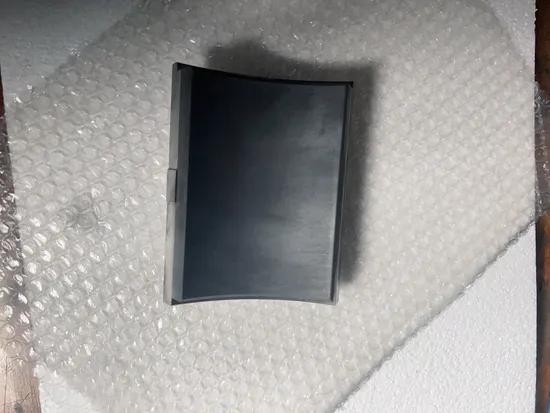

High Purity Graphite Mold for Die Casting and Sintering

| US$5.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

HP-14

Manufacturing Technique

Pressing And Sintering

Available

Available

Material

99.9% High Purity Graphite

Transport Package

Wooden Box

Specification

BIG ADN SMALL

Trademark

ZT

Origin

Qingdao

Product Description

Product Description High Temp Graphite-Graphite Heater For High Temperature And Vacuum FurnacesProduct details:

The graphite heater components are used in the high temperature furnace with temperature reached 2200 degree at vacuum environment and 3000 degree in the deoxidized and inserted gas environment.

Main features of graphite heater:

1. uniformity of heating structure.

2. good electrical conductivity and high electrical load.

3. corrosion resistance.

4. inoxidizability.

5. high chemical purity.

6. high mechanical strength.

The advantage is energy efficient, high value and low maintenance. The graphite heater for electric furnace has properties of heat resistance, oxidation resistance, good electrical conductivity and better mechanical intensity. We can machine various types of graphite heater according to customers' designs.

Graphite Heating Element Product For High Temperature And Vacuum Furnaces Appliaction:

High Temperature and Vacuum Furnaces

Graphite mould plays a dual role in the process of diamond tools manufacture:Heating element

and Supporting mold.The quality of graphite mold is very important, will directly affect the next

diamond tools' accuracy and appearance.So, which kind of graphite mold is suitable for sintering

diamond tools: a: Good performance on conductivity and high rate resistivity

b: Enough Mechanical Strength

c: Good performance on Oxidation resistance

d: Durable Our mold features: Raw materials is very important, We only use Ultrafine particle structure, High purity and High

graphitization raw graphite materials. Our finished graphite mold is: a: dense structure and low porosity

b: Fined surface and low rate heat-deformation

c: High mechanical strength and machining accuracy

d: Oxidation resistance and durable

>> F80 Strong Neodymium Fishing Magnets 250lbs Pull Force

>> 120mm Plastic Sealed Motor Motor Electronic Rotor Accessories Iron Core Fixed

>> China Factory Manufacture Various E Bikes Electric Bicycle Electric Scooter Factory Cheap Electric Motorcycle

>> Thermal Insulation Waterproof Rubber Foam Pipe Insulation Rubber Foam Pipe

>> Free Sample New Style Customized Stone Pattern Aluminum Composite Wall Panels

>> Xiantao Yinhong Protective 3ply Disposable Face Mask Custom Logo

>> Luxury Eco Hotel Prefab Glass Dome Geodesic Waterproof Igloo Dome Tent House

>> Good Tightness 5000 Tons Grain Maize Storage Silos

>> Spindleless Peeling Machine for Plywood Veneer

>> Plastic Recycling Machine Wear Resistance Screw Segment Twin Screw Extruder

>> Functional Fire Retardant Fabric Modacrylic Material for Workwear Garment T-Shirt

>> High pressure industrial water car washer spray gun

>> Semi Automatic 5L 10L Plastic Pet Bottle Making Blowing Machine

>> Paper Machine Guide Roller The Roll of Paper Machinery

>> Farm Cultivator Rotary Tiller Agricultural Mini Crawler Tractor for Sale for Farm

>> Semi-automatic sample weaving machine for yarn testing

>> UL box outside the top one air conditioner

>> Single Lever Water Tap Swivel Spout Brass Pull out Kitchen Faucet

>> Automatic milk filling machine milk package machine pure water filling machine

>> CE Certified Feather Filling Machine Down Jacket Filling Machine

>> New Corp Freshness Potato Frozen French Fries in 7*7mm IQF

>> Flattened Expanded metal BBQ Mesh For Barbecue Grills and Smokers

>> Baseball Softball Net Netting Throw and Field Trainer Ci20289

>> High Speed Automatic Kraft Paper Machine

>> New Stock Arrival Cutting Tool High Quality Material Handheld Concrete Saw

>> Factory Produce Period Swimwear One Piece Swimsuit Leak Proof Period Swim Sport Wear Menstrual Period Swimwear

>> Commercial Grade RO Water Treatment System for Pure Drinking Water 500lph

>> Taijia ZBL-C310A Rebar Corrosion scanner detector price Rebar Corrosion locator

>> New Gold Stamp Non Woven Wallpaper Manufacture Wholesale Home Decorative Wall Paper

>> New 304 Stainless Steel Bottle Portable Insulation for Outdoor Sports