Fused Silica Grains Flour for Ceramic Shell Primary Slurry of Investment Casting

| US$500.00-750.00 | 1 Ton (MOQ) |

Basic Info.

Model NO.

30/50 50/100, 120mesh, 200mesh, 325mesh

Type

Fused Silica Sand and Powder

Sio2

>99.85%

Fe2o3

<0.007%

Al2O3 of Grains

<0.02%

Al2O3 of Powder

<0.12%

K2o+Na2o

<0.006%

Quartz Sio2

<0.1%

Cristabolite

<0.1%

Amorphous Matter

>99%

Transport Package

Paper Bag, Plastic Bag, Jumbo Bag, Pallet

Specification

Grade B

Trademark

Chemsize

Origin

China Lianyungang

HS Code

32074000

Production Capacity

10000mt/Year

Packaging & Delivery

Package Size

110.00cm * 110.00cm * 100.00cm

Package Gross Weight

1003.000kg

Product Description

We're fused silica sand and powder manufacturer: Best Severice and Quality!!!

Fused Silica Plastic Woven Bag of 25kg Net each,Then on Pallet:

Product Description Fused Silica sand&powder Specifications:

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750ºC | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

2. | Chemical Properties | ||

| 2.1 | SiO2 | >99.9% | |

| 2.2 | Al2O3 | <100ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <30ppm for grain | |

| 2.4 | CaO | <30ppm | |

| 2.5 | Na2O | <30ppm | |

| 2.6 | K2O | <30ppm | |

3. Particle Size Distribution

| Standard | |||||||

| 10-20 | 30-50 | 50-100 | -120 | -200 | -325 | ||

| Mesh | Microns | ||||||

| +8 | 2360 | <2 | |||||

| +12 | 1700 | 6-25 | |||||

| +16 | 1180 | 33-50 | |||||

| +20 | 850 | 25-45 | <1 | ||||

| +30 | 600 | 13 | 25-40 | ||||

| +40 | 425 | 32-45 | |||||

| +50 | 300 | 15-30 | <13 | ||||

| +70 | 212 | 30-60 | |||||

| +80 | 180 | 0-11 | <1 | ||||

| +100 | 150 | 28-51 | <10 | <1 | |||

| +140 | 106 | 4-16 | 7-13 | <10 | |||

| +200 | 75 | <2 | 10-15 | <10 | <3 | ||

| +325 | 45 | 14-20 | 15-30 | 4-11 | |||

| Pan | <3 | <2 | <1 | 45-55 | 70-80 | 86-97 | |

Fused silica production process

We strictly choosed the high purity silica sand (SiO2>99%) in local Donghai/Xinyi as our raw material. The melted silica sand becomes amorphous silicon dioxide glassy ingot after being fused at high temperature(2000-2300 ºC),and cooling. We further process the products into fused silica lump,sand and powder according to customer's requirements.

Fused silica Special Feature:

Fused Silica features extremely low coefficient of thermal expansion,consistent chemistry and carefully controlled particle size distribution.

Fused silica Applications:

Fused Silica are used in industry of thermal ceramic,refractory,investment casting,EMC,solar crucible,quartz marble,powder coating etc.

Fused silica other sizes are available as follows :

0-1mm 1-3mm 3-5mm,,0.2-0.5mm,0.1-0.5mm

-10mesh 10-20mesh, 30-50mesh, 50-100mesh,-100mesh,-150mesh,-270mesh,

30-60mesh,60-120mesh,40-70mesh,70-140mesh,100-200mesh,

120F, 200mesh, 325mesh, 400mesh ,600mesh , 800mesh, 1250mesh,etc...

The partice size can be produced as customer's special requirment.

