Famou Pig Equipment 60mm Automatic Feeding System Drive for Feeding

Basic Info.

Model NO.

60mm Chain-Disk Feeding System

Application

Chicken

Power Source

Gasoline

Heating and Ventilation Equipment Type

Air Duct

Epidemic Prevention Equipment

Mobile Vaccination Car

Blade Type

Straight Teeth

Computerized

Computerized

Certification

QS, GMP, ISO9001:2008, CE

Condition

Used

Product Name

Chain Disk Feeding System

Keywords

Chain Disk Feed Delivery System

Voltage

380V

Frequency

50Hz

Chain Disc

60mm

Shell

Stainless Steel

Shell Wall Thickness

1.5mm

Feed Tube

275G/M2 Galvanized

Wall Thickness

1.5mm

Power

1.5kw-2.2kw

Protection Level

IP55

Conveying Speed (Horizontal)

1500kg/H

Maximum Conveying Distance

300m,360m

Feature

Save Time and Save Breeding Cost

MOQ

1 Piece

Transport Package

Standard Shipping Packaging or Customized

Specification

Standard or customized

Trademark

FAMOU

Origin

China

Production Capacity

3000set/Month

Product Description

FAMOU Pig Equipment 60mm Automatic Feeding System Drive For FeedingProduct Description

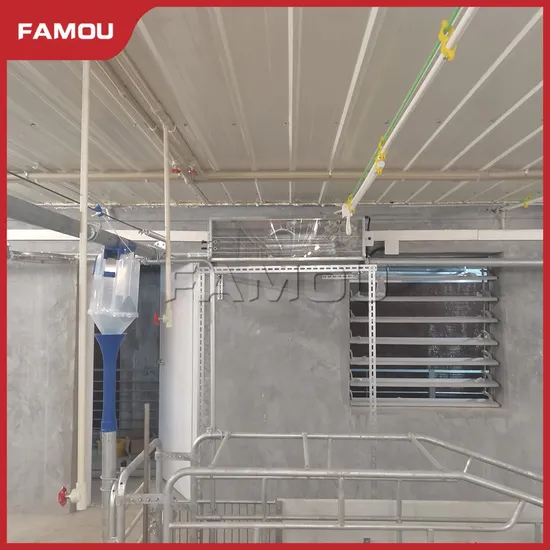

The pig disc chain automatic feeding system is a modern and advanced feeding equipment used in pig farming. This system consists of a network of pipes, rotating discs, chains, and feeding stations that work together to deliver precise amounts of feed to the pigs at designated locations.

The system is automated and programmed to distribute the feed accurately to each feeding station in the pig barn. It operates by conveying the feed through the pipes, rotating discs, and chains, delivering the feed to the feeding stations in a controlled and efficient manner.

The feeding system can be customized to meet the specific dietary needs of different groups of pigs, ensuring that each pig receives the appropriate type and amount of feed. This personalized feeding approach helps in improving the health and growth of the pigs.

The pig disc chain automatic feeding system streamlines the feeding process on the farm, reduces labor requirements, and enhances efficiency and productivity in pig farming operations. It represents a technological advancement in pig farming that contributes to better management practices and improved overall performance of the farm.

Product Parameters

| CHAIN DISK FEEDING SYSTEM SPECIFICATION | |

| Product Name | Chain Disk Feeding System |

| Keywords | Chain Disk Feed Delivery System |

| Voltage | 380V |

| Frequency | 50Hz |

| Chain Disc | 60mm |

| Shell | Stainless Steel |

| Shell Wall Thickness | 1.5mm |

| Feed Tube | 275g/m2 Galvanized |

| Wall Thickness | 1.5mm |

| Power | 1.5kW-2.2KW |

| Protection Level | IP55 |

| Conveying Speed (Horizontal) | 1500kg/h |

| Maximum Conveying Distance | 300m,360m |

| Feature | Save Time and Save Breeding Cost |

| MOQ | 1 Piece |

| Voltage | Power | Protection Level | Conveying Speed (Horizontal) | Maximum Conveying Distance | Galvanized Pipe |

| 380V/50Hz | 1.5kW | IP55 | 1500kg/h | 300m (12 corners) | Φ60*1.5 |

| 380V/50Hz | 2.2KW | IP55 | 1500kg/h | 360m (12 corners) | Φ60*1.5 |

Product Structure

Drive Unit

A steel sprocket wheel drives the chain as it passes through the drive unit while the chain tensioner assembly maintains proper tension on the chain for optimal performance

Two safety switches; one located on the chain tensioner and the other on the access cover, prevent chances for injury or damage to the system's components

A clamping safety rod provides additional increased operator safety compared to cable or spring options when the drive unit is open

Disk Chain

Systems feature superior grade hardened steel chain that is stronger than galvanized chain, which is weakened by heat during the galvanizing process

Our multi-directional chain cannot be incorrectly installed and eliminates the need for frequent tightening common with cable style systems

The low friction disks gently convey all common pig ration mixtures while minimizing damage or feed separation compared to flexible auger systems

Clean Corner Wheel

The black corner wheel housing is fabricated from a tough reinforced polymer with a dome peaked lid to prevent the accumulation of water or moisture

