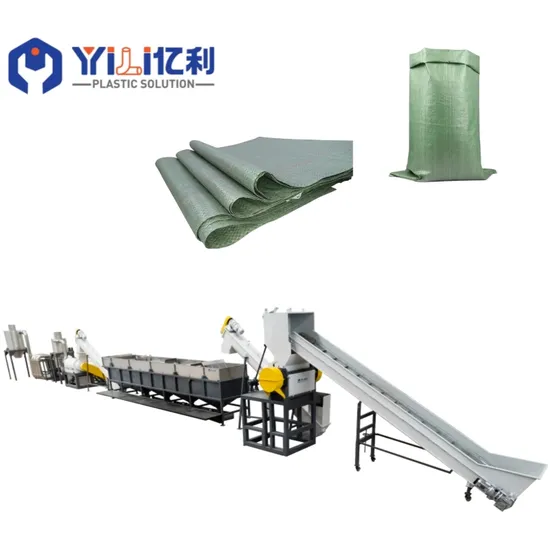

Advanced Plastic Waste Recycling Machine for Woven Bags

| US$40,000.00-90,000.00 | 1 Piece (MOQ) |

Basic Info.

Material Processed

Film

Plastic Type

PE PP PS

Screw

No

Automation

Automation

Computerized

Computerized

Certification

ISO9001:2008, CE

Suitable Material

Post Consumer Film, Agricultural Film, Woven Bag

Output Capacity

150-1000kg/H

Motor Brand

Siemens, Weg

Bearing

NSK

Controller

Siemens PLC or Button Control

Customized

Customized

Material

Stainless Steel SUS304

After-Sale Service

Engineers Available to Service Machinery Overseas

Process

Shredding, Crushing, Washing, Drying

Electric Components

ABB, Ls, Omron, or Customized

Transport Package

Plastic Film and Wooden Pallet

Specification

20m

Trademark

YILI

Origin

Zhangjiagang, China

HS Code

84778000

Production Capacity

30 Sets/Per Year

Packaging & Delivery

Package Size

200.00cm * 160.00cm * 210.00cm

Package Gross Weight

1000.000kg

Product Description

Applicable Material:Our versatile machine caters to a wide range of materials including PE/PP Films, Industrial Films, City garbage film, PP woven bags, and even Raffia jumbo bags.

Introduction

The waste plastic film recycling and comprehensive washing line crafted by YILI Machinery can expertly treat diverse kinds of plastic soft materials, such as PE or PP plastic film, PP woven bags, and an array of waste materials including agricultural films, soft drip irrigation pipes, industrial packing films, and supermarket packing films, to name a few. This sophisticated production line integrates essential components such as a shredder, crusher, frication washer, floating tank, and squeezer, boasting capacities ranging from 300 to an impressive 1500 kg/hr. Our film washing line guarantees meticulous and effective decontamination of waste films using both cold and hot washing systems, incorporating leading-edge recycling technologies. The resultant high-quality products can be utilized standalone or blended with other materials for reprocessing, even suitable for creating new film applications.

Technical Parameters

| Model | Capacity (kg/hr) | Power installed (Kw) | Water consumption (ton/hr) | Manpower |

| QX300 | 300-400 | 160 | 0.5 | 3 |

| QX500 | 500-600 | 200 | 1.2 | 3 |

| QX1000 | 800-1000 | 250 | 3 | 4 |

| QX1500 | 1300-1500 | 325 | 4 | 4 |

| QX2000 | 1800-2000 | 415 | 4 | 4 |

Tech Features & Advantages Our fully automated production line features compact processing, exceptional production efficiency, and impeccable cleanliness; Effortlessly separates mud, sands, and other impurities from films and bags; Equipped with advanced pre-treatment systems like Pre-washer and Label processing, it can significantly enhance the quality of the final product; Incorporates state-of-the-art centrifugal dewatering and squeezing technology; Offers easy maintenance, energy efficiency, and a durable lifespan

Main Machines For the line

Belt conveyor

Choose from light or heavy duty belt conveyors. Features a gearbox motor and side walls to prevent material spillage. Optional installation of metal detectors enhances functionality.