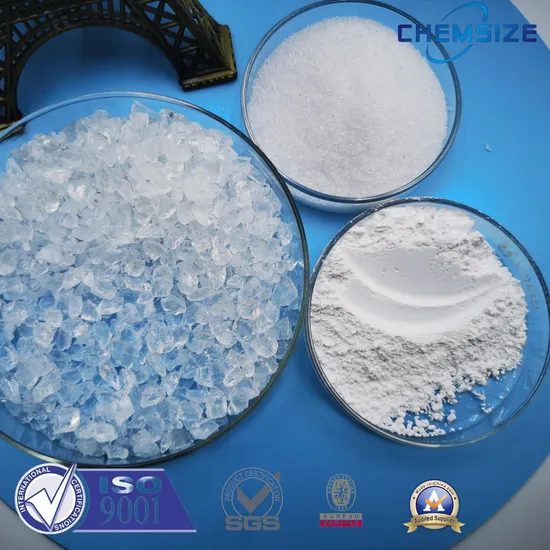

Fused Silica high clear Pictures:

Fused Silica Package and Delivery:

Paper bags

Fused Silica Plastic Woven Bag of 25kg Net each,Then on Pallet:

Fused silica Factory and Quality Control Pictures:

Fused silica making process

Fused Silica is made of high purity crystal silica from China Donghai-Xinyi by electrically fusing (fusing temperature 1800-2000ºC) to amorphous Silicon dioxide, then is specially engineered into lumps,cullet, ingots, sand,grain,granular and powder flour form designed for making PV fused silica crucible,thermal ceramic,refractory,EMC investment casting ceramic shell etc.

Fused Silica sand Appearance and Specifications:

1): It is forbidden to contain any unfused parts.

2): It is forbiden to have Foreign material, such as string, plastic line, carbon or wooden material, metal or other outside contaminants.

3): All color dots is forbidden except conditional black dots

4): It is not acceptable that black spot diameter is larger than 2mm.

5): Total black dots quantity should be less than 10 when opening the big bag equal or less than 10 dots per

square meters

FAQ:

Q1. Can I have a sample order for fused silica products?

A: Yes, we'd like to send samples free of charge by TNT/FEDEX/DHL. Mixed samples are acceptable.

Q2. What about the lead time?

A:It is 3-5 days for sending samples

It is usually within 15 days to delivery orders for quantity within 100mt,

Q3. Do you have any MOQ limit for fused silica sand order?

A: No.But the less the average cost higher.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 working days to arrive.

It depands on the distance by sea.7-40days.

Q5. How to process an order for fused silica powder Products?

A:

1).let us know your requirements or application.

2).We quote according to your requirements or our suggestions.

3).customer confirms the samples and pay deposit for formal order.

4).We arrange the production.

Q6. Is it OK to print my logo on packages?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q7: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less

than 0.2%.

Secondly,If it happened,we shall arrange to send new products to you and pay for all your lost.

Any question,kindly contact us please! We're fused silica sand and powder manufacturer/factory: Consistent Quality,Best Price and Severice!!!

Product Description Fused Silica sand&powder Specifications:

| 1. | Physical Properties | ||

| 1.1 | Composition | SiO2 | |

| 1.2 | Structure | Amorphous | |

| 1.3 | Colour | Transparent or white | |

| 1.4 | Melting Temperature | approx.1750ºC | |

| 1.5 | Specific Gravity | 2.21g/cm3 | |

| 1.6 | Hardness | 7 Mohs | |

| 1.7 | Thermal Expansion | 0.5*10-6 | |

2. | Chemical Properties | ||

| 2.1 | SiO2 | >99.9% | |

| 2.2 | Al2O3 | <100ppm | |

| The finer the power,the higher the Al2O3,as powder is produced by ball mill with Alumina ball. | |||

| 2.3 | Fe2O3 | <50ppm for grain | |

| 2.4 | CaO | <30ppm | |

| 2.5 | Na2O | <30ppm | |

| 2.6 | K2O | <30ppm | |

3. Particle Size Distribution

| Standard | |||||||

| 10-20 | 30-50 | 50-100 | -120 | -200 | -325 | ||

| Mesh | Microns | ||||||

| +8 | 2360 | <2 | |||||

| +12 | 1700 | 6-25 | |||||

| +16 | 1180 | 33-50 | |||||

| +20 | 850 | 25-45 | <1 | ||||

| +30 | 600 | 13 | 25-40 | ||||

| +40 | 425 | 32-45 | |||||

| +50 | 300 | 15-30 | <13 | ||||

| +70 | 212 | 30-60 | |||||

| +80 | 180 | 0-11 | <1 | ||||

| +100 | 150 | 28-51 | <10 | <1 | |||

| +140 | 106 | 4-16 | 7-13 | <10 | |||

| +200 | 75 | <2 | 10-15 | <10 | <3 | ||

| +325 | 45 | 14-20 | 15-30 | 4-11 | |||

| Pan | <3 | <2 | <1 | 45-55 | 70-80 | 86-97 | |

SGS Fused silica test Report:

Fused silica production process

Fused silica is high purity quartz sand that has been melted to form glass. High volume stability, low volumetric expansion and high purity make fused silica a very useful and versatile material for refractory applications, whether in aluminum launders or other highly cyclical applications.

We strictly choosed the high purity silica sand (SiO2>99%) in local Donghai/Xinyi as our raw material. The melted silica sand becomes amorphous silicon dioxide glassy ingot after being fused at high temperature(2000-2300 ºC),and cooling. We further process the products into fused silica lump,sand and powder according to customer's requirements.

Fused silica Special Feature:

Fused Silica features extremely low coefficient of thermal expansion,consistent chemistry and carefully controlled particle size distribution.

Fused silica Applications:

Fused Silica are used in industry of thermal ceramic,refractory,investment casting,EMC,solar crucible,quartz marble,powder coating etc.

Fused silica other sizes are available as follows :

0-1mm 1-3mm 3-5mm,,0.2-0.5mm,0.1-0.5mm

-10mesh 10-20mesh, 30-50mesh, 50-100mesh,-100mesh,-150mesh,-270mesh,

30-60mesh,60-120mesh,40-70mesh,70-140mesh,100-200mesh,

120F, 200mesh, 325mesh, 400mesh ,600mesh , 800mesh, 1250mesh,etc...

The partice size can be produced as customer's special requirment.

Fused Silica high clear Pictures:

Fused Silica Package and Delivery: paper bags,double layer jumbo bags

Fused Silica Plastic Woven Bag of 25kg Net each,Then on Pallet:

Fused silica Factory and Quality Control Pictures:

Fused silica making process

Fused Silica is made of high purity crystal silica from China Donghai-Xinyi by electrically fusing (fusing temperature 1800-2000ºC) to amorphous Silicon dioxide, then is specially engineered into lumps,cullet, ingots, sand,grain,granular and powder flour form designed for making PV fused silica crucible,thermal ceramic,refractory,EMC investment casting ceramic shell etc.

Fused Silica sand Appearance and Specifications:

1): It is forbidden to contain any unfused parts.

2): It is forbiden to have Foreign material, such as string, plastic line, carbon or wooden material, metal or other outside contaminants.

3): All color dots is forbidden except conditional black dots

4): It is not acceptable that black spot diameter is larger than 2mm.

5): Total black dots quantity should be less than 10 when opening the big bag equal or less than 10 dots per

square meters

FAQ:

Q1. Can I have a sample order for fused silica products?

A: Yes, we'd like to send samples free of charge by TNT/FEDEX/DHL. Mixed samples are acceptable.

Q2. What about the lead time?

A:It is 3-5 days for sending samples

It is usually within 15 days to delivery orders for quantity within 100mt,

Q3. Do you have any MOQ limit for fused silica sand order?

A: No.But the less the average cost higher.

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 working days to arrive.

It depands on the distance by sea.7-40days.

Q5. How to process an order for fused silica powder Products?

A:

1).let us know your requirements or application.

2).We quote according to your requirements or our suggestions.

3).customer confirms the samples and pay deposit for formal order.

4).We arrange the production.

Q6. Is it OK to print my logo on packages?

A: Yes. Please inform us formally before our production and confirm the design firstly based on our sample.

Q7: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less

than 0.2%.

Secondly,If it happened,we shall arrange to send new products to you and pay for all your lost.

