Woodworking Boring Machine Boring and Dowel Machine Multi Boring Machine Price

| US$1,690.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

Concentric Hinge Drilling Machine

Controlling Mode

Artificial

Automatic Grade

Semiautomatic

Precision

High Precision

Certification

CE, ISO

Energy Saving

Energy Saving

Warranty

1 Year

Customized

Customized

Condition

New

After-sales Service

One Year

Name

Concentric Drilling Machine

Power Supply Voltage

380V/50Hz (Three-Phase)

Single Motor Power

2.2kw

Pressing Air Pressure

0.3-0.4MPa

Maximum Size

1700X1000X1700mm

Workbench Size

1500X700mm

Total Power

4.4kw

Spindle Speed

2870 R/Min

Working Air Pressure

0.5-0.7MPa

Number of Spindles

2

Weight

280kg

Transport Package

Wooden Box

Specification

1800*1100*1850mm

Origin

China

Production Capacity

10sets/Month

Packaging & Delivery

Package Size

180.00cm * 110.00cm * 185.00cm

Package Gross Weight

280.000kg

Product Description

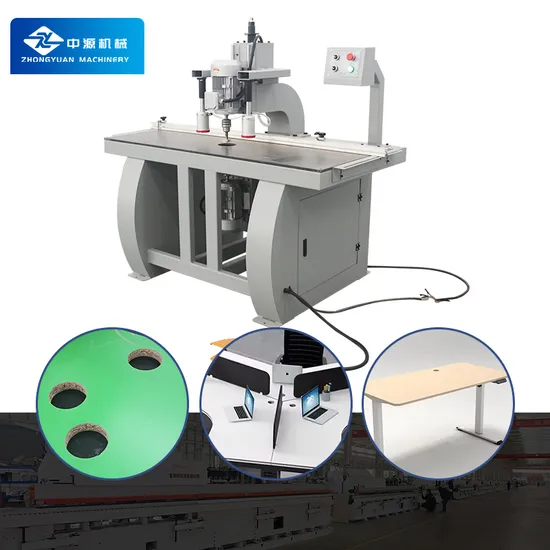

Product ParametersConcentric drill:Drilling up and down, forming in one go, equipped with pure copper motor and durable alloy drill bit.

1.Double guide rail:Thickened guide rail, punching does not shake, stable performance to ensure accurate movement and adjustment of the vertical axis, low noise, easy replacement of drill bag.

2.Pure copper motor:Powerful power, good heat dissipation, stable output.

3.Wear-resistant cutter head:High hardness and wear-resistant metal, high hole depth accuracy, smooth operation, high punching accuracy, one-time forming.

4.Cylinder pressing device, tightly presses the plate, the plate is stable and does not deviate during operation, preventing wrong operation.

5.Positioning baffle:Solid aluminum alloy ruler with positioning caliper, precise scale, can be adjusted according to work needs, accurate positioning.

6.Control panel:Independent buttons, clear markings, avoid wrong operation, simple and convenient.

7.Foot switch:Foot pedal control, safe and labor-saving, easy to operate.

8.Thickened frame:Beautiful and elegant, novel design, high manufacturing accuracy, convenient and flexible operation, stable and reliable operation, high work efficiency.

| Power supply voltage | 380V/50Hz (three-phase) | Total power | 4.4KW |

| Single motor power | 2.2KW | Spindle speed | 2870 r/min |

| Pressing air pressure | 0.3-0.4Mpa | Working air pressure | 0.5-0.7Mpa |

| Maximum size | 1700x1000x1700mm | Number of spindles | 2 |

| Workbench size | 1500x700mm | Weight | 280kg |

Detailed Photos

Product Application

Company Profile

Certifications

FAQ

Q1: I already have an edge banding machine and I would like a trimming machine. Do you have any recommendations?

A: Yes, we have a matching trimming machine. You can choose the product that suits you according to your actual production needs. Of course, we will also ask you some questions, such as plate size, plate thickness, equipment voltage, number of workers, and so on. With so many types of products, there is always one that is suitable for you.

Q2: Can your edge banding machine use PUR adhesive?

A: PUR glue has high requirements for glue pots. We recommend using models such as F14620-3700-3350 for up glue pots, depending on your specific needs.

Q3: Are you a factory or a trader?

