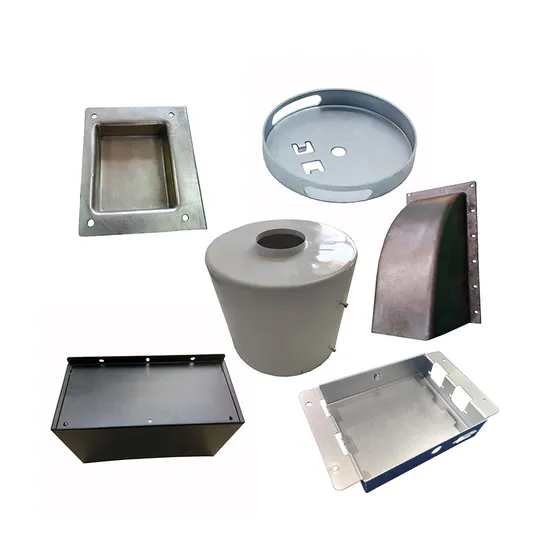

Custom Manufacturer Deep Drawn Square Metal Tank Metal Deep Drawing Parts

| US$0.20 | 10 Pieces (MOQ) |

Basic Info.

Model NO.

deep drawing

Material

Mild Metals

Mould

Multistep Progressive Dies

Surface Processing

Suitable Surface Finish

Fine Blanking

Multi-Position

Process

Forming Process

Industry

Metal Stamping Parts

Tolerances

0.1mm

Customized

Customized

Metal Material

Soft Metals Suitable for Stamping and Drawing

Length or Diameter

up to 500 mm

Width or Diameter

up to 500 mm

Height

up to 500 mm

Wall Thickness

0.5 to 10 mm

Inner Chamfer Radius

Min 2 to 4 mm

Outer Chamfer Radius

Min 4 to 6 mm

Surface Finish

Suitable Surface Finish as Per Requirements

Packing Way

Best Suitable Packing Way

Application

Industrial Components

Transport Package

Plywood Case

Origin

Jiangsu, China

HS Code

8466940090

Production Capacity

100000 PCS Per Month

Product Description

Product Description

| Material | Mild steel, stainless steel, aluminum, brass and so on |

| Dimension-Length/Width/Diameter | 2 to 1000mm |

| Dimension-Height | 2 to 1000mm |

| Dimension-Wall thickness | 0.2 to 20mm |

| Tolerance for dimensions | Follows up ISO2768-2 or GB/T1184 |

| Minimum inner radius | R1-R2 |

| Surface finish | Mill finish, powder coating, anodizing, zinc plated, tin plated and so on |

| Manufacturing process | Stamping, bending, laser cutting, deep drawing, welding, machining, casting, extrusion |

| Application | Industrial fields and household |

| Packing way | Best suitable packing way |

Nanjing Metalli-your ideal partner for thermal management and metal fabrication solutions

Since 2008, Nanjing Metalli has been focusing on thermal management field. Our capabilities cover a wide range that provide you one-stop solution quicker and easier. Our main capabilities include:

1. Vacuum Brazing and Controlled Atmosphere Brazing

2. CNC machining

3. Welding

4. Aluminum extrusion

5. Aluminum die casting

6. Sheet metal fabrication covering laser cutting, stamping, drawing and bending

7. Surface coating

We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

>> a Frame Livestock Machinery Layer Chicken Cage for Poultry Farm

>> High Speed Plastic PE PVC Single Wall Corrugated Pipe Making Machine

>> Inspection Service for Wedding Dress

>> 40mm Center Back Mount Anti-Vibration Pressure Gauge 1.5" Liquid-Filled 230psi/16bar

>> Aluminium Sliding Window

>> Stainless Steel Aluminum Copper Brass Lathe Milling Turning Spare Machining Cutting Anodizing Machine Gear Auto Parts for Special Medical Equipment

>> 5 Gallon PC Bottle Making Machine

>> ERW Square Tube Production Line for Automatic Pipe Welding and Steel Pipe Pipe Make Machine Machine for Plumbing Pipe Steel Pipe Making Machine

>> Wafer Stick Roll Forming Packaging Machine/Full Automatic Snack Egg Roll Machine

>> High Cobalt Diamond Core Drill Bit Segment

>> Rxt Mill Manufacturer - Pulverized Grains for Ultrafine Grinding

>> Jumei Cast Acrylic Sheet Manufacturer Perspex PMMA Transparent Acrylic Sheet

>> Factory direct car body kit tail gate Nissan japan type for Qashqai J11 2015-replacement car body parts

>> Exterior Curtain Wall Decoration Material PE PVDF 4mm Aluminum Composite Panel

>> China Fuanshi Precision Oxygen Probe Meter for Reliable O2 Detection

>> Topmac 250liter Small Hydraulic Concrete Mixer Machine with Hydraulic Hopper

>> Japanese Nissan spare body parts car front bumper support for T31 X-trail 2008 OEM 62030-1DA0A

>> Hot Sell Chicken Plucker Machine Bird Pluking Machine Chicken Slaughtering Machine

>> Dual Shaft Automation Motor 60# 150W Precision for Robotics

>> Mini Crane 600kg Manual Handle Lift Permanent Magnet

>> Wholesale Crystal Decoration Party LED Light Christmas Tree Gifts for Festival Party Decor

>> 16" Big Power 1100W Electric Mobility Scooter Emw35

>> Hot Selling Lan Cable Cat 6 UTP Network Cable Outdoor 305 Meter Cat6 Multi Pair Telecommunication Cable

>> Wholesale Optical Biological LED Light Stereo Monocular Student Lab Microscope

>> Jerry Can 25 Liter Plastic Drum with Pour Spout for Storage

>> Robust 2bg-20 Rotary Tiller with 118-Inch Working Width for Farmers

>> New Model Full Automatic Overlock Sewing Machine (FIT-900D-4UTD)

>> Factory Outlet Liquid Bag Filling Sealing Packaging Machine for Water and Rinse

>> CE Approval 1ton 2ton 3ton Crane Hhbb Electric Chain Hoist with Hook or Trolley

>> Matched Stabolity Sperior Cutting Aluminum Cataran Hull Construction Aquatic Weed Harvester