Dyes High Speed Mixer Dispersing Machine Homogenizer with Digital Display

| US$10,000.00-100,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

IMS4

Application

Granules, Liquid, Liquid with Suspended Solids, Powder, Viscous Fluid

Application Area

Chemical

Certification

CE, ISO

Condition

New

Mixing Drum Shape

Circular Groove

Stirring Type

Forced

Warranty

1 year

Working

High Speed Mixer

Power

22-37 Kw

Maximum Rotation Speed

3000 Rpm

Processing Volume

1500-8000 L

Powder Suction Speed

3-10 Kg/Min

Maximum Viscosity

100000 MPa.S

Layout Type

Horizontal

Operating Type

Cycle Operating

Mixer Type

Inline Mixer

Transport Package

to Order of The Customer

Specification

To order

Trademark

Hoosun

Origin

Shanghai, China

HS Code

84798990

Production Capacity

1000 Pieces/Year

Product Description

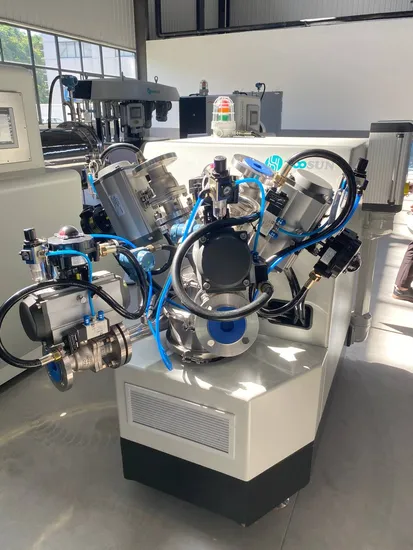

Product Description: Inline Dispersing and Mixing Equipment IMS4Product Description: The IMS4 Continuous Dispersing and Mixing Equipment is designed for efficient and precise mixing of liquids with suspended solids, powders, viscous fluids, and granules. This advanced mixer is ideal for various industries, including chemical, paint production, coatings, dyes, pigments, and graphite.

Application Areas:

Micro and nano materials Ceramic materials Battery homogenization Conductive materials Digital inkjet Coatings and inks Key Features and Benefits:

High Efficiency: The IMS4 provides high-speed mixing and dispersion, achieving uniform particle distribution and material homogeneity. Versatility: Suitable for a wide range of materials and processes, from chemical industries to digital printing. Energy Efficiency: Advanced vacuum dispersion technology reduces energy consumption by more than 70%, leading to significant savings. Automation and Ease of Use: Easily integrates into automated systems, ensuring stable and reliable operation with minimal operator involvement. Durability and Reliability: Constructed with high-quality materials, ensuring long service life and stable operation. Technical Specifications:

Power (kW): 22-37 Maximum Rotation Speed (rpm): 3000 Processing Volume (L): 1500-8000 Powder Suction Speed (kg/min): 3-10 Maximum Viscosity (mPa.s): 100000 Liquid Flow Rate (m³/h): 30-50 Suspension Flow Rate (m³/h): 30-50 Unique Technologies:

Special stator-rotor design ensures high-speed shear slurry and uniform particle distribution. Vacuum powder suction without loss and closed chamber to prevent leaks and contamination. Savings and Efficiency:

Energy-saving technologies reduce production and operational costs. High dispersion efficiency ensures superior product quality. After-Sales Service:

Professional installation and commissioning. Lifetime technical support and maintenance. Conclusion: The IMS4 is a reliable and highly efficient solution for mixing and dispersion in various industries. Its advanced technologies, energy efficiency, and ease of use make it an indispensable tool for your production needs. Contact us for more information and to place an order!

Technical Specifications Table for IMS Models:

| IMS1 | 3 | 8000 | 20-500 | 1-4 | 60 | 10-20 | 2-4 |

| IMS2 | 3-7.5 | 6000 | 100-200 | 4-12 | 100 | 15-30 | 5-10 |

| IMS3 | 11-18.5 | 4000 | 200-1500 | 6-20 | 200 | 20-30 | 10-20 |

| IMS4 | 22-37 | 3000 | 1500-8000 | 3-10 | 100000 | 30-50 | 30-50 |

| IMS5 | 45-90 | 3000 | 8000-15000 | 10-30 | 100000 | >80 | 40-60 |

| IMS-Plus | 75-110 | 1950 | 8000-15000 | >100 | 100000 | >100 | 50-80 |

| IMS6 | 110-160 | 3000 | 15000-25000 | 1-5 | 300000 | 50-80 | 60-100 |

| IMS7 | 200-250 | 3000 | 25000-40000 | 5-30 | 300000 | 60-100 | 60-100 |

Company Profile

Exhibition

CE & ISO certification Signing Ceremony & After-sales service

Our Customer FAQ

>> Modified Matrix scan full led streamer turns headlamp headlight for Buick GL8 head lamp head light 2011-2019

>> Fitness BMI Measuring Tool Black Slim Guide Skinfold Body Fat Caliper Set With Measure Tape

>> Factory Customized Heavy Duty Eye Hooks Screw Stainless Steel Eye Hook Screws Self Tapping Eyelet Screw in Eye Bolt for Wood

>> Aluminium Sliding Window bullet proof sliding window vertical sliding wood window

>> 110V60Hz Fan for Condensing Unit

>> Aluminum alloy sliding window cost-effective product quality is good welcome inquiry

>> Wholesale Car Auto Spare Body Parts Engine Hoods For Benz A CLASS W177 Upgrade A45 Model Aluminum Iron Engine Hood Engine Cover

>> Villa House Damp-Proof WPC Door Moistureproof WPC Plastic Door with Custom Made

>> Fiber Breakout Cable Indoor Multi Core Micro Optical Cable

>> Factory Price Good Quality Luxury Genuine Leather Men Duffel Bag

>> Industrial Hot Sellling Building Material Anti-Static Access Floor PVC Panel for Computer Room, Data Center

>> 2xz Direct Drive Rotary Vane Vacuum Water Pump

>> China Ck6180 8 Position Tool Turret Fanuc CNC Lathe Machine

>> TG1858 Timing Gear for Mercedes-Benz W204 Engine M271 OEM A2710521903 2710521203

>> Classic Rigid Tape Fitness Workout Athletic Sport Tape Weightlifting Boxing Thumb Tape

>> Receipt Paper Durable POS Thermal Paper Rolls for Cash Registers 57X40mm

>> Goldmoon Low Speed Artificial Color Box or Blow Mould Case Stone Cutting Tile Cutter Machine

>> factory supply EPS Foam Plastic Granulator Recycling Machine Pelletizing Production Line for sale

>> 178f 9.0HP Diesel Rotary Cultivator Power Tiller

>> Factory Price Titanium Dioxide CAS 13463-67-7

>> Wireless Motion Sensor Light IP44 Waterproof Security Lights

>> Customized Expanded aluminum foil mesh in Engine crankcase

>> Reliable Primary Small Mobile Jaw Crusher Machine Hot Sale Stone Crusher Machine for Sale

>> LPG 30 Ton Gas Storage Cooking Tank for Sale

>> 500-2000kgs Capacity Pellet Machine and Mixer for Animal Feed

>> Electric Motor Shaft Custom Automobile Wiper Motor Carbon Steel Shaft

>> Reliable Aluminum Folding Glass Bifold Patio Doors for Long-Lasting Performance

>> 16m China Small Towable Articulated Cherry Picker Trailer Mounted Boom Lifts with New Design

>> Industrial Food Powder Cryogenic Grinder Machine Spice Pulverizer Cinnamon Grinder Machine

>> Rt Quicj-Drying Gel Pens Office and School Use