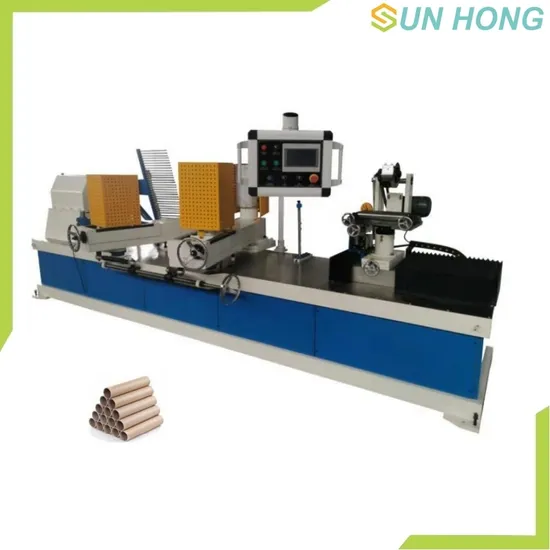

Packing Tissue Paper Core Tube Full Auto Spiral Rolling Making Machine

| US$800.00-3,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

Sun Hong

Paper Core Usage

Paintings Packaging, Instrument Package, Industry

Tube Machine Type

Bending Machine

Gumming Type

Double Side

Layers of Roll Paper

9 - 16

Reelpipe Speed

6 - 12m/minute

Wall Thickness of Paper Tube

5 - 10mm

Certification

CE, ISO

Condition

New

After-sales Service

Warranty

Inner Diameter of Tube

30-200 mm

Transport Package

Wooden Case

Specification

Make to order

Trademark

Sun Hong

Origin

China

Product Description

Paper Tube Making MachineFinal product: Cylindrical paper tube Raw material:Bobbin paper, kraft paper, white glue

Technical Parameter

| Inner diameter | ¢35mm-¢200mm |

| Thickness | 2-20mm(It varies according to the number of dense layers and the thickness of the paper) |

| Production speed | 0-20m/min(The speed is different due to the problem of paper tube specification and paper quality) |

| Cutting length | 500mm-4000mm |

| Main motor power | 15Kw |

| Working air pressure | 0.6Mpa |

| Fixed length mode | Infrared / encoder |

| Cutting motor | 0.75Kw |

| Gluing system | GT type |

| Paper holder | SZ type |

| Operator | 2-3 persons |

Main Function

A. Microcomputer length setting and accurate cutting length are adopted: the touch screen is convenient to adjust the data.

B. It adopts man-machine interface, special operating system and hanging operation panel, which makes the operation easier.

C. The paper strip tension control cutting system consists of an air pressure system, and the air cylinder compresses the paper strip, and its tightness can be adjusted at will.

D. 30 pieces of paper for gluing, including gluing box and pneumatic tension control, can be glued on both sides or on one side according to the strength requirements of the paper tube.

E. Mechanical paper feeding increases efficiency, reduces production personnel and reduces production costs.

F. The flange shaft is designed to be retractable, and the inner diameter of the paper tube can be fine tuned with the taper mandrel.

G. The transmission adopts frequency conversion speed regulation motor to adapt to the production of paper tubes with different requirements.

H. When the inner paper breaks, it can automatically alarm and stop the machine, so as to avoid sticking the mandrel with white glue.

I. The paper tube cutting part is controlled by the moving servo motor, which can track the production speed of the paper tube to achieve synchronization.

J. The paper pipe is cut by high-speed saw.

>> 1000L Powder Coating Mixing Machine Container Mixer

>> Factory Direct Farm Watering Agricultural Pesticide Stainless Steel Knapsack Sprayer

>> trend design aluminum frame double glazed sliding door interior kitchen sliding door

>> High Quality Wholesale Disposable Portable Bamboo Kids Tableware With Low MOQ

>> Factory Customizes Various Sizes Stainless Steel Aluminum Door Mortise Lock Body

>> Pnshar Paper Digital Thickness Testing Meter

>> China Factory New Car Tire Top 10 Chinese Tire Brand100% Warranty 265/75r16 31X10.50r15 245/75r16

>> High Output ABS/HIPS Plastic Sheet Making Machine/Single-Screw Extruder/Plastic Extrusion Machine/Plastic Machinery/Product Line

>> Life Size Outdoor Decorative Carved Stone Statue Carving Sculpture

>> Flat Webbing Sling CE Certified with Protect Eye

>> High quality gas lift cylinders gas strut for Honda Civic SR4 1992- 74820SR4J01

>> Three-Way Catalytic Converter with Honeycomb Ceramic Substrate Coatd with Catalyst to Control Emissions From Positive Ignition Engines

>> Wholesale Quantity Supplier of Modern Design Fashion Style Unisex Genuine Leather Mobile Cover

>> Pcp Paintball Hunting Pre Charged Water Cooler Not Hasten Air Hand Pcp Pump with Moisture Trap

>> CNC Vertical Lathe Machine Price Vtc70 Vertical CNC Lathe Vertical Lathe Casting

>> Plastic Injection Large Logistic Heavy Duty Customized Stardard Rackable HDPE Pallet Mould

>> Medical Stainless Steel Veterinary Injection Needle for Animal Use Needle

>> Z3080 Hydraulic Vertical Universal Automatic Manual Metal Radial Arm Drilling Machine

>> Industrial CNC Laser Equipment Metal Tube Pipe Fiber Laser Cutting Tube Machine Metal Tube Laser Cutter Tube Laser Cutting Machine

>> Hot Sale 1.5/2/2.5 Inches Fire Hose Coupling Set

>> Seamless Underwear Cotton Brassiere Half Molded 3/4 Seamless Sexy Bra Foam Cup

>> Tqs CNC H-612ks Six Side/6-Side Drilling Machine for Wood Work

>> OEM Custom ANSI RF 304L Stainless Steel Forged Weld Neck Flange Used for Customized Flange Plates of Various Specifications for Mechanical Parts

>> 93L Argon Cylinder Oxygen Cylinders Air Gas Cylinder Empty Seamless Nitrogen Cylinder

>> Taijia portable skid resistance tester Pendulum Friction Coefficient Tester Road friction coefficient tester

>> Spare Parts Car for GMC Savana Sliding Doors Car Modification Automatic Middle Door

>> Shd Fully Hydraulic Horizontal Grinder Wood Chipping Machine in Biomass Fuel Industrial

>> Knight Dinosaur/Amusement Equipment/Fun Dinosaurs/Outdoor Playground Equipment

>> Safe TCP/IP Network RFID How to Reset Fingerprint Time Attendance for Office Employee

>> Pta-8 Automatic Carton Box Printer Die Cutter Slotter Flexo Printing Slotting Machine