Vulcanization of Hot and Cold Set Sheet by Rubber Calender

| US$141.72-283.44 | 1 set (MOQ) |

Basic Info.

Model NO.

XYL-300twelve inches

Certification

CE, ISO

Condition

New

Customized

Customized

Automatic Grade

Automatic

Structure

Horizontal

New Materials

Environmental Protection

Hardness

Rigidity

After-Sale Protection

24 Hours After Sale

Mill Supply Wholesalers

Stable Performance

Free Debugging

Technical Assistance

Cable Works

Silica Gel Industry

Shoe Factory

Hose Factory

Simplicity of Operator

No Corrosion, No Deformation

Recycled Rubber

Conveyor Belt

Conveyor Belt

Seal

Running Smoothness

Energy Conservation

Timely Delivery

Simplicity of Operator

Meet a Criterion

Standard for Safety

Long Life

High Efficiency

Transport Package

Pallet Gluing Machine

Specification

1000-74500kg

Trademark

junlin

Origin

Qingdao

HS Code

8477800000

Production Capacity

800 Units/Year

Packaging & Delivery

Package Size

600.00cm * 600.00cm * 600.00cm

Package Gross Weight

3000.000kg

Product Description

Product DescriptionProduct introduction

The double-roll open rubber mixing machine is referred to as the open rubber mixing machine, which is one of the basic equipment for rubber product processing.

The company can provide raw material mixers according to customer requirements to reduce labor intensity.Calendering is suitable for the manufacture of simple sheet and plate-like products.

It is to mix rubber mixing by calender pressed into a certain shape and size of film method is called rolling forming.

The uniform material can be fed into a calender, hot press or other processing machinery to make rubber or plastic products. The single output reducer adopts rolling bearing structure, and the roller can be a boring groove roller or a drilling groove roller.

Application program:

Plasticizing of raw glue; Compound mixing; Warm mixing of mixed glue and compound; Rubber material tablet; Remove impurities from compounds; Raw rubber grinding, cleaning; Recycled rubber crushing, mixing, pressing; Raw rubber sheet, etc. In addition, it is also widely used in plastic processing and paint pigment industry production.

This machine is used to mix raw rubber, synthetic rubber, thermoplastic or E.V.A. with chemicals to make it a uniform material.

Depending on the scope of application, it can be used for mixing, refining or pressing.Humanized design

Years of industry customization experience, rich research and development experience, intimate after-sales team to serve you!

Fine workmanship

The process is mature, the finished surface is smooth and flat, the precision is high, and the operation is smooth.

Strict quality inspection

Products are inspected before leaving the factory, multiple quality testing processes, low failure rate.

Factory supply

There is no middleman to earn the difference, directly to the customer, to give you a real discount.

Product Parameters

| Model ltem | XY-2Φ252*720 | XY-2Φ360*1120 | XY-2Φ450*1500 | XY-2Φ550*1830 | XY-2Φ610*1730 | XY-2Φ710*2130 | XY-2Φ810*2430 |

| (m/min) Linear speed of front rollers | 1.2~12 | 3~20.2 | 2.5-26 | 3-30 | 5.4~54 | 8-50 | 4~40 |

Speed ratio of front and rear roller | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 |

| (mm) Max product width | 580 | 920 | 1250 | 1600 | 1500 | 1850 | 2150 |

| (mm) Min product thickness | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

Motor power(kw) | 15 | 37 | 45 | 75 | 90 | 110 | 160 |

| (mm) Overall size L*W*H | 3950*1110*1590 | 5400*1542*1681 | 7013*1595*2446 | 7200*1760*2760 | 5987*1860*2988 | 8150*3760*3630 | 8690*3139*4270 |

| (T) Weight | -5 | -11.5 | -14 | -24 | -30 | -49 | -62 |

| Model ltem | XY-3Φ252*720 | XY-3Φ360*1120 | XY-3Φ450*1500 | XY-3Φ550*1500 | XY-3Φ610*1730 | XY-3Φ710*2130 | XY-3Φ810*2430 |

| (m/min) Linear speed of front rollers | 1.2-12 | 3~20.2 | 2.5-26 | 3~30 | 5.4~54 | 8-50 | 4-40 |