The transparent swing down door is molded from impact resistant polycarbonate with 3 toggle latches that hold it securely in place

Molded metal inserts with rubber seals reinforce critical axle wear points to prevent cracking and eliminate moisture from entering the housing

Durable Corner Wheel

The corner wheel housing is constructed of durable, heavy-duty fiberglass reinforced polymer, which is stronger than polypropylene and designed to withstand years of constant use in production environments

A heavy cast iron corner wheel turns on a stainless steel axle and a low-friction, encapsulated ball bearing

The self cleaning design prevents feed build-up in the wheel housing providing long-term reliability

Proximity Switch

Nursery and finishing pigs can be sorted from any pen as needed since it doesn't rely on a hopper/feeder switch to activate feed cycles Empty farrowing rooms or stalls will not create issues with pig movements and feed availability

Feed availability is easily controlled at each individual output location by opening/closing the feed drop or sow drop

Available kit and replacement parts install directly on the feed line for easy access and adjustment

Details

Company Profile

FAQ

Q1: Are you a trading company or a manufacturer?

A1: We are a factory.

Q2: What are your terms of payment?

A2: Payment <= 5000 USD, 100% in advance. Payment > 5000 USD, 30% T/T in advance, with the balance due before shipping.

Q3: How long is your delivery time?

A3: Generally, it is 20-40 days, depending on the quantity.

Q4: Do you provide samples?

A4: Yes, we offer the sample.

Q5: Whether you could make our brand on your products?

A5: Yes. We can print your Logo on both the products and the packages if you can meet our MOQ.

Q6: Whether you could make your products in our color?

A6: Yes, The color of products can be customized if you can meet our MOQ.

Q7:What can you buy from us?

A7:poultry farming equipment, pig farming equipment, Breeder Farming Equipment, Layer Cage Equipment, Broiler floor breeding equipment

>> Elevated Efficiency in Plastic Recycling Facilities: Integrated Metal Sorting for Pet HDPE PP ABS UPVC Products

>> Hot Multi Cavity Other Riha Offer Plastic Products Customized Cylinder Shock Absorber

>> Jinmao Textile Machine High Speed High Precision Short Running In Long Life Spinning Machine TP3 JM1/2 EL3 gc 14/0 Series Ring Traveller

>> 55kw-6p Stable Quality Dimond Wire Saw Machine for Marble Quarry

>> Automatic Animal Feed Pellet Machine for Making Chicken Pig Feed

>> Ambulance Car Van Shape Customizable Promotional PU Foam Product Squeeze Anti Stress Ball for Novelty Toys Gifts

>> Automated Filter Tester PFE Meltblown Fabric Testing Machine ASTM F2299

>> Minimalist Design Folding 350W 36V 4-Wheel Electric Mobility Scooter for Disabled

>> Commercial Single Burner Gas Stove with Cast Iron Cooker Cap Home Appliance

>> Txk Winch Factory Manufacturer 5 Ton Low Headroom Hoist

>> Security Guard Tracking Watchman Clocking System Security Guard Patrol Tour System Touch Patrol System

>> Best Price CNC Gantry Machining Center GF-3025 Machining Center CNC Gantry Milling Machine

>> Metal Enamel Key Chain Round Circle Keyring Custom Motivational Keychain Key Ring Word Keychains

>> Big sales wool washing machine with CE

>> Wireless Bluetooth Magic Mouse Rechargeable Mac Laptop Mac Computer Pad Dedicated

>> 100W 200W 300W 500W Q Pulse Fiber Laser Cleaning Machine for Mould Mold Cleaning

>> High Quality Solar Panel Mounting Bracket Roll Forming Machine

>> Manufacture IQF Frozen Carrot Strip Factory in Qingdao China

>> Tilt & Turn windows Outside in matel dark gery color inside in Irish oak(RENOLIT Germany) big laminated glass window casement

>> byloo Portable Foldable Fishing Rod Carrier Multifunctional One-shoulder Fishing Rod Storage Bag Professional Sports Fishing Bag

>> long life and high quality dust collection filter manufacturer

>> 2022 NIBOSI Luxury Women Quartz Watches Ladies Creative Bracelet Wristwatches Female Clock Relogio Feminino Montre 2535

>> 2011 2014 Red C180 C220 C250 C350 Rear Tail Light for C Class W204 2049060203

>> High Quality Custom Coal Production Peat Fuel Briquette Extruder Machine

>> SHENGKE Decent Women SK Watch K0105L Business Style OL Handwatch Geometric Design Sliver Ultra Wristwatches

>> Factory Price Fried Raw Kurkure Cheetos Crunchy Snack Nik Nak Niknak Food Extruder Making Processing Machine Production Line Extrusion Processor Plant Equipment

>> Universal mill drill machine X6332C

>> Inclined Surface RAM Rotation Instrument Manufacturing Turret Milling Machine for Sale

>> Industrial Poultry Automatic Chicken 1023 Egg Incubator Hatcher Machine Egg Incubator Machine

>> high quality stainless steel material BBQ expanded metal mesh