High Efficiency Decanter Centrifuge for Dewatering and Solid-Liquid Wastewater Treatment Solutions

| US$15,000.00-80,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LW Series

Operating Type

Continuous Type

Installation

Horizontal

Centrifuge Type

Horizontal Spiral Centrifuge

Pressure

Low Pressure

Condition

New

Material

SS304 or SS316 L or Ti

Feature

High Efficiency

Separation

2 or 3 Phase Separation

Discharge Type

Self-Cleaning

Separation Method

Sedimentation Type

Control

PLC Control

Electronic Component

ABB or Siemens

Application

Solid Liquid/Liquid-Liquid-Solid Separation

Transport Package

Wood Case

Trademark

JIANENG

Origin

China

Production Capacity

500/Year

Packaging & Delivery

Package Size

600.00cm * 150.00cm * 180.00cm

Package Gross Weight

7000.000kg

Product Description

Company Profile Jiangsu Jianeng Machinery Manufacturing Co., Ltd. stands as a beacon of innovation and excellence in the high-tech manufacturing realm, proudly under the full ownership of Nanjing Jianeng Machinery Manufacturing Co., LTD. Since our establishment in 2001, we have distinguished ourselves in the art of research, design, manufacturing, and service. Originally founded in Nanjing Yuhuatai District, we have expanded into an ultra-modern facility strategically positioned at Jinyuan Road No. 7, Xuyi Economic Development Zone, Huaian City, Jiangsu. This impressive complex covers a vast area of 58,700 square meters, featuring a 38,600-square-meter workshop, an elegant 4,000-square-meter office building, and a 2,100-square-meter science and technology building. With an unwavering commitment to crafting China's most superior disc and decanter centrifuges, our annual production capacity soars to an astounding 2,000 sets.

Main technical parameters ofdecantercentrifuge | ||||||

Model | LW250 Series | LW350 Series | LW450 Series | LW530 Series | LW580 Series | LW650 Series |

| U. mm Drumdiameter | 250 | 350 | 450 | 530 | 580 | 650 |

| m³/h Water lux | 3 | 10 | 20 | 30 | 40 | 50 |

U. w Main motor power+ Auxiliary motor power | 15+4 | 22+7.5 | 30+11 | 45+15 | 55+15 | 75+22 |

| U. kg Weight | 1100 | 2300 | 4500 | 5500 | 6500 | 9500 |

| U. m Overall dimension | 2.7X0.7X0.85 | 3.54x0.92x1.05 | 4.35x1.12x1.35 | 4.6x1.25x1.52 | 5.12x1.3x1.48 | 5.58x1.35x1.65 |

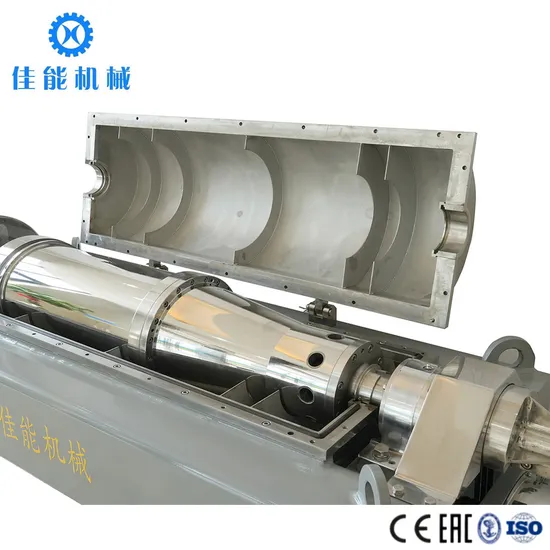

Typical Structure of Decanter Centrifuge Drum

The decanter centrifuge, often referred to simply as the 'decanter,' is ingeniously engineered with essential components such as the drum, screw, differential, frame, and cover. During operation, both the drum and screw rotate in harmony, maintaining a specific differential speed for optimal efficiency.Material is seamlessly introduced into the inner spiral cylinder via the feed pipe, where it is rapidly accelerated into the rotating drum. Within this dynamic environment, centrifugal force compels the denser solid particles to settle along the drum's wall, creating a distinct sediment layer. The screw diligently transports this sludge towards the drum cone's endpoint, where it is proficiently expelled from the machine through the designated discharge outlet.Simultaneously, the lighter liquid phase gracefully forms an inner liquid ring, which effortlessly cascades through the overflow port located at the drum's larger end, elegantly draining from the machine via the drain port. This process achieves a flawless liquid-solid two-phase or liquid-liquid-solid three-phase separation.

Procedure Control

At Jiangsu Jianeng Machinery, we take immense pride in our sophisticated quality inspection and test center. Equipped with cutting-edge instruments like chemical analyzers, product test benches, high-precision dynamic balances, coordinate measurement machines, Vickers hardness testers, imagers, flaw detectors, profilers, and coding machines, we ensure each product meets the pinnacle of excellence. Our rigorous and comprehensive testing procedures, paired with state-of-the-art equipment, certify outstanding product quality and dependability throughout every phase of manufacturing.