Shredder Our shredder is ideal for processing large raw materials such as plastic drums, tanks, and lumps. It performs preliminary grinding before the material is further processed by a secondary crusher, reducing sizes to less than 12mm for optimal purity. YILI offers a variety of shredders with diverse capacities and capabilities to cater to specific customer needs.

Crusher

Designed to crush materials into smaller, more manageable pieces, our crusher integrates water to clean materials and cool blades during operation. This process enhances washing efficacy and facilitates easy packaging of the final product.

Frication Washer The high-speed frication washer efficiently cleans plastics by removing contaminants, dirt, and grease, preparing the material for further cleaning in the floating tank.

Floating tank

This module effectively separates sediment and metal from materials. It features washing wheels of varied designs for specific functions, all controlled via inverter speed settings. With a magnetic valve at the base, it timely discharges dirt. The tank is constructed from robust stainless steel for longevity.

Centrifugal Dryer Our horizontal centrifugal dryer offers outstanding drying performance while being energy efficient. Its self-washing grid mesh, activated by timer, ensures both washing and drying of plastic flakes.

Hot air pipeline heating

43c71cd8

>> Manufactures 70GSM 75GSM 80GSM A4 Copy Paper Draft Double White Office Paper

>> 228b Blanket Raschel Double Needle Bar Warp Knitting Machine

>> Yolanda Luxury CEO Manager Office Furniture Made in China Executive Desk Office Table Boss Desk Executive Office Desk

>> auto body parts car engine hood bonnet for SUNNY N17 2011

>> Hot sale FOR Chevrolet Equinox Malibu XL Silencer 1.5 T 24111775 24109773 24105349

>> Weiyan Wy-9QS-3 Factory High Capacity 3.8 Ton/H Capacity Chaff Cutter Kneading Grass Chopper Machine with Chain Conveyor Belt

>> China Normal Precision Sumore Wooden Box 50mm Tools Milling Machine

>> Large Capacity Stainless Steel Pressing Type Thermo Flask with Cover

>> Marshell 4 Seater Lithium Battery Operated Golf Cart Golf Buggy (DH-M4+2)

>> Side Mirror Rearview Suit 87910-47120 R For Prius

>> Simple Nordic Style Modern Wall Mount Hanging Brass Gold Coat Rack

>> 1.5mm 2.5mm Flexible PVC Insulated Electric Wire Speaker Signal Audio Cable

>> Nadun Manufacturer Sells Shaft Type Disc Type Vertical CNC Lathes Vtc75

>> Customized OEM Service Inverter 18000BTU Split Klimaanlage

>> Slim Short Women Hoodie crop top hooded shirt

>> Wholesale Modern Simple High Quality Commercial Wood Top Restaurant Table

>> Wood Timber Treatment Plant Wood Preservative Impregnation Autoclave

>> Baby carriage Velvet Jewelry Box stroller Wedding Ring Box Gift Box Holder Case for Earrings Necklaces Bracelets Display

>> China Extruded Polypropylene Board PP Sheets Plate high quality Suppliers

>> Hot Sale Shacman Mixer Truck Meter Concrete Trucks Pumping

>> 102 Aluminium Pin Plate for Lk Stenter Machine (YY-446)

>> New Portable Trade Show Aluminium Backdrop Booth Display Stand

>> Aluminum alloy pressure relief valve for regenerative air blower

>> Yada Renewable And Biodegradable Disposable Eco-friendly Custom Wood Cups Natural Pine Cup Sushi Tray

>> Film Bowling ABA Machine Blowing Film Film Bowling ABA Machine Sja Model Normal HDPE LDPE ABA Film Blowing Machine

>> Professional Complete Suture Practice Kit for Medical Students

>> Ultrasonic Woven Label Cutting Making Machine Multiple-function Plastic Label Sheet Ultrasonic Press Welding Machine

>> Sawdust briquette charcoal making machine charcoal briquette machine

>> Bamboo Grilling Skewers

>> Dolomite Rotary Kiln Production Line for Customized Production Needs