Rg400SD-Precision Surface Grinding Machine with Rotary Table

| US$10,000.00-40,000.00 | 1 set (MOQ) |

Basic Info.

Model NO.

RG400SD

Type

Surface Grinding Machine

Processing Object

Metal, Ceramics Flat Surface

Abrasives

Grinding Wheel

Controlling Mode

PLC Control

Automatic Grade

Automatic

Cylindrical Grinder Type

Metal, Ceramics Flat Surface

Precision

High Precision

Certification

CE, ISO 9001

Condition

New

Table Size

φ400mm

Floor Space

3300*2600mm

Total Power

9kw

Spindle Speed

1440rpm

Vertical Motor

Siemens Servo Motor

Cross Feed Motor

Siemens Servo Motor

PLC Brand

Siemens PLC

Spindle Motor

ABB/Siemens

Spindle Bearing

NSK P4 Grade

Hydraulic Brand

Taiwan Brand

Main Electrics

Schneiders Electrics

Crossfeed and Vertical Screw

P4 Grade Ball Screw

Buttons

Stainless Steel Button

Signal Lamp

LED Tri-Color Light

Chuck

Electric Magnetic Chuck(Fine Pole)

Transport Package

Wooden Case

Specification

3300*2250*2200mm

Trademark

ZODE

Origin

China

HS Code

8460191000

Production Capacity

100/Year

Product Description

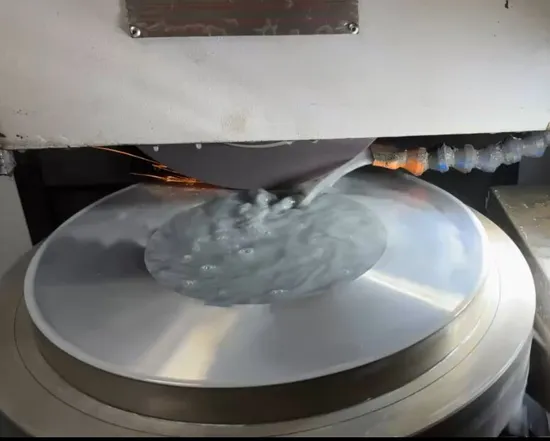

1. Pictures

2. Parameters

| Parameters | Unit | RG400SD | |

| Working Surface of Table | mm | Φ400 | |

| Max.Cross Travel | mm | 250 | |

| Distance Between Table Surface and Spindle Center | mm | 400 | |

| Max.Table Load | kgs | 200 | |

| Table Speed | rpm | 10~150 | |

| Cross feed Handwheel | 1gard | mm | 0.02 |

| 1 rev | 5 | ||

| Automatic Crossfeed of Saddle | mm | 0.01~12 | |

| Automatic Crossfeed Rate | mm/min | 10~800 | |

| Power Cross Feed | mm/min | 1500 | |

| Grinding Wheel Dimensions | mm | 355×40×127 | |

| Spindle Speed | 50HZ | rpm | 1450 |

| 60HZ | 1740 | ||

| Vertical Handwheel | 1gard | mm | 0.001 |

| 1 rev | 0.1 | ||

| Automatic Down Feed Rate | mm | 0.001~0.1 | |

| Power Head Increment | mm/min | 210 | |

| Spindle Motor | kw | 4 | |

| Vertical servo Motor | w | 1000 | |

| Coolant Motor | w | 90 | |

| Crossfeed servo Motor | w | 400 | |

| Floor Space | mm | 2600×2500 | |

| Packing Dimensions | mm | 2150×1940×2195 | |

| Net Weight | kgs | 2100 | |

| Gross Weight | kgs | 2300 | |

3. Standard Accessories

| 1 | Grinding wheel | 2 | Wheel flange |

| 3 | Wheel balancing base | 4 | Wheel balancing arbor |

| 5 | Extractor | 6 | Diamond dresser |

| 7 | Leveling pad | 8 | Anchor bolt |

| 9 | Tool box with tools | 10 | Electric chuck |

4. Feature SD stands for high configuration program control, three-axis automatic, longitudinal hydraulic drive,cross feed and vertical axes are driven by servo motors, and equipped with touch screen to set parameters(Automatic down feed, the minimum down feed is 0.001mm, and has the functions of rough grinding, fine grinding, automatic lifting and spark out grinding).

[hydraulic automatic longitudinal feed, electronic automatic cross feed(use servo motor),incremental auto down feed (use servo motor)]

1. Well designed cast iron structure provides excellent dampening

2. Flange mount spindle cartridge for superior side grinding rigidity

3. Grinding spindle features low-maintenance preloaded high precision angular ball bearings(NSK P4 grade)

4. "V" and flat type guide way which precision hand scrapped turcite saddle ways for smooth and long lasting performance

5. Table guideways are hardened, ground and counter-laminated with PTFE to ensure high wear-resistance

6. Centralized automatic lubrication system ,supplies oil to guide-ways and lead-screws as the machine operates. This system

ensures all the critical components are lubricated with the right amount of oil at all times

7. Separate hydraulic tank prevents heat and vibrations from being transferred to the machine

8. Electric components and functional modules are well arranged and packed in the electric cabinet, making maintenance and

trouble-shooting easily accessible

9. Safety 24V control circuit power

Application:

Applicable to all kinds of processing machinery, auto parts, fixture, magnetic steel, mould parts processing industry.

