Plastic Single Extruder Double Three Triple Layer PPR PE HDPE LLDPE Irrigation Water Supply Energy Gas Plumb Hose Pipe Tube Production Making Machine

| US$2,000.00-50,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

GF160

Screw No.

Single-screw

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008

Customized

Customized

Condition

New

After-sales Service

One Year for Free

Electrical Components

Siemens, ABB, Omron, FUJI, etc.

Delivery Time

Around 40 Days

Pipe Diameter

From 16mm-1200mm

Motor Brand

Siemens

Extruder Control

by Siemens PLC Screen Touch

Motor Drive/Inverter

ABB Brand

Pipe Usage

Water, Engergy, Gas, Irrigation, etc.

Production Speed

Around 0.5-20meter/Minute

Shipment

LCL and FCL

Machine Installation

Available

Transport Package

Plastic Film and Wooden Box

Specification

Pipe size upto 1200mm

Trademark

CONBOPLAS

Origin

Zhangjiagang

HS Code

84778000

Production Capacity

30 Sets Per Month

Packaging & Delivery

Package Size

1000.00cm * 1000.00cm * 1000.00cm

Package Gross Weight

5000.000kg

Product Description

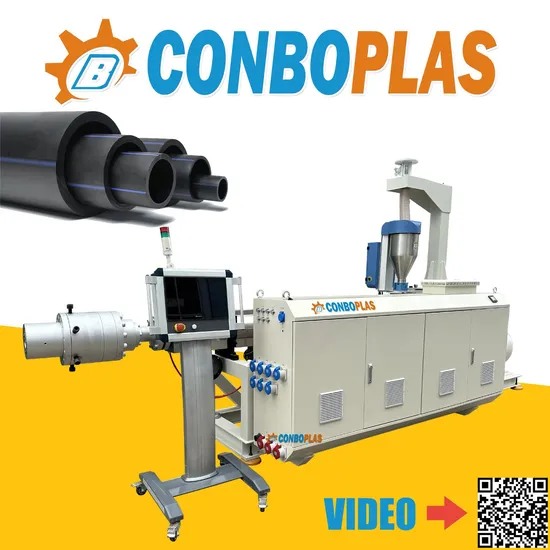

Plastic Single Extruder Double Three Triple Layer PPR PE HDPE LLDPE Irrigation Water Supply Energy Gas plumb Hose Pipe Tube Production Making MachineProduct Description

Plastic Single Extruder Double Three Triple Layer PPR PE HDPE LLDPE LDPE Irrigation Water Supply Energy Gas Hose Pipe Tube Extrusion Production Making Machine.

PE pipe production line is primarily used in the manufacturing of PE pipes with diameters ranging from 16mm to 1200mm. The various thickness of the pipes produced can make them suitable for applications range from urban water supply to gas transportation. This line also excels in the production of anti-flammable and anti-static electricity pipes using a two- or three-layer spiral mold for use in mining industries. Pipes produced feature even wall-thickness and perfect roundness. Through switching or adding certain part of machine unit, this line can also be customized to extrude pipes of various other kinds.

Features

The optimum spiral structure-feeding throat highly improves the output of extruder;

Accurate temperature control system ensures materials melting performance;

Unique screw design achieves better plasticizing and high-quality products;

Precisely designed gearbox with a high torsion guarantees stable running;

"H" shape frame to decrease vibrating of extruder;

Advanced PLC operation system realizes synchronization and automation;

Adopt automatic water temperature & level control and special independent filters on both vacuum and cooling tanks;

Offer stable haul-off unit with 2-12 caterpillars;

Provide saw & chip-free cutting options;

Low energy consumption, excellent performance, and easy maintenance.