A: We are a 20 year source production factory with rich production experience and a total of 8000+customers. We can provide you with thoughtful and accurate after-sales service.

Q4: How should I make the payment?

A: Firstly, you will pay a 50% deposit as a prepayment, and then we will start producing the equipment. After the

equipment is completed, I will send you photos and videos, and you can make the remaining payment. After receiving all the payment, we will arrange for the fastest container to ship to you. You will receive the equipment soon, and I will arrange professional technicians to coordinate with you regarding installation issues.

Q5: How long is the delivery time?

A: Conventional equipment takes 10-12 days, customized voltage or other parameters take around 30-45 days.

>> Horizontal/Vertical Universal Rotary Worktable Milling Machine

>> Food Grade Conveyor System for Beverage Industry Applications

>> Ama Vr Multiplayer 9d Cinema Rotation Roller Coaster 360 Degree Reality Virtual Simulator

>> Taijia ZD310 Concrete Rebar Scanner Ferro Scanner Metal Detector Ferro Scan Rebar Locator

>> Wholesale Kd-Zg100 Automatic One Time Paper Cup Lid Making Machine Price

>> New Condition CNC Hydraulic Press Brake Carbon Steel Processing High Productivity with Synchronized End Forming Services

>> Lathe for Turning Wood Automatic CNC Machine CNC Wood Turning Lathe Cutter Wood Lathe

>> Orange juice press, manual juicer, extruder, multi-function lemon juice press juicer

>> A62 Multifunction 2 Pins Wall Socket with Indicator Lighter

>> Jy-Scz2+ Mini P Electrophoresis Machine Gel Electrophoresis Equipment for Hemoglobin Detecting Vertical Electrophoresis Tank, Hospital Equipment, SDS-Page

>> Hot Sell Type C Wax Injection Machine for Precision Casting

>> Power Single Phase Automatic Voltage Regulator Stabilizers AC Home Use Relay Type

>> Guitar Cable Nylon 10FT 1/4 Inch 6.35mm Gold Straight Ts to Ts Electric Guitar and Bass Audio Cord Professional Instrument Wire OFC CCA 22/24 AWG Guage Colors

>> 20HP 4-Stroke Outboard

>> Premium Mecair Diaphragm Repair Kits for dB Series Models

>> Decorative Aluminum Sun Louver Outdoor Vertical Metal Facade Building

>> World Well-Being Biotech Natural Hawthorn Extract with 10%-80% Flavonoids for Supplement

>> 210liter Open Top/Chemical/Drum/Bucket/Barrel/Drum/Container/Blow Moulding Machine/210L Top Open Drum-Blow Molding Machine

>> Home Bowl Dish Cleaner Balls Stainless Steel Wire Rope Cleaning Tool

>> Sanki Classic 56 High Quality Six Nozzles Fuel Dispensers with Good Quality

>> Professional Manufacturer Die Cutter with Sheet Paper Cutting Machine Safety Cover on Cutting Knife Sizing Cutting PVC,PP 600mm

>> 0-12.7mm/0-0.5′ ′ Digital Dial Indicator with 0.01mm/0.0005′ ′ Resolution Measuring Device

>> Hinwin/PMI Linear Way/Ball Screw CNC Vertical Automatic Milling/Machine Center/Tool Vmc850/1160/1270/1370/1580/1690/1890 CNC Vertical Machining Center Lathe

>> Genuine Body Kits For Volkswagen Tiguan Change R-line Front Car Bumpers With Grille Wheel Arches License Plate Rear Diffuser

>> White 60 Inch 1.5M Retractable Ruler Tape Measure Sewing Cloth Dieting Tailor Plastic Fitness Accurate Body Measuring Tape

>> New Angel Marble Carved Statue Outdoor Garden Sculpture Buddha for Sale

>> Car Back Door Panel Trunk Lid for Vios 2008-2013 NCP92 Yaris 2008 64401-0D110 Auto Spare Body Parts

>> Hot Selling Custom Design Goalkeeper Sport Shirt Soccer Wear Goal keeper Shirt

>> 5L-1500L Heating Cooling Vacuum Silicone Sealant/Putty/Plasticine/Lithium Battery Paste Dual Shaft Triple Shaft High Speed Disperser Dissolver Planetary Mixer

>> Durable Lyre Harp Shoulder Bag for 7-String, 10-String, 16-String Models