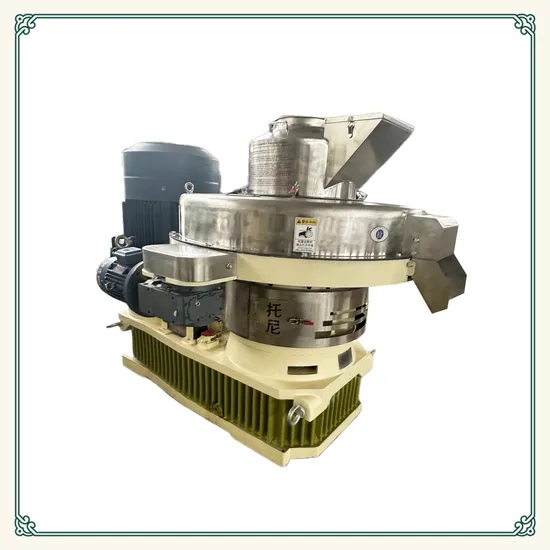

Tony Environmental and Big Gear CNC Biomass Pellet Mill

| US$42,000.00-48,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

TYJ760-III

Automatic Grade

Automatic

Controlling Mode

CNC

Energy Saving

Energy Saving

Certification

CE, ISO

Warranty

1 Year

Customized

Customized

Condition

New

Color

Multi Color

After-sales Service

All Working Life Service

Power

160kw

Capacity

2.5-3t/H

Pellets Diameter

6-10mm

Weight

9ton

Suitable Materials

Wood, Sawdust, Rice Husk, Biomass Waste and So on

Lubrication System

Automatic

Power Consumption

75%

Ideal Moisture

10-15%

Materials of Die and Roller

High Alloy Steel

Bearing

Hrb Brand

Installation

Manual/Video Chat/Engineer Guide

Transport Package

Iron Box

Specification

2564*1750*2150

Trademark

TONY

Origin

China

HS Code

847930000

Production Capacity

2.5-3.5t/H

Packaging & Delivery

Package Size

266.00cm * 185.00cm * 225.00cm

Package Gross Weight

9000.000kg

Product Description

Tony Environmental and Big Gear CNC Biomass Pellet MillIt is a newly wood pellet production machine, researched, designed and produced by ourselves. It's mainly used to produce biomass pellets from the materials kinds of wood, waste wood and straws, etc. such as woodchips(palm, pine white pine, mahogany, pinus sylvestris, rubber tree), bamboo shavings, rice hust, seeds shells, peanut shells, halm, pennisetum, wheat straw, corn stalk, cotton stalks, alfalfa grass, bagrass, palm fiber, waste paper, non-physical material.

Features of wood pellet production machine:

Self -lubrication system

A.Spindle automatic lubricatin system

B.Roller automatic lubricatin system :it can keep the pellet machine in maintenance for 24hours.

Output of pellet mill machine: Our machine can reach the expected output in our technical parameter.

Working Life of spare parts: Working life of our dies is 3000-4000 hours, much longer than others'.

Number of Our Ring Die holes: Our ring die has 5 rows of holes, much more than others'.

Driving Method of pellet machine: Our machine is drived by gear,not reduction box; Gear driving is helpful to increase the usage life of gear, so the maintenance rata of gear is much lower.

Forged Main Shaft: Our main shaft is forged, not casted. As well known, there is no air bubble in forging process, so it is hard to be broken.

Technical Pareameters:

| Model | Power(KW) | Capacity(T/H) | Size(MM) | Weight(Ton) |

| TYJ551-II | 90-110 | 1-2 | 2364*1550*1705 | 5.5 |

| TYJ551-III | 132 | 2-2.5 | 2364*1550*1705 | 5.5 |

| TYJ760-III | 160-180-200 | 2.5-3.5 | 2564*1750*2150 | 9 |

| TYJ860-III | 220-250 | 3-5 | 2664*1950*2150 | 13.5 |

High Technology Production Device:

High Quality Spare Parts:

Double-layers Ring Die

All kinds of pellet machine only have 1 die(ring die).Material: alloy, stainless steel Life time: 3000-4000hours1.The professional heat treatment processing technology can make its hardness above HRC62.2.Vertical Ring die, feeding vertically.3.Double-lay die, dual use. When one side is damaged, turn over and use the other side.4.The compression ratio can be custom made Rollers1.Number of rollers:2 pieces2.Die fixed, rollers running, materials centrifugal and evenly distributed around.3.Structure:roller shell and bearing4.Working life of rollers:1500-2000 hours Spindle1.Our main shaft is forged.2.no air insde the main shaft while being forged3.hard to be broken while high-speed running Motor1.Efficiency high overload capacity, low noise, small vibration

2.Reliable structure.

