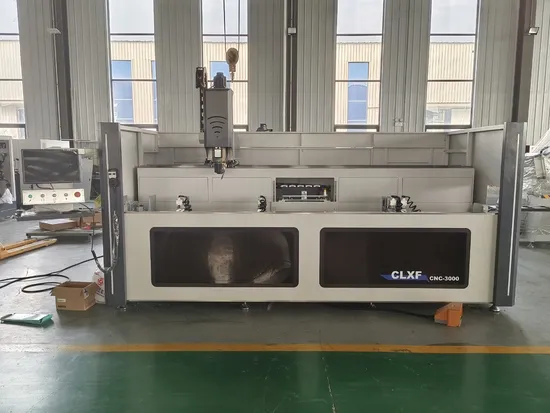

Window Drilling Equipment Fully Automatic Aluminum Profile High-Speed CNC Machining Center

| US$12,500.00-18,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

CLXF-CNC-3000

Condition

New

Certification

ISO

Automatic Grade

Automatic

CNC or Not

CNC

Voltage

380V

Total Power

7.2kw

Spindle Power

5.5kw

Spindle Speed

18000rpm

Working Air Pressure

0.5~0.8MPa

X-Axis Lateral Travel

3, 000mm

Y-Axis Longitudinal Travel

400mm

Z-Axis Vertical Travel

300mm

X-Axis Feed Rate

0~97m/Min

Y-Axis Feed Rate

0~30m/Min

Z-Axis Feed Rate

0~30m/Min

Number of Fixtures

6

Processing Range

140*140*3, 000mm

Processing Accuracy

±0.1mm

Dimensions

4, 300*2, 200*2, 000mm

Transport Package

Normally as The Export Standard Packaging or as Yo

Specification

Approximately 3, 000kg

Trademark

Chengjiang Machinery

Origin

Dezhou, Shandong

Production Capacity

100sets/Yea

Packaging & Delivery

Package Size

430.00cm * 220.00cm * 200.00cm

Package Gross Weight

3000.000kg

Product Description

Product Description1.Suitable for processing round holes, slots, lock holes, irregular holes in aluminum-plastic profiles, as well as milling, chamfering, and flat engraving of aluminum profiles. Automatic tool change, standard with a 6-position tool magazine for simpler processing.

No skilled worker required, operates online with software, automatic processing via scanning.

2.The worktable can be flipped, allowing for milling of three faces in one clamping operation.

3.Equipped with a standard graphics library for direct import of graphics to generate machining programs.

4.5.5kW Shenyi spindle motor, high torque, processing efficiency twice that of a regular drilling and milling machine.

5.Unique chip removal design, equipped with a bottom chip tray for a cleaner work environment.

6.Features a closed protective cover with automatic lifting, ensuring high safety performance.

7.Standard guide screw automatic lubrication device to extend the machine's lifespan.

8.Standard automatic maintenance reminder function to proactively address equipment issues and improve equipment utilization.

Detailed Photos

Product Parameters

| Input power supply: | 380V/50Hz |

| Total power: | 7.2kW |

| Spindle power: | 5.5kW |

| Spindle speed: | 18,000rpm |

| Working air pressure: | 0.5~0.8MPa |

| X-axis lateral travel: | 3,000mm |

| Y-axis longitudinal travel: | 400mm |

| Z-axis vertical travel: | 300mm |

| X-axis feed rate: | 0~97m/min |

| Y-axis feed rate: | 0~30m/min |

| Z-axis feed rate: | 0~30m/min |

| Number of fixtures: | 6 |

| Processing range: | 140×140×3,000mm |

| Surface roughness of cutting surface: | Ra12.5μm |

| Dimensions: | 4,300×2,200×2,000mm |

| Weight: | Approximately 3,000kg |

Company Profile

Shandong Chengjiang CNC Technology Co., Ltd is a high-end intelligent equipment manufacturing company that integrates research, production, and sales. We specialize in the research, development, manufacturing, and sales of intelligent industrial aluminum processing equipment, aluminum door and window equipment, aluminum curtain wall equipment, and plastic door and window equipment. Our outstanding research and development team and professional technical staff have laid a solid foundation to ensure the production of high-quality equipment. Chengjiang is dedicated to creating the most advanced door, window, and curtain wall processing equipment in China.

Our Advantages

Shandong Chengjiang CNC Technology Co., Ltd. is a door and window processing equipment company integrating industry and trade. Has the following advantages:

1. It has a casting workshop and an assembly workshop and can accept product customization.

Our company's equipment processing has a complete production line, from the processing of raw materials to the polishing, casting and painting of parts, all are carried out in the foundry workshop. After the parts are processed, they are transported to the assembly workshop for assembly and debugging. We have many years of experience in door and window equipment processing. Our company can accept customization requirements with different technical conditions and can customize production according to customer needs, including equipment length, equipment parameters, equipment color, etc.

