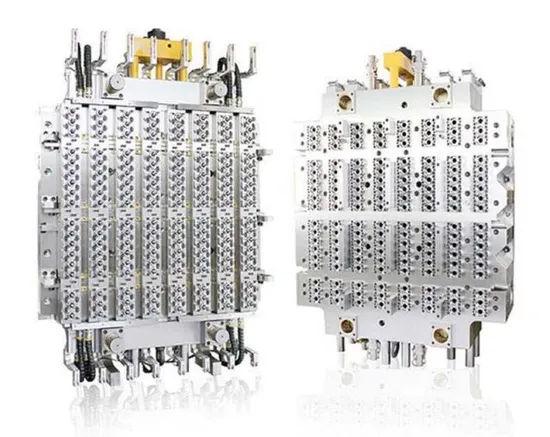

Premium Preform Mold with P20 S136 H13 Steel 3-5 Million Shots

Basic Info.

Model NO.

TH-S2

Material

Steel

Shaping Mode

Injection Mould

Runner System

Hot Runner

Cavity Quantity

48

Certification

CE

Customized

Customized

After-sales Service

Video Technical Support

Mold Plate

P20 Steel S136 Steel H13 Steel

Mold Life Time

3-5 Million Shots

Cycle Time

11-20s

After -Warranty Service

Online Support

Transport Package

Wooden Case

Specification

Customized

Trademark

pairui

Origin

China

Packaging & Delivery

Package Size

80.00cm * 30.00cm * 40.00cm

Package Gross Weight

200.000kg

Product Description

Product Name and Plastic PET Preform Mold Core Cavity Lip Cavity Neck Thread Making: Unleash the full potential of your production line with our expertly crafted PET preform molds, designed to precisely meet your manufacturing needs.

Core & Cavity Steel :

Premium quality steel options including 2316# steel, S136 stainless steel, or tailored selections based on specific customer requirements, ensuring durability and longevity.

Mould Base & Standard Component :

Choose from renowned standards like DME, HASCO, MISUMI, LKM, or opt for our self-made solutions crafted with P20, 3CR13, 4CR13 materials, guaranteeing robust performance.

Steel Hardness :

Maintain structural integrity with base material hardness rated at HRC30-35.

Achieve superior strength with core and cavity material hardness at HRC45-48.

Experience exceptional performance in special parts with material hardness reaching HRC60-62.

Plastic Material :

Versatile compatibility with a range of plastics including PET, PP, ABS, PC, AS, TRITAN, and others, catering to diverse application needs.

Cavity Number :

Available in multiple configurations such as 1*4, 1*6, 1*8, 1*12, 1*16, 1*24, 1*32, 1*48, offering flexibility and scalability to your operations.

Injection System :

State-of-the-art Pnuematic Valve Gate System with shut-off capabilities, offering options for free-cut, short tail, or long tail, enhancing your production precision.

Ejector System :

Enhanced efficiency with Mould Slider and Stripper Plate Ejection, ensuring seamless operations and quicker throughput.

PET Preform Mold Feature

1. Each mold is a masterpiece of engineering with P20 steel plates pre-hardened, and core, cavity, and neck screw crafted from S136 high-strength, anti-corrosive stainless steel. Precision machining ensures concentricity and compact mold structure.

2. State-of-the-art spiral cooling design reduces cycle time, boosts efficiency, and cuts costs. The reliable opening/closing system features a bearing slide type for precise preform drops, with all sliding surfaces inlaid with self-lubricating copper alloys for low friction and wear resistance.

3. Individual self-locking for each cavity assures high precision and minimal defects, facilitating easy disassembly and maintenance.

4. Innovative off-center adjustment system maintains preform thickness difference under 0.10mm. Double cone positioning ensures flawless manufacturing, eliminating flash, size irregularities, and other defects.

5. Expertly designed preforms, crafted via computer-aided design, ensure that final bottles are lightweight yet robust, with optimal thickness and height.

6. Equipped with a hot runner valve gate, eliminating the need for preform tail cutting and reducing labor costs. Standard interchangeable components simplify maintenance and replacements.

7. Featuring China's leading or imported hot runner systems like Yudo, Mastip, or Hasco, each cavity enjoys independent temperature control. Advanced systems minimize AA values and prevent defects, ensuring high-quality plastic products.

