Speed

Stirring Type

Spiral

Temperature Control

Without Heating

Working

High Speed Mixer

Power

5.5kw

Weight

2500kg

Dimensions

7600X500X2200mm

No. Workstation

3 Workstations

Supporting Equipment

Full-Automatic Packing Machine

Distance Between Stations

2.3m

Iron Plate Thickness

5mm

Shell Material

Carbon Steel Plate

Transport Package

Wooden Case

Specification

Customized

Trademark

XINGHANG

Origin

China

Packaging & Delivery

Package Size

770.00cm * 60.00cm * 230.00cm

Package Gross Weight

2505.000kg

Product Description

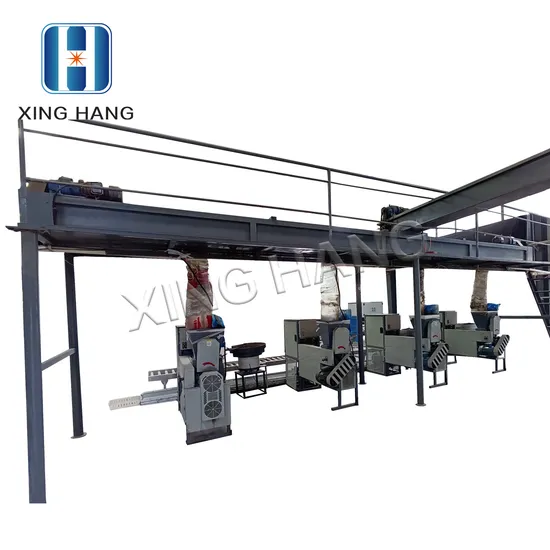

Product Description| MUSHROOM DISTRIBUTOR |

Main features:

1. Efficient and stable: Adopting advanced design to ensure smooth machine operation and high material separation efficiency.

2. Easy to operate: The structural design is reasonable, the operation is simple and fast, and it is convenient for users to use.

3. Customized services: Flexible customization according to user needs to meet different production requirements. Detailed Photos

| STRUCTURE OF MUSHROOM DISTRIBUTOR |

Material box: used to store mushroom materials to be mixed and distributed.

Conveyor device: Use a conveyor belt to transport mushroom material from the bin to the mixing position.

Discharge outlet: The mushroom material is fed into the bagging machine through the discharge port.

Mixing device: thoroughly mix the mushroom material before distribution.

Control device: equipped with automatic control function to achieve more precise operation.

Product Parameters

| Number of stations | Specifications | Dimensions of groove | Height above ground | Motor Power | Weight | Dimensions |

| 3 Work stations | 1500mm | 690x450mm | 1700mm | 4KW | 1715kg | 6000x450x1700mm |

| 2500mm | 880x500mm | 2200mm | 5.5KW | 2500kg | 7600x500x2200mm | |

| 4 Work stations | 1500mm | 690x450mm | 1700mm | 4KW dual motor | 2065kg | 7500x450x1700mm |

| 2500mm | 880x500mm | 2200mm | 7.5KW dual motor | 2950kg | 9900x500x2200mm | |

| 5 Work stations | 1500mm | 880x500mm | 1700mm | 5.5KW dual motor | 2635kg | 9000x500x1700mm |

| 2500mm | 880x500mm | 2200mm | 7.5KW dual motor | 3428kg | 12200x500x2200mm | |

| 6 Work stations | 1500mm | 880x500mm | 1700mm | 5.5KW dual motor | 3715kg | 10500x500x1700mm |

| 2500mm | 880x500mm | 2200mm | 11KW dual motor | 3890kg | 14500x500x2200mm | |

| 7 Work stations | 1500mm | 880x500mm | 1700mm | 7.5KW dual motor | 4065kg | 12000x500x1700mm |

| 8 Work stations | 1500mm | 880x500mm | 1700mm | 11KW dual motor | 4614kg | 13500x500x1700mm |

| ADVANTAGES |

2.The source manufacturer has no middleman

3.Strict quality inspection rest assured of quality

4.Superior material, safe and reliable wear and tear resistance, long service life Product show

Company Profile

>> Durable AAC Equipment Block Making Machine for High-Volume Production Needs

>> Zc-400 Glue Back Notebook Spine Binding Machine

>> Pure Silent Absorption Air Cooler Fridge Luxury Foam Door with Lock

>> 220m/360m/460m/560m Hydraulic Mobile Crawler Truck Mounted Portable Water Well Drilling Machine

>> Cleanroom Panel High Efficiency Fiberglass HEPA Filter Air Filter Manufacturer

>> Combined Screen Display Active HD EMI EDID HDTV 1080P 4K 8K 60Hz 144Hz USB 3.1 C Type Mini Dp to Displayport DVI VGA Adapter for MacBook PC Computer

>> 1000kg/Hr HDPE PP PE Milk Bottles Recycle Sustainability Packaging Recycing Washing Line

>> Factory Apparatus Scuba Snorkel Swimwear Diving Equipment Diving Mask

>> Advanced 3015/4020/6020/6025 OEM/ODM High-Quality CNC Laser Cutter for Plate and Tube with Separate Electric Cabinet

>> Hose Crimping Machine Made in China

>> Nvidia Jetson Orin Nx 16GB Module Pn: 900-13767-0000-000

>> Fiber Cement Board Flow-on Double Width Production Line Equipment Processing Workshop

>> Custom Stainless Steel OEM Screw Pin Shaft CNC Lathe Machining Joint Car Parts

>> Multi Touch 42"-98" Inch Electronic IR Interactive Whiteboard, Smart Board No Projector Interactive Whiteboard

>> Widely Application Multi-Functional Soybean Millet Sorghum Shelling Corn Thresher Maize Sheller

>> China Origin New Crop Fresh Carrot Grade a+ S, M, L Size, 5kg/Carton, 10kg/Carton Top Quality, Lowest Price, China Origin, Big Volume, Good Service

>> OEM ODM wholesale fashion brand Skmei 1872 new arrival 5Bar waterproof PU band men sport digital wristwatch

>> 100W Plywood MDF Leather Acrylic 1390 CO2 Laser Engraving and Cutting Machine

>> Popular Watches Men Wrist Unique Watch Herren UHR Custom Logo Relojes Hombre Water Proof Luxury Watch

>> 22HP Diesel Engine Towable Backhoe

>> Fully Automatic Dog Poop Bag on Roll Making Machine with Core

>> Nail Salon Luxury No Plumbing Foot SPA Pedicure Massage Chair

>> Factory Customizable Fully Auto Plastic Injection Molding Machine

>> Carbon Fiber Motorcycle Spare Parts for Suzuki Gsxr 1000 Fenders Fairings Huggers

>> Jingsun Solar Power Plant 2MW Solar System Tie Grid 2000kw Solar Panels Solution

>> Classic Custom Casual Trucker Baseball Cap Adjustable Size Checked Mesh Sports Caps

>> Flower Drum Bicycle, High-Qualitybicycle Hub Components for

>> Hydraulic Radial Drilling Machine Z3050*16

>> Pigment Grinding Machine Three Roller Mill MOQ 1 Set

>> Series Y High Precision Double Side Grinding Machine for Carbide Cutter Blades