2. Reduce costs, increase efficiency, and control quality.

The integration of industry and trade can integrate production and sales links, optimize the supply chain, reduce costs, and improve efficiency. Since the production and sales links are within the same company, product quality can be better controlled to ensure that products meet standards.

3. Professional technical R&D team with multiple patents.

The company has established a professional technical R&D team of more than 10 people, specializing in product R&D and improvement, and has multiple invention patents and its own intellectual property rights. And the technical personnel responsible for processing and assembly all have more than 10 years of work experience and strictly control product quality.

After Sales Service

Pre-sale service

Free contact for the most suitable machine

Free professional design for each customer especially. After sale service 24 hours technical support by phone, email or skype

1years warranty period

Our senior engineer is available to travel aboard, help the installation, maintenance and training staff.

FAQ

1.Are your company a trading one or a factory?

Factory + trade (integration), 14 years' focusing on Upvc,Aluminum Window and Doors Equipment and curtain wall equipment.

2.After an order is placed, when to deliver?

Generally about 15 days, If we have inventory, we can arrange shipment within 5 days.

Please be aware that our production lead times depend on specific items and item quantities.

3.What about the warranty with after - sales services?

12 months warranty. Besides,we can help you to solve your problem freely;

After the warranty,the professional after-sale service team will provide perfect technical support,and help customers solve problems ,encountered while using our products.Handles guest problems and complaints in a professional and timely.

4.What about the services and product' quality?

Each machine must be carried out 100% quality examination and test before shipment.

And all machines meet ISO and CE certification.

5. We don't know the machine operation, what should we do?

We can send engineer to your place, or we provide video training to show you how to install & operate, let engineer help you online.

>> Bordadora T-Shirt Beads Single Head Computerized Embroidery Machine Prices

>> Qingdao Haocheng Polyvinyl Butyral PVB Resin for Film

>> Low-cost EN12830 resuable temperature humidity datalogger with automated PDF reports TempUsb S3

>> 48V 200ah 100ah Lithium Battery Packs Solar Generator UPS Lithium Ion Battery

>> 52cc Mini Gasoline/Petrol Power Rotary Weeder Tillers for Farm Agricultural Ploughing Machine Cultivator

>> Wholesale Price Holiday Time Xmas Plush Ceramic Plastic Resin Metal Glass Wooden Polyresin OEM Personalized Custom Hanging Christmas Tree Decoration Factory

>> Slitting Circular Blade for Corrugated Cardboard Cutting

>> Premium Polyethylene PE 1000 Rod - Plastic Yellow UHMWPE/ HDPE Rods Perfect for Engineering, Crafting, and Home Improvements Strong & Versatile

>> Fancy solid wood door models interior door designs in Pakistan

>> Wall Tile Made in China for Bathroom and Kitchen (300X600mm)

>> customized perforated sheet metal mesh

>> Factory Handmade Realistic Good Quality Fiberglass Large Tiger Sculpture

>> 5 Axis CNC Bridge Saw Machine in America UK UAE

>> Medical Use Disposable Isolation Gown with High Quality

>> Zhongyuntech Zc-600h Automatic Cutting Machine for Double/Single Wall PVC Corrugated Pipe

>> Cre U1 4K Home Cinema Projector LED LCD Video Outdoor Smart Projector

>> HC-R019 Animal Clinic Equipment Medical Device Stainless Steel Veterinary Treatment Table

>> Hot Sale Poultry Egg Incuborts Price Automatic Egg Turning 3168 Eggs

>> LPG Filling Gas Cylinder Weight Scale for LPG Station

>> Double Shaft Customizable Shredder for Waste Carpet Fabric Textile Cotton Wool Clothing Wood Cardboard

>> High Speed Hot Sale CD DVD Copier CD DVD Duplicator Machine

>> Logistics Service Best Shipping Agent Service Air Cargo Air/Ocean/Sea Freight Forwarder From Shenzhen/Shanghai/Xiamen China to Chennai Nhava Sheva Shiping Agent

>> Water Supply Plastic Tubes Smooth Inner Wall PE Series Pipes for Sewage and Drainage Systems

>> F20 1 SERIES Hood Release Lever Handle 5123 7309 606

>> Layer Cage System for Chicken Battery Chicken Cage Hens Egg Cage for Sale

>> Big Wheel Vertical CNC Lathe Machine Wrc30V

>> Fashion Down Jacket Duck Pillow Down Industrial Filling Machine

>> Shopping Splicing Screen Wall Mount Big Did LCD Screen Board Price Advertising Display Controller Digital Signage Video Wall Screen

>> 100 Ton Leantall Bottle Embryo Injection Molding Machine Electric

>> 3 mm Fleece Plush Minky for Baby Blanket Toys