The machine tool can be made of grinding steel, iron, ceramics and non-ferrous metal parts.

Main Configuration of Grinding Machine

1. Spindle motor: Use ABB brand which from Sweden.

2. Spindle bearing: Use NSK brand P4 grade precision ball bearing which from Japan.

3. Cross screw: Use P5 grade precision ball screw.

4. Main electrical components: Use S C H N E I D E R brand.

5. Main hydraulic components: Use brand from TAIWAN.

6. Cross feed and down feed servo motor: Use SIEMENS brand.

5. Company & Factory

Nantong ZODE Machinery Manufacturing Co., Ltd. is a manufacturer engaged in the research and development, production, sales and service of CNC grinding machine equipment. The company adheres to the advanced production technology and technology in cooperation with Germany, and is committed to building a domestic high-quality grinding machine manufacturer. The company has an excellent R&D team, which serves precision grinding and can provide low-cost and high-efficiency solutions according to the actual grinding requirements of customers.

ZODE Machinery has a huge distribution channel, and its products are sold all over the world. With "quality is the foundation, service is the foundation", it has won the trust and cooperation of global customers.

In the future,ZODE people will continue to devote themselves to professional grinding solution providers and work together with partners to meet the ever-changing new challenges.

6. Delivery Picture

7. FAQ

Q: Are you trading company or manufacture?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 10~20 days if the goods are in stock.Or it is 30~60 days if the goods aer not in stock,according to your quantity.

Q: Do you provide samples?is it free or extra?

A: Yes,we could offer the sample,but need extra cost.

Q: What is your terms or payment?

A: 30% T/T in advance,balance before shippment.

>> Car Universal Exhaust Three-Way Catalyst Catalytic Converter DPF for Sale

>> 1-3cm, 3-5cm, 5-8cm, 8-15cm Organic Pine Bark Wood Chip Mulch

>> Car Mats Vulcanizing Press Machine / Automatic Car Mat Making Machine

>> New Arrvial Backless Backless Camisole Mini Dress for Women

>> 135200Q010 - Timing Chain Kit Gear OE Number for TOYOTA AutoParts Camshaft Adjuster VT1064

>> Wear Resistant Color UHMWPE Sheet/UHMWPE Board PE Board

>> Portable Rotary Hydraulic Water Well Borehole Core Drilling Machine (XY-200)

>> New Aluminium Alloy Mechanical Dock Seals Automatic Industrial Loading Cargo Dock Shelter for Truck Container

>> Eco-Friendly Honeycomb Core Production Line with Starch and PVA

>> Cheap Price Luxury Eco-Friendly Indoor Washable Bathroom Room Coral Hotel Slippers

>> Top 10 Seller Ball Type Independent Assembly Precision Ball Die Set Holder Guide Post

>> E- Commerce Ebay Amazon Hot Sell Product No Install Ultrafiltration UF Reverse Osomosis RO Water Filter Faucet Water Filter Tap Water Filter Filtro De Agua

>> OEM/ODM Pet Wipes Manufacturers Safe Pet Eye Ear Paw Wipes Cat Dog Wipes for Organic

>> 139-21308/140-6603V Bearing Textile Machine Weaving Loom Parts

>> Wholesale Luxury Shopping Packaging Packing Gift Box Bags with Custom Printed Logo Kraft Paper Bag with Handle for Jewelry Coffee Tea Cosmetic Makeup

>> Agricultural Machinery for Soil Preparation Reversible Plow

>> 20W UL TUV CCC CE Dimmable Constant Current LED Lighting Power Supply for Street Light

>> A1 2-Inch IPS Screen Cartoon Dual Camera 20MP HD Digital Camera - Pink Sheep

>> Banbury Kneader Powder Automatic Weighing Equipment

>> Oxford Cute Style Boy Bag for School Students Stationery Gift

>> Hot Sale Low and Medium Pressure Boilers Seamless Steel Tube Steel Structure Fluid Conveying API 5L ASTM A106 A53 Oil and Gas Petroleum Cracking Seamless Pipe

>> Super Mini 4K HD Mini Smart Micro 1+16GB Dual WiFi 2.4G/5g Android Projector Mobile Portable Home D019 DLP Android Projector

>> Black Science and Technology Without Sharpening Pencils Without Ink Students Eternal Positive Posture Pencil

>> tay buy sl fishing rod collapible fish 2.4/2.7/3.0/3.3/3.6/3.9/4.2m Ultra Light wholesale fishing tackle pen rod for fish byloo

>> Automatic Cultural Pencil Cigarette Duplex Board Paper Making Machine with Good Service

>> Custom Kayak Safety Adults Life Jacket for Swimming

>> Kawaii Stuffed Keychain Toy for Promotional Gift

>> Large Production Capacity 1000-1200kg/H Poultry Pellet Machine for Sale

>> Electro Hydraulic Orange Peel Grab (Stone Scrap Rubbish)

>> Nylon Cable Tie Mold Plastic Injection Molding Machine