PU Foaming Spray Preinsulation Pipe Continuous machinery

| US$1,000,000.00-1,300,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

preinsulated pipe 508-1620

Type

Polyurethane Foam Machine

Raw Material

HDPE

Principle

High-Pressure Air Type

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008

Application

Hot Chiller Water/Oil /Chemical Material Pipeline

Turnkey Project

Yes

Pipe Structure

Carrier Steel Pipe-Polyurethane Foam-HDPE Casing

Capability

3-4unit/H

Foaming Thickness

30-100mm

Transport Package

Wodden Box

Specification

pipe dia. 508-1620mm

Trademark

Huashida

Origin

Qingdao, China

HS Code

8477209000

Production Capacity

20 Sets/Year

Packaging & Delivery

Package Size

1200.00cm * 230.00cm * 260.00cm

Package Gross Weight

1000.000kg

Product Description

PU Foaming spary Preinsulation Pipe Continuous machineryProduct Description

The polyurethane sprayed polyethylene thermal winding preinsulation pipe production line independently developed by Huashida, consists of three parts: External shot blasting and derusting collector production line, polyurethane spraying production line, and PE winding production line. The line has a number of national patents, and the third-party standardized evaluation report has a technology advanced level of 5, reaching the domestic leading level. And won the first set of technical equipment in Shandong Province.

The line adopts continuous spraying production process. High automatic, fast production efficiency, saving raw materials, increased foaming and closed cell rate, lower water absorption rate, trinity molding, and more reliable performance. Products with low carbon environmental protection have higher economic and social benefits.

PU Foaming spary Preinsulation Pipe Continuous Production Line

Product Parameters

Producing technology flow of the polyurethane coating steel preinsulated pipe equipment:

1. Remove rust from steel pipe surface

2. preheat the steel pipe to get it ready for polyurethane spraying

3. Spray polyurethane evenly on steel pipe outer surface

4. Wrap melted HDPE strap around the PU foam

5. Trim the pipe ends

Main line Composition of the polyurethane coating steel preinsulated pipe equipment:

| No. | name |

| 1 | External wall Shot blasting rust removel machine |

| 2 | Medium-frequency induction heating furnace |

| 3 | Polyurethane spray foaming unit |

| 4 | pipe rotator trolley |

| 5 | Single screw extruder and diehead mould |

| 6 | Finished pipe ends trimming machine |

| 7 | pipe Conveyers and racks |

| 8 | Electrical system and PLC |

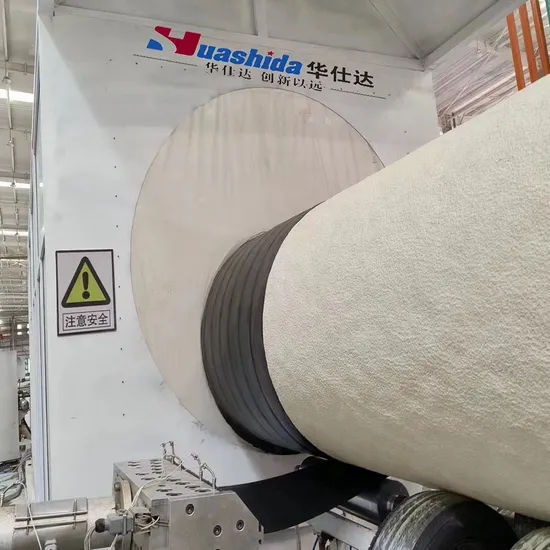

Photos show

PE film jacket wrapping

PE Jacket Water quenching Company Profile

Qingdao Huashida Machinery Co., Ltd was established in 2003. Since its inception, Huashida has focused on plastic polyurethane insulation pipe production line, 3PE anti-corrosion pipe production line, large diameter underground pipe production line and plastic pipe joints for 20 years. We always attach great importance to research and development,

collaborating closely with Beijing University of chemical technology, Qingdao university of technology and scientific research institutions. by absorbing advanced technology home and abroad, after 20 years of endeavor we now rank one of the top 3 manufacturers in the industry in China. Huashida machines have been well received in Saudi Arabia, Kazakhstan, Uzbekistan, United Arab Emirates, Turkey, Russia, etc.

International Trading show

Clients case

Container Delivery Certifications

Thank you very much for you looking into Huashida equipment. For more details, please come back to us. We will respond immediatedly

and work out a customized plan for you according to your requirements and demands.

>> Taijia Hot sell Electric Concrete steel Resistivity measuring Meter Digital Concrete Resistivity Meter

>> CK-102 Digital Crack Width Gauge

>> Jacquard Nylon Spandex for Underwear Fabric

>> Rigid Hard Plastic Recycling Machine Waste Plastic Washing Machine HDPE PP Bottles Washing Line

>> High-Efficiency Aluminium Steel Bars Frames Shearing Machine

>> BM38/12 FINCM CNC High Speed Gantry Surface Milling Machine

>> Runway waterproof plastic mat Sports mat Outdoor kindergarten suspended assembled floor Basketball mat

>> New Tech Commercial Deep Fryer Gas Two Baskets Chicken Chip Friers Donut Catering Equipment Restaurant Machine

>> China Manufacturer Concrete Mixer Machines

>> High Quality Custom Precision CNC Machining Parts

>> Automatically Length-Measuring System for Pipe Cutting (PCMLS-24A)

>> Diamond Concrete Cutting Rope Wire Saw for Construction Use

>> Taijia Rebound Hammer for Concrete strength test civil Engineering Rebound Hammer for Non Destructive Testing of Concrete

>> High Quality Custom Design Circuits Board Aluminum LED PCB Assembly OEM PCB

>> High Quality CAS 28211-04-3 Epsilon-Polylysine From China Supplier

>> Precise Centerless Grinding Machine M1050A Centerless Grinder

>> 360mm Rear Shock Absorber for ATV Quad Dirt Bike 110cc 125cc 150cc

>> Byloo worlds shortest fishing rod and teel high modulus carbon fiber prepreg fishing rod

>> Top Part Terminal Box Y2 Three Phase Electric Motor Cast Iron B5

>> High Quality Plastics Rubber Limiting Oxygen Index tester

>> Xcm G 19m Xg1930DC Xg1932DC Scissor Lift for Sale

>> Low moq massage gun cute dropshipping massagegun supplier

>> Wireless Concrete Crack Depth Gauge Crack Width Camera

>> New 4X2 30m3 Concrete Mixer Truck with Pump 26m Boom for Sale

>> Timing belt tensioner 93744701 for Daewoo Chevrolet Matiz Spark GM 93744701

>> Ground Rail Laser Cutting Machine Making Holes and Marking Hot Sale Worldwide

>> Custom Logo Wooden Shoehorn Shoe Horn Beech Wood for Hotel

>> Factory Supply Sesame Butter Making Machine/Peanut Butter Mill Machine /Colloid Mill Machine

>> Pulley Wheel/Drive Belt Idler Pulley/Belt Tensioner Pulley

>> Low Noise Operation PCD Series Channels Three-Side CNC Punching Machine