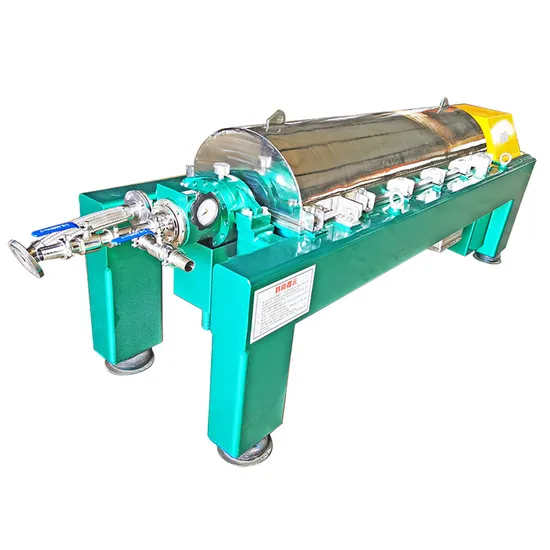

Plastic Wastewater Continuous Decanter Centrifuge 3phase Horizontal Decanter

Basic Info.

Model NO.

LW

Type

Centrifuge

Object

3 Phase

Separation Mode

Decanter

Operating Type

Continuous Type

Installation

Horizontal

Centrifuge Type

Horizontal Spiral Centrifuge

Distillation Equipment Type

Centrifuge Type

Extraction Tower Type

Turntable Tower

Pressure

Low Pressure

Condition

New

Working Mode

Continuous Flow

Maximum Solid Content

20%

Type of Separator

Three Phase Separating

Material of Contact Parts

SUS304

Solid Content

Not More Than 30%

Transport Package

Standard Export Package

Specification

3490*860*1200mm

Trademark

COBRO TECH

Origin

China

HS Code

84741000

Production Capacity

1000sets/Year

Packaging & Delivery

Package Size

2650.00cm * 1250.00cm * 1350.00cm

Package Gross Weight

1500.000kg

Product Description

Product Description Plastic wastewater continuous decanter centrifuge 3phase horizontal decanterCentrifuge decanter is a kind of high-efficiency centrifugal separation and sedimentation equipment with horizontal screw discharge and continuous operation. Decanter centrifuges can generally be divided into horizontal spiral filter centrifuges and horizontal spiral sedimentation centrifuges. Decanter centrifuges are suitable for dewatering sludge produced in the process of industrial and civil sewage treatment, and are also widely used in chemical, light industry, pharmaceutical, food, environmental protection and other industries.

Working principle of centrifuge separator

Drum and screw are working with higher speed at a certain differential rotation. Material is transported into spiral tube continuously , accelerated after the rotary drum, in under the action of centrifugal force field, the heavier solid deposit formed in the drum wall sediment layer.The feeding screw continuously pushes the solid phase of the deposit to the drum cone, and then out of the drain.The lighter liquid phase forms the inner liquid ring, which is continuously overflowed by the large end of the drum, and is discharged through the drain outlet.The machine operates at full speed, continuously feeding, separating, washing and discharging.It has the characteristics of compact structure, continuous operation, stable operation, strong adaptability, large production capacity and convenient maintenance.It is suitable for the suspension with solid phase particle size greater than 0.005mm and concentration range of 2-40%.Widely used in chemical industry, light industry, pharmaceutical, food, environmental protection and other industries.

Features of centrifuge separator

The machine can continuously feed, separate and unload at full speed. It has the characteristics of compact structure, continuous operation, stable operation, large production capacity, convenient maintenance and low energy consumption. It is suitable for separating suspensions with solid particle size greater than 0.005-10mm, concentration range of 2-40% and temperature less than 100°C.

Control System of centrifuge separator

Column-cone horizontal helical decanter centrifuge, conical column drum, inner push screw, cover, motor, differential, frequency converter and PLC control system, body seat, shock-absorbing pad, etc.

Application of centrifuge separator Plant and Chinese medicine extraction: honeysuckle extract, tea polyphenol extract, etc. Food and feed: dehydration of fish meal and fish meat, separation of fruit juice and pulp fiber, dehydration of soybean, wheat protein, xylitol, corn fiber, vegetable starch, etc. Mycelium separation of antibiotic fermentation broth. Separation of blood products. Separation of various animal oils, vegetable oils and mineral oils. Separation of lees. Separation of humic acid. Separation of dyes and pigments. Particle size classification of various particles. 10 Separation of various chemical materials. Municipal sewage and power plant sewage, printing and dyeing sewage, papermaking sewage and other industrial waste water. Product Parameters

| Model | Diameter (mm) | Length (mm) | Speed (r/mm) | Separation ratio | Output (m3/h) | Power(KW) | Weight(kg) | Dimension(mm) (L×W×H) |

| LW220×930 | 220 | 660 | 5000 | 2835 | 0.5~5 | 7.5 | 1200 | 2420×700X1010 |

| LW300×1200 | 300 | 1200 | 4000 | 2550 | 1~5 | 7.5~11 | 1500 | 2680×830×1280 |

| LW355×1600 | 355 | 1600 | 3800 | 2868 | 1~20 | 15~18.5 | 1850 | 3490×860×1200 |

| LW400×1200 3phase | 400 | 1200 | 3650 | 3000 | 1~5 | 15~18.5 | 2500 | 2990×960×1205 |

| LW400×1800 | 400 | 1800 | 3650 | 3000 | 2~25 | 15~22 | 2500 | 3890×1020×1205 |

| LW400×1800 3phase | 400 | 1800 | 3650 | 3000 | 2~10 | 15~22 | 2500 | 3890×1020×1205 |

| LW450×2000 | 450 | 2000 | 3450 | 3000 | 3~35 | 22~37 | 3000 | 4297×1080×1385 |

| LWS450×2000 3phase | 450 | 2000 | 3450 | 3000 | 3~35 | 22~37 | 3000 | 4297×1080×1385 |

| LW500×2000 | 500 | 2000 | 3000 | 2500 | 5~45 | 30~37 | 3800 | 4330×1140×1470 |

| LWS500×2000 3phase | 500 | 2000 | 3000 | 2500 | 5~45 | 30~37 | 3800 | 4330×1140×1470 |

| LW530×2280 | 530 | 2280 | 2900 | 2500 | 15~65 | 45~55 | 5000 | 4924×1170×1540 |

| LWS530×2280 3phase | 530 | 2280 | 2900 | 2500 | 15~65 | 45~55 | 5000 | 4924×1170×1540 |

| LW580X2500 | 580 | 2500 | 2780 | 2500 | 20~80 | 55~75 | 6500 | 5205×1270×1540 |

| LW650X2800 | 650 | 2800 | 2500 | 2270 | 20~110 | 75~90 | 7000 | 4924×1170×1540 |

| LW760X3040 | 760 | 3040 | 2250 | 2150 | 15~65 | 90~132 | 8500 | 4924×1170×1540 |

Certifications

Company Profile

FAQ

Other related products

Disc Centrifuge Separator Vibration Filter

>> China Factory Disposable Waterproof Coverall Industrial Full Body Overall Suit Chemical Resistant Coverall Jumpsuit

>> Automatic Hydraulic Uncoiler/Decoiler for Cold Roll Forming Machine with ISO9001/CE/SGS/Soncap

>> HP Graphite Electrode 350mm

>> peanut butter manufacturing process | Peanut Butter Making Machine

>> Harmless Treatment Equipment for Livestock and Poultry Wastes Compost Cover Compost Substrates Agricultural Equipment

>> Rubber Automatic Mixing Weighing Conveying System Vacuum Conveying System Pneumatic Conveying System/Pneumatic Transport System Vacuum Conveyor Feeding System

>> Different Type of Plug Safety Plug Leakage Protection Electrical Plug

>> BJJ kimono 2020 /custom embroidery patches bjj gi

>> F300 One Side Strong NdFeB Fishing Magnets with 500kgs/1100lbs Pull Force

>> Scandinavian High Value Floor Lamp Living Room Bedroom Lamp Designer Art Sofa Side Minimalist Light Luxury Standing Floor Lamp

>> 2024 CE Certified 3000W 6000W 12000W 20000W Wholesale Global Sources CNC Enclosed Laser Cutter for Metal

>> Automatic zinc alloy product cryogenic deburring machine Ultra Shot NS-120T

>> Manufacturer Alsafe Scuba Air Tank Sizes for Scuba Diving

>> Electric Versatile ATV 5000W 10000W off-Road Electric Scooter Electric Mountain Tank

>> Anti Radiation Fire Proof Large Faraday Bag Sets Anti RFID Anti Tracking Signal Stop Bag with Luminous Stripe

>> HDPE PE Water Supply Pipe Extrusion Machine

>> Air Conditioner Cleaning Set Mlo-230111

>> Luxurious Foot Massage SPA Pedicure Chair

>> Factory Direct Sale Multi-Functional Black Carbon Steel Large Outdoor Camping Wood Stove for Outdoor Cooking and Heating

>> High Quality Deburring Machine for Auto Motorcycle Furniture Medical Hardware

>> Cheap high quality horizontal sliding window prefabricated aluminum windows and doors

>> 16X Digital Zoom Cheap 4K Camera 44MP Built in Flash Light Auto Focus Mini Digital Camera

>> Princebend 6 Axis CNC Press Brake Controller Esa860 Bending Machine

>> Lb-4000 Asphalt Concrete Mixing Plant, Mixing Station Backyard Equipment

>> Dual Servo Torsion Axis CNC Bending Machine Torsion Bar CNC Press Brake From China Bending Machine

>> Shengya Qtj4-25 (QTJ4-26) Automatic Concrete Hollow Block Making Machine Simple Production Line

>> TUF-2000B New generation Digital Wall Mounted Clamp On Ultrasonic Water Flow Meter Flowmeter with Heat Meter TUF-2000B DN50-DN70

>> HC-M063 Hospital furniture lockable wooden medical Bedside Cabinet with dining board

>> Prima 80t1600mm Press Brake Bending Machine Esa-S630 6+1 Aixs with High Quality

>> Winter Thick Thick Tassel Jacquard Geometric Imitation Cashmere Yarn-Dyed Scarf