Product Equipment

Jiangsu Jianeng Machinery is equipped with a comprehensive range of advanced production capabilities, including machining, surface treatment, cold welding, testing, test stands, installation, and commissioning. Our leading-edge facility hosts over 300 pieces of state-of-the-art equipment such as CNC boring and milling centers, CNC turning centers, gantry machining centers, advanced testing tools, parts painting production lines, shot peening production lines, welding equipment, surface treatment machines, and high-precision dynamic balancing equipment. This vast collection of machinery empowers us to maintain complete process independence, guaranteeing unmatched product quality. With top-tier processing and testing equipment, a team of highly skilled technical personnel, scientific manufacturing methodologies, and strict adherence to national military standards and quality management systems, we uphold our foundational principles of 'management, quality, and efficiency' throughout all business operations.

One-stop Services

We provide a comprehensive suite of one-stop services, including a generous supply of spare parts, expert commissioning, repair, maintenance, and professional technical consultations, all aimed at supporting our esteemed customers. Sufficient Spare Parts and Standby Machines

Our strong, independent production capabilities across the entire process empower us to consistently deliver superior products, not just meeting but surpassing industry standards.

Typical Structure of Decanter Centrifuge Drum

The decanter centrifuge, often referred to simply as the 'decanter,' is ingeniously engineered with essential components such as the drum, screw, differential, frame, and cover. During operation, both the drum and screw rotate in harmony, maintaining a specific differential speed for optimal efficiency.Material is seamlessly introduced into the inner spiral cylinder via the feed pipe, where it is rapidly accelerated into the rotating drum. Within this dynamic environment, centrifugal force compels the denser solid particles to settle along the drum's wall, creating a distinct sediment layer. The screw diligently transports this sludge towards the drum cone's endpoint, where it is proficiently expelled from the machine through the designated discharge outlet.Simultaneously, the lighter liquid phase gracefully forms an inner liquid ring, which effortlessly cascades through the overflow port located at the drum's larger end, elegantly draining from the machine via the drain port. This process achieves a flawless liquid-solid two-phase or liquid-liquid-solid three-phase separation.

>> Structure Building Chicken Farm Poultry Prefab House Retech Layer Broiler Multifunctional Provided Chicken Coop Farming Steel

>> Waterproof IP65 Single Infrared Beam BS-20 Sensor

>> Custom Irregular Arch Oval Rectangle Cosmetic Vanity Wall Mounted Decoration Framed Mirror

>> G20 G28 Front Bumper Center Lower Grille Cover Air Inlet Vent 51118075642

>> Custom low moq color Printing color 250g 500g 1kg coffee stand up pouches

>> Andeli Adm3 250L/3300 MCCB Circuit Breaker

>> best price popular cute design gasoline sightseeing car

>> Hzs180 180m3/H Fully Automatic Ready Fixed Concrete Mix Mobile Stationary 25m3/H to 240m3/H Capacity Concrete Mixing Plant

>> Modern Aquatic Plant Harvester for Efficient Water Hyacinth Removal

>> 1325 Stone CNC Router for Engraving Marble with Water Cooling Spindle

>> Qt4-20 Cement Cement Brick Making Machine Semi Automatic Prices for Sale

>> Good price mole removal double handle ozone plasma jett pen beauty machine for sale

>> Genie S65 Small Man Lift Electric Battery Drive Articulating Boom Lift

>> Rhinoceros Xn20b CE EPA Mini Excavator Price 2 Ton Digger

>> Round Biodegradable Eco Friendly Scented Tea Paper Tube Packaging with Custom Logo Printed and Matte Vanish

>> High-Tech Hqt300L-1000 Bed Lathe Import Turning CNC Lathe Machine

>> Original brand DKYT colouring stainless steel skeleton automatic women mechanical watch

>> 90/100/160L Banbury Kneader Machine Powder Weighing System

>> Plastic Granules PP PE Pet Mixing Storage Tank Material Plastic Color Mixer

>> Durable Ductile Iron Square Manhole Cover for Drainage Systems

>> Dynamic Cone penetrometer Test DCP

>> Xpz 500L Laboratory Automatic Glassware Washer with Two Doors Can Open in Clean and Non-Clean Areas

>> Huatai Solar Panel Lamination 5V 1W Monocrystalline/ Poly with ETFE Lamination Solar Panel with Cable Customized Sizes

>> Durable Tata Farm Machinery Parts of Compressor Piston Connecting Rod for Ks

>> Factory Direct Sale High Quality Bamboo Tensoge Chopsticks for Restaurant

>> Hot Press Machine, Used in Plywood Production, Blockboard Production, Decorative Board Production

>> Heavy-Duty Waterproof Automotive Connectors for Secure Plug Connections

>> Brushless Motor Powerful Electric Cordless Wrench-18V Cordless Power Tool Family

>> W11s-16*2500 Plate Rolling Machine Sheet Metal Bending Machine

>> Mornsun AC/DC 35W Enclosed Switching Power Supply