Product Parameters

| Item/Model | GF63 | GF110 | GF160 | GF250 | GF315 | GF630 | GF800 |

| Diameter range/mm | 16-63 | 16-110 | 50-160 | 50-250 | 110-315 | 315-630 | 400-800 |

| Claw number of haul off/pcs | 2 | 2 | 2 | 3 | 4 | 6 | 8 |

| Pulling force/KN | 6 | 8 | 11 | 20 | 30 | 40 | 50 |

| Pulling speed/meter/minute | 15 | 12 | 8 | 9 | 4 | 2 | 2 |

Remarks: all information above is only for refererence; please gather the exact data by contacting us.

Detailed Photos

Machining Equipment

Electric Components

Business Cooperation

More Products For Option

PVC PIPE PRODUCTION LINE, WATER PIPE EXTRUDER, DRAINAGE PIPE MAKING MACHINES

PPR HOT COLD WATER PIPE PRODUCTION LINE

DOUBLE OUT PVC CONDUIT PIPE PRODUCTION LINE, PVC WATER PIPE EXTRUDER MACHINES

LARGE PLASTIC PVC HDPE MPP PP PIPE SHREDDER, SINGLE SHAFT SHREDDER

PLASTIC PVC PP PE ABS PC LUMPS SHREDDER, PIPE SHREDDER, SINGLE SHAFT SHREDDER

PLS FEEL FREE TO CONTACT US FOR FURTHER DETAILS. THANKS!

>> Interactive Projection Game Virtual Reality Games Motion Capture Interactive Wall Projection System for Kids

>> Auto Parts OE No. 4n0857535A Side Mirror Glass

>> Wholesale Travel Toiletry Organizer Corduroy Zipper Makeup Cosmetic Bag

>> Sqmg 5.5 7.8cbm Truck Mobile Mixer Self Loading Concrete Cement Mixer Truck Price

>> Automobile Tension Pulley with Idler Bearing

>> Artificial Decorative Plant Fixed in Resin Water Artificial Fern Plant

>> Wholesale quality diamond hole perforated metal mesh for facade cladding and ceiling use

>> Oxygen/Nitrogen Generator Cryogenic Air Separation Plant with Efficient and Stable

>> Best Harvester Machine Corn Wheat Rice Combine Harvesters Mini/Small Combine Harvester Hot Sale

>> Cheap Men Garment Cover Bags No Woven Suit Bag with Zipper Storage Bag

>> Automatic Commercial Puffed Food/Snack/Tortilla/Cornflakes/Rice Crust/Stuffed Rice/Nutrition Powder/French Fries Production Line/Machine

>> Powerline marker 800mm orange aviation obstruction fiberglass warning sphere

>> UAE Poultry Farm Equipment for Sale in Bangladesh/Srilanka

>> Reject Sorter for Paper Mill Paper Recycling Pulp Equipment

>> Stainless Steel Portable Electric and Gasoline Engine Sheep Goat Milking Machine

>> New Huayang Customized Hotel Bed King Size China Wholesale Wooden Furniture

>> Wholesale Custom Waterproof Thermal Xxl Insulated Extra Large Delivery Bags

>> Full Set E Class W212 E63 body kit for W212 Front Bumper Rear Bumper

>> Copper ball mill balls small scale mineral mining silica sand stone wet dry quartz grinding 600x1200 gold ball mill for sale

>> Steel Frame Stud and Track for Gypsum Board Drywall

>> Nc Series Metalworking Steel Plate Double Side Milling Machine

>> bagasse sugarcane briquette making press machine

>> OEM Injection Plastic Dustbin Mould Manufacture in Taizhou

>> Hot Sale Premium Co-Extruded Custom Black Poly Bubble Plastic Mail Bags

>> Kubota Harvester Parts 5t076-16412 Lh Axle for Sale

>> Reliable Cone Crusher for Robust Rock and Stone Processing Solutions

>> 8" Coaxial in Ceiling Speaker

>> 2022 Hot Sale Paper Cup Production Making Machine Price,Coffee paper Cup Making Machine

>> Wholesale hospital pink white dress skirt designs medical scrubs nurse uniform

>> High-Precision Indexable Insert for Steel and Cast Iron Cutting