Any question,kindly contact us please! ChemSize is manufacturer of fused silica which is produced by melting high purity natural silica sand(quartz sand) at 2200ºC 12 hours. In the fusing process, the crystalline phase of silica sand transforms into amorphous phase. After cooling, Fused silica ingot is made out with high purity amorphous silicon oxide. Fused silica ingot is separated into 5-10cm lumps Grade A, Grade B and Grade C according to the black point size.

Fused silica can be used to make crucibles that produce solar cells board in the photo-voltaic industry.

Fused silica is used to make rollers, castables, mortars, gunning mixtures and forming tools in the glass industry.

Fused silica is used to make technical ceramic in the thermal resistance industry.

Fused silica is used to make ceramic slurry in investment casting industry.

Fused silica is used to make Acidic acid refractory,Fused silica precast shapes,Fused silica big blocks and fused silica castables

>> Factory Direct Environmental Acacia Wood Cutting Board Chopping Board Set

>> Good Quality Working Load 120kg Tree Climber Spikes for Climbing Tree

>> Nmsafety PU Coated Level 5 Hppe Cut Resistant CE Safety Working Gloves

>> Csqx1000 for Core Diamond Drill Machine for Soil Exploration Projects Core Drilling Rig

>> Lpa-380TF 4 Zones FM USB Bluetooth Stereo High Power Amplifier OEM Factory

>> Factory Wholesale Mobile Phone LCD for Samsung Galaxy A10 A20 A30 A40 A50 A60 A70 A80 A90 A10s A20s A50s J5 J7 Prime J610 J327 J260 J330 J727 J120 Touch Screen

>> Taijia portable ultrasonic water flowmeter price Flange ultrasonic flowmeter

>> Industrial Round UFO Highbay Lighting 100 120 150 200 250 300 Watt Hanging Commercial Low LED High Bay Light for Warehouse Factory Workshop 170lm/W

>> Cbmmart Classic Kitchen Cabinet Solid Wood Cuisine Complete Free Kitchen Design

>> Full Automatic Stainless Steel Housing Tripod Turnstile

>> Original New Tto Printhead PCB Main Board Printer Videojet Domino

>> Best Quality China Manufacturer Miter Meat and Bone Cutting Saw Machine Power Food Sales Support

>> Mobile Construction Mixer Spider Hydraulic Concrete Spreader Placer Beton Concrete Placing Boom

>> Injection Machine for Taps with Liner

>> mixed phosphate P220 for injections

>> 10.4 Inch Embedded IP65 Waterproof Non-Touch Screen Industrial LCD Monitor Display USB VGA Industrial Monitor

>> Hooked Power Tools Single Phase Copper DC Motor Commutator

>> Life Saving Escape Emergency Hammer Seat Belt Cutter Window Glass Breaker Car Rescue Red Safety Hammer

>> 1000kVA Transformer Step up Transformer S11 Series Oil Immersed Transformer

>> Diamond Multi Tool Blades Segment for Marble Cutting

>> High Precision Variable Speed Mini-Lathe Tu2406 Tu2406 Precision Gear Head Lathe

>> High Quality Waterproof Nylon Spandex Lycra Fabric (Lf-014)

>> Ce Certificated Synthetic Graphite Powder Crusher with Complete Accessories

>> 5 gallon bottle inside outside washing machine 19 inner and outer brush bottle washing machine

>> 1200*2400mm Gypsum Board Plasterboard Interior Panel with Drywall Waterproof Sheets

>> Aeropak Aerosol 400ml Car Cold Galvanized Coating Rust Resistant Paint Silver Effect Zinc Aluminum Spray Paint

>> Bestlink Hot Sell DTH Down The Hole DTH Drill Hammer with Good Quality

>> Deye Low Frequency 48V 8 10 12Kva 3Ph Mppt Hybrid Grid Solar Power Inverter Price With Wifi

>> Belfone High Resolution LCD Display 4G LTE Poc Two-Way Radio (BF-CM625S)

>> Damascus Outdoor Fixed Blade Knives Knife with Sheath