Speed ratio of front and rear roller | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 | 1:1:1 |

| (mm) Max product width | 580 | 920 | 1250 | 1300 | 1500 | 1850 | 2150 |

| (mm) Min product thickness | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

Motor power(kw) | 22 | 45 | 75 | 110 | 160 | 185 | 132KW*3 |

| (mm) Overall size L*W*H | 3950*1720*1210 | 6500*1500*2440 | 7320*2200*2900 | 7550*2400*3800 | 7010*3950*3730 | 7650*4560*4080 | 11400*3200*5050 |

| (T) Weight | -5.5 | -14 | -21 | -35 | -42 | -67 | -110 |

| Model Item | XY-4Φ230*630 | XY-4Φ360*1120 | XY-4Φ400*1200 | XY-4Φ450*1400 | XY-4Φ610*1730 | XY-4Φ700*1730 | XY-4Φ710*2130 | XY-4Φ800*2500 | XY-4Φ860*2500 |

| (mm) Working diameter of rollers | 230 | 360 | 400 | 450 | 610 | 700 | 710 | 800 | 860 |

| (mm) Working length of rollers | 630 | 1120 | 1200 | 1400 | 1730 | 1850 | 2130 | 2500 | 2500 |

Speed ratio of front and rear roller | 1:01:01 | 0.73:1:1:0.73 | 1:1.38:1.38:1 | 1:1.5:1.5:1 | 1:1.4:1.4:11:1.4:1.4:1.4 | 0.5-1 Adjustable | 1:1.5:1.5:1 | 0.5-1 Adjustable | 0.5-1 Adjustable |

| (m/min) Middle-roll linear speed | 2.1-21 | 2-20.1 | 3-26.3 | 2.5-25 | 8-50 | 4-40 | 3-30 | 4-40 | 4-40 |

| (mm) Adjusting nip range | 0-10 | 0-10 | 0-10 | 0-10 | 20 | 0-30 | 0-20 | 0-30 | 0-30 |

| (mm) Min product thickness | 0.2 | 0.2 | 0.2 | 0.2 | 0.15 | 0.2 | 0.15 | 0.2 | 0.2 |

| (mm) Production calendaring width | 500 | 920 | 1200 | 1250 | 1500 | 1600 | 1900 | 2200 | 2200 |

| (kw) Motor power | 15 | 55 | 75 | 110 | 185 | 90KW*2110KW*2 | 220 | 132KW*4 | 160KW*4 |

| (mm) Overall size L*W*H | 3800*390*1890 | 3300*940*2350 | 6400*1620*2490 | 6500*1970*2740 | 6580*2460*2920 | 9950*3600*4870 | 7010*4150*3730 | 10400*3900*5140 | 12000*3800*5850 |

| (T) Weight | -4.8 | -16 | -20 | -23 | -50 | -110 | -100 | -130 | -180 |

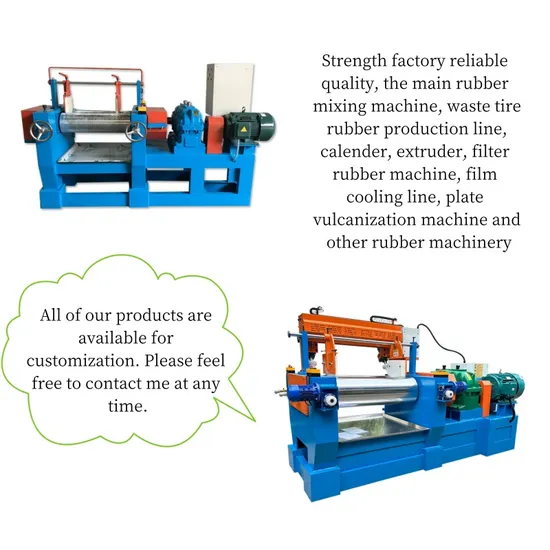

Strength factory field equipment direct shooting

Certifications

Company Profile

Qingdao Junlin Rubber Machinery Co., Ltd. is a rubber machinery technology enterprise integrating research and development, production and sales, