Hc/HD/Ld High Consistency Cleaner for Paper Making Machine Slag Remover

| US$666.00-6,666.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

JSD

Certification

CE

Surface Treatment

Spray-Paint

Manufacturing Process

Cnc Milling

Material

Stainless Steel

Flow Rate

800-12000(L/Min)

Consistency of Inflow Pulp

2-5%

Pressure of Inflow Pulp

0.2-0.35MPa

Tapping Mode

Automation Manual

Transport Package

Wooden Case

Specification

customized

Trademark

JINSHENGDA

Origin

Henan, China

HS Code

8439910000

Product Description

High Consistency Slag Remover Product Description Highly concentrated desludger is to use the different specific gravity of fiber and impurities to separate impurities. Slurry with a certain pressure from the feed tee tangent into the slag remover after high-speed rotation, due to the difference in centrifugal force, the heavy impurities are thrown to the wall, under the action of gravity, gradually run to the bottom of the cone, into the sedimentation tank. Fiber due to the smaller centrifugal force, gradually run to the center of the low-pressure area, after reaching the bottom of the vortex rise, and finally discharged by the mouth of the good pulp. The cone of the high-density deslimber has a certain taper, and the cone is longer, the radius of rotation of the pulp in the cone is gradually reduced to avoid the speed of the pulp flow in the process of rotation is reduced to ensure that the centrifugal force is strengthened, thus improving the purification efficiency of the paper material. The bottom balance of water pressure is slightly greater than the pulp pressure, so that the fiber can not enter the slag tank, only sand, metal particles, glue, plastic and other heavy impurities sink into the tank, reducing the loss of fiber.Detailed Photos

Product Parameters

| Type | ZSC2A | ZSC3A | ZSC4A | ZSC5A | ZSC6A | ZSC7A |

| Flow rate(L/min) | 800-1600 | 1500-2800 | 3000-4800 | 4500-5800 | 5800-7500 | 8000-12000 |

| Consistency of inflow pulp(%) | 2-5 | |||||

| Pressure of inflow pulp(Mpa) | 0.2-0.35 | |||||

| Tapping mode | Automation manual | |||||

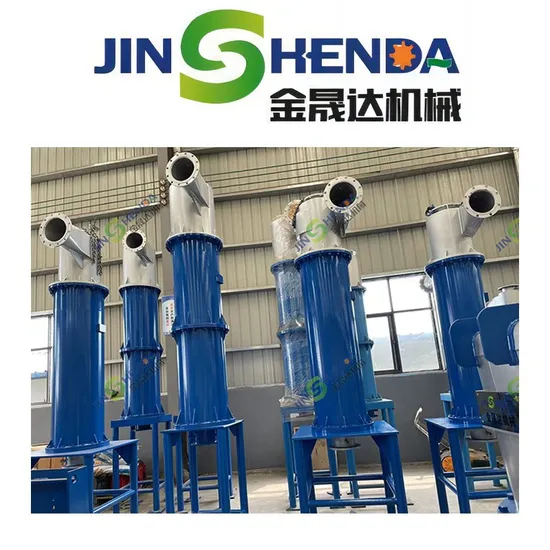

Work shop

Company Profile The company has always been market-oriented, specializing in the development of pulp crushingequipment, slag removal equipment, screening equipment, pulp grinding equipment, waste paper plasticpackaging machine and other complete sets of pulp and environmental protection equipment. The company coversan area of more than 10000 square meters, with a construction area of 8000 square meters, and more than 200employees. It has excellent CNC machining equipment and advanced product testing and inspection instruments.It has strong technical force and annual production capacity of more than 8000 tons.

The company has more than 30 provinces, cities and autonomous regions, and is exported to Egypt,Vietnam, India, Indonesia, Iran, Malaysia, Russia and other countries and regions, and is highly praised andtrusted by domestic and foreign users.

Travel far from you, pursuit endless, Jinsheng Da machinery will continue to work hard, to serve theindustry Monument and forward.

After Sales Service Before Purchase: 1.Help customers find the right product by professional technology and business consultation 2.Provide plans of the machines installation freely3.Make customized products according to the clients requirements 4.Online for 24 hours After Purchase: 1.Fast and saft delivery 2.Assist our clients to bulid the equipment3.Train the first-line operators on site 4.Regularly visit clients to solve production problems5.Online for 24 hour

>> Innovative Parallelogram Mounted Reversible Pivot Plow for Agricultural Work

>> 10 Inch 300W High Performance New Fashion Home Theater Active Heavy Subwoofer Active Speaker for Arbitrary Connection

>> Liquid Fertilizer Calcium Thiosulphate

>> Water Cooling ISO 9001 Approved Inte Aluminum Sheet Drill Machine

>> Factory galvanized steel stucco wire mesh with professional experience

>> Protect your cells from oxidative stress three-in-one 300ml Hydrogen Gas Inhalers 150ml Hydrogen Gas Inhalers

>> Cryo Body Shape Cryolipolysys 4 Handles 360 cryolipolyses Fat Cell Body Slimming Machine Criolipolisis

>> Women Ladies′ Rain Jacket Dust Coat with Mesh Lining Windbreaker

>> IP/WiFi Touch Screen System Smart Wireless Remote Control Video Doorphone Intercom

>> Package Lab Consumable PP Disposable Medical Supplies 1250UL 96 Wells Pipette

>> Best Sale M3-M16 Servo Automatic Flexible Arm Electric Tapping Machine

>> Walking Pad Home Fitness Foldable Smart Treadmill

>> Automatic Small Wrapping Packing Machine Flow Horizontal L Type Wrap Sealing and Cutting Machine

>> China Wholesale Luxurious Bedding Textile Raw Silk Filament Thread

>> EPS Foam High Quality Sandwich Panel Manufacturing Line

>> China Factory Automatic PLC Control Stainless Steel Stone Wax Plate Wax Forming Machine

>> Incubator 10000 Eggs Chicken Hatching Machine for Eggs Incubator in UAE

>> Plastic Shredder for Recycling Waste Drum/ Plate/ Barrel

>> 7/16" Dia 4 3/4" Long Hot DIP Galvanized J Hook Drive Hook

>> OEM Embroidery Logo Cotton Material Head Sweatband

>> 85 Inch Interactive Flat Panel Multi Writing Interactive Smartboard Whiteboard

>> Top Quality 600X600 Indoor Ceramic Polish Floor Porcelain Tile

>> Taijia Tmeasuremen zbl r800 Ferroscan detector rebar locator price concrete scanner rebar locator

>> YZFG600 High Speed Automatic Pre-fold Medicine Paper Box Folder and Gluer Machine

>> Spices Sichuan Pepper Supplier

>> Aluminum burglar room folding glass partition black bifold sliding french doors

>> Cushioning Wrap Honeycomb Paper Making Machine

>> Mini Coromant CNC laser 50W/100W Fiber Laser Technology Makers Engraver/Cutting/Marking/Rust Cutter/Bending Machine for Metal Decorative Plate

>> Module spare parts FLN4234A

>> Wholesale AC 220V Computer US power Cord C13 1.5M 1.8M 3 PIN Power Cord for laptop