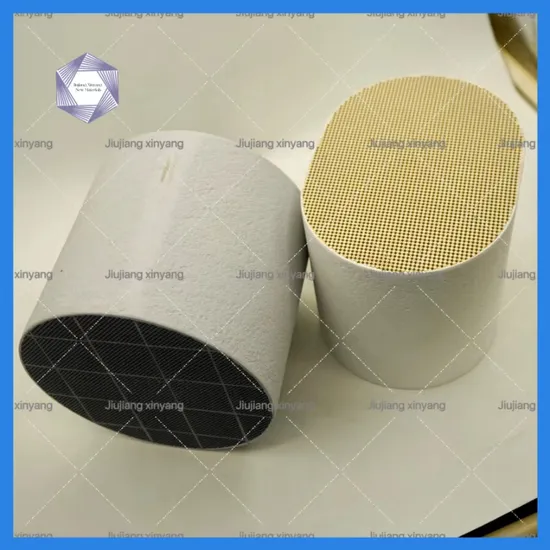

OEM Auto / Truck Parts Silicon Carbide Based Honeycomb Ceramic Diesel Particulate Filter for Catalyst Converter DPF

| US$26.00-180.00 | 1 Piece (MOQ) |

Basic Info.

Body Material

Cordierite Stone

Discharge Standard

Euro IV

Certification

ISO9001

Noise Source

The Noise of Engine

The Noise of Engine

The Combustion Noise

Automobile Chassis Noise

Tire Noise

Component

Catalytic Converter

Main Market

Southeast Asia

Transport Package

Cardboard Box/Wooden Pallet

Specification

330 * 305mm, 240 * 305mm, and 144 * 152.4mm, etc

Trademark

JJXY

Origin

China

HS Code

84213990

Production Capacity

100000

Product Description

DPF carriers are mainly made of ceramic and metal based materials.

Ceramic based DPF carrier materials include cordierite, silicon carbide, mullite, zirconia, etc. These materials have good high-temperature stability, chemical stability, and mechanical strength, and can effectively capture and store particulate matter.

Metal based DPF carrier materials include sintered metal, foam metal, metal wire mesh, etc. These materials have a high specific surface area and good thermal conductivity, which is beneficial for the capture and regeneration of particulate matter.

At present, the most commonly used filter materials are cordierite and silicon carbide. These two materials are widely used due to their excellent performance, among which cordierite has a certain advantage in the market due to its lower cost and good filtration effect. Silicon carbide, on the other hand, is more suitable in some special application scenarios due to its higher high temperature resistance and chemical stability

Diesel particulate filter based on cordierite

The advantages of cordierite (DPF) mainly include its suitability for purifying diesel exhaust particulate matter (PM), good oil adaptability, and relatively low cost.

Suitable for diesel engine exhaust particulate matter purification: The cordierite DPF, as a special structure honeycomb ceramic filter with wall flow, is mainly used in diesel engine exhaust particulate matter (PM) purification devices. It utilizes the pores on the wall of the wall flow filter to intercept solid particles in the diesel engine exhaust, thereby purifying the diesel engine exhaust.Product Parameters

| project | |||||

| Thermal shock resistance | Keep at 500 ºC for 30 minutes, quickly remove and cool at room temperature for 30 minutes. Repeat this process continuously for 3 times | muffle furnace | |||

| compressive strength | A-axis | >=5Mpa | Compression strength machine | ||

| B-axis | >=2Mpa | ||||

| Thermal expansion coefficient (room temperature -800 ºC) | <=1.2*10-6/ºC | Thermal expansion coefficient meter | |||

| Water absorption rate | 38% | Electronic scale | |||

| Content of main crystal phase in cordierite | >=90% | XRD | |||

| chemical composition | AL203 | 35.4±1.5 | |||

| Mg0 | 13.5±1.5 | ||||

| Si02 | 49.7±1.5 | ||||

>> 831149 Leyland Fuel Pump

>> Wholeprice Selling Gym Fitness Adjustable Atented Acupressure Back Massage Inversion Table

>> Bestlink Pneumatic Mobile Rock Driller for Horizontal

>> Office Furniture Metal Cabinet Tall Storage Filing Cabinet

>> Cycjet Lf30f Laser Marking Machine for White PVC Pipes

>> Aluminium Golden Finish Floor Number Sign for Apartment Home Office

>> Gmu500 CNC Milling Machine Center

>> Cardboard Box Shredder Paper Waste Shredder/ Plastic Waste Crushing Machine

>> Va-40nc Bandsaw Machine

>> GE IS215UCVEM06A Modular

>> Auto Parts Automotive Wheel Locking Hub Bolts Lug Stud for Auto Motor

>> China CNC Lathe Machine High Precision Slant Bed CNC Lathe Torno CNC Lathe Machine Price (SL-07)

>> Jez Car Body Shop Cleaning Machine Car Hood Paint Removal

>> China Top Brand 45ton Srsc4545h4 New Reach Stacker Prices

>> popular diamond shape Expanded Metal Wire Mesh For decorative

>> Vacuum Air Pot

>> Dark White Kidney Beans Long Shape Kidney Beans

>> High-Fill Maternity Pillow Cotton Crystal Velvet Pregnancy U-Shape Pillow Back Support & Nursing Aid for Side Sleep and Nursing

>> Cattle Stake Truck Trailer with Tandem Axle (SWT-CTT95)

>> Mining ore Gold Copper Fluorite flotation cell machine

>> Popular Portable Clothes Horse Rack With Cover

>> 9600 Highlight Clear Quality Cheap Price Clear Coat Base Coat for Car Paint

>> Drilling Machine Mini Manual Drilling Cheap Pricez5180 Small Vertical Drilling Machine

>> Boat Windshield Glass/Windscreen Glass/Boat Tempered Glass/Yacht Glass

>> Car auto automatic tail gate lift power tailgate for Nissan Patrol Y62 electric tailgate 2012-2021

>> Hot Selling Natural Fiber Wall Covering Silk Plaster Liquid Wallpaper Wall Coating

>> Direct Factory Custom Printed Laminated 50g 100g 250g 500g Potato Chips Packaging Bag for Potato Chips Corn Chips

>> factory direct sale good price auto body parts accessories BUICK Lacrosse 2009-2012 steel car engine hood 20794199

>> High Quality MC501 CDR2 Esd Nylon rod

>> 1000L Explosive-Proof Motor Kneading Mixer Sigma Mixer with Extruder