8. Unparalleled customer service includes a one-year free warranty and lifelong technical support, ensuring peace of mind and ongoing operational excellence.

| Mold | 24 48 72 cavity PET Preform Mold Can Be Customized |

| Preform Neck | 28mm,30mm |

| Preform Weight | Customized |

| Runner | Hot Runner |

| Core Material | S136 |

| Cavity Material | S136 |

| Screw Neck Material | S136 |

| Mold Base | 4CR13 Steel |

| Mold Life | 5 millions |

| scope of Application | Water bottle |

| Delivery time | 60-70 days |

------Our Partner------

------AFQ------

Q1 :What kinds of product you supply?

A1: Our expansive product lineup includes Sticker Labeling Machines, Shrink Sleeves Labeling Machines, Shrink Wrapping Machines, Injection Molding Machines, Blowing Machines, Filling Machines, Packaging Machines, and a variety of Plastic Products, designed to cater to a multitude of industrial needs.

Q2: How to tell your enquiry?

A2: We warmly invite you to connect with us through your preferred method-be it email, phone call, fax, or instant messenger (Trade Manager, WhatsApp, Skype). Share your inquiry, and we will be delighted to assist you.

Q3: How can I determine the perfect machine for my needs?

A3: Simply share your specific requirements with us, and our expert team will provide you with tailored advice to help you make the best choice.

Q4: Is there technical support available post-purchase of your machine?

A4: Absolutely! We offer comprehensive video and online technical support to ensure your operations run smoothly.

Additionally, if desired, we can arrange for our seasoned technicians to visit your facility abroad. They will provide hands-on guidance and training on installation and maintenance, ensuring optimal performance of your machine.

>> Frosted or Clear Glass Material Candle Jar Decoration Glass Candle Vessels Custom Made Glass Candle Jar

>> Factory Price Profession Drilling Universal Milling Machine

>> Dehydrated Garlic Granules with Roots of Mesh 40-80

>> Mobile Phone LCD Accessory Cell Phone LCD for Huawei X9 LCD Display Touch Screen Digitizer

>> Industrial Double Speed Bakery Used Wheat Flour Spiral Dough Kneading Mixer Machine Baking Equipment Factory Price

>> Schnaider 8 Inputs Isolated Analog Input Module X80 Bmxami0810 Xckmr54D1h29 Xb4BS8442

>> Fenarro Outdoor High-Voltage Isolation Switch for Outdoor High-Voltage Disconnector

>> Hydraulic Steering Riding Type Rice Transplanter Side for Fertilization

>> Double Stage Soft Film Waste Plastic Bag Pellet Making Machine

>> Australian American standards custom security blast resistant aluminium frame curved sliding modern glass windows

>> 84165546 High Quality Auto Car radiator plate support up FOR GMC TERRAIN 2018-2020

>> Quarry Equipment High Quality Kc Series Single Cylinder Hydraulic Cone Crusher

>> Composite Knife Handles Scales Resin Blanks Micarta Material

>> Frosted Glass Jellyfish Desk Lamp for Tea Set Holder Home Office Table

>> 2.0cbm Self Loading Concrete Mixer Truck

>> China 3015 3000W 1530 3kw CNC Laser Equipment Fiber Laser Cutting Machine Price

>> HC-S321 Premium obstetric teaching prenatal care female fundus uterus examination skill training manikin

>> Dish Drainer Rack Dishes Plate Full Body Plastic 2 Tiers Kitchen Rack

>> Yc5801zg-B. Heavy-Duty Deck Mounted Pre-Rinse Unit with Swing Nozzle

>> High Efficiency HEPA Box Deep Pleated HEPA Air Filter for Cleaner Air

>> custom modern high end heavy duty front door residential entry custom security exterior pivot door

>> Stainless Steel perforated metal mesh for walkway or stairs in China

>> Laboao Stainless Steel Bioreactor Fermeration Tank for Bacteria and Cell Culture

>> Hdm301 Insertion Type Nitric Acid Online Tuning Fork Density Meter

>> Jungle Animals Active Theme Large Jumping House Inflatable Bouncer Castle Combo

>> New Catek PRO 80W CNC Cutting Printer Machine DIY Mini Laser Engraving Machines for Wood Plastic

>> System Chameleon Pearl Auto Refinish Paint High Solid Car

>> Guangzhou Auto Parts Car Seat Massage Module For Tesla Model 3 Y 2017-2021+

>> Full Automatic 300G Easy To Eat Vegetables Salad Packing Machine Popular In Supermarket

>> 160t Metal Casting Machine