3.Rated Voltage 380V Rated Frequency 50HZ

4.400V 415V 420V 440V 690V 1140V and 60HZ ect.

5.Can also be made according to customers' requirements. Self-lubrication System1.Lubricating rollers to make the pellet press machine continuously run for 24 hours(using lubricating grease).

2.It also has the warning function when high pressure/temperature or low pressure/temperature appear.

Parameters of the pellets produced by TONY wood pellet production machine:calorific value: >3000~3500 kcal/kgdensity: >1.1~1.3t/m³moisture: <=10%combustion ratio: >=98%heat efficiency: >=81%ringelman emittance : <1discharged dust consistence: <=80mg/m³ash content: <=2%

Company Information:

Clean Workshop:

If you are interested in our wood pellet production machine,please send us inquiry freely. Before quotation we need to know:1. What's the capacity you plan to produce?

2. What's the raw material?

3. What's the size of the raw material?

4. What's the moisture content of your raw materials?

5. What's the final pellet size do you want?

>> modern aluminium garage door for dealers displayracks for house

>> Reliable DDP Door to Door Dropshipping From China to Nepal Shipping to Kathmandu

>> High Precision Small Mini Fiber Laser Cutting Machine for Sheet Metal Jewelry Glasses Machinery Equipment Lighting Watches Clocks Car Parts Craft Gifts

>> Discount Price Laptop Charger 90W 20V 4.5A Battery Power Adapter for Lenovo

>> Hydraulic Port Crane Grab Lifter Grab Bucket GB001

>> Modern Design Hurricane Impact Double Tinted Glass Balcony Aluminum Frame Sliding Window

>> China Logistics to Azerbaijan Freight for Truck by Land Transport From Urumqi to Baku

>> Wheel roller grinding and mixing machine for charcoal briquette production line

>> Large Indoor Decoration Project Pendant Lights Fixture Hotel Villa Modern LED Chandelier

>> Carbon Steel Pipe ERW Tube Mill Used on Pipe Factory

>> 5 Stage Home Water Purification and RO System

>> Plastic Crate Mould Injection Molding Equipment

>> 20FT ISO Tank for Lox/Lin/Lar T75 Based on ASME Standard

>> Budget SUV Ht PCR Tire Car Tyre Export Company with Quality Insurance 265/65r17

>> PP PE Flakes Recycling Washing Line

>> Fixtec Power Tools 4V Impact Screwdriver Rechargeable Battery Powered Cordless Electric Screwdrivers

>> Commercial Juice Extractor Machine Fruit Juice Making Machine Industrial Sugar Cane Pineapple Calamansi Orange Juice Extractor

>> Zero Defect Mylar Film Wrapping Machine for Sandwich Busbar

>> Hot Selling Patio Aluminum Furniture Set Corner Lounge Outdoor Garden Sectional Sofa

>> 180 degree Long type Grease Nipple for Lubricating

>> Luxury Trendy Summer Women′s Slippers Designer Slipper Luxury Top Slippers for Women Shoes

>> 1 Ton Crawler Small Micro Farm Garden Digger Hydraulic 800kg Cheapest Mini Excavator 1 2 Ton for Sale

>> Automatic Rotary type ice cream juice jelly water milk yogurt cup filling and sealing machine

>> For Mercedes-Benz W204 coupe change C63 AMG body kit

>> Bull Head Ice Cream Cone (Chocolate Flavor)

>> Fresh Natural White Galic Purple Garlic Red Garlic Normal White Galic

>> Residual Current /Vacuum Circuit Breaker/Miniature Circuit Breaker/Mini Circuit Breaker/ RCCB ELCB MCCB 6ka 10 Ka 12.5~125A Moulded Case Circuit Breaker

>> High quality Metal chain link mesh steel curtain ISO Certificate

>> Horizontal Metal lathe machine CW61100L CW61125L heavy manual lathe machine

>> 2020 New USB Car Negative Ion Air Purifier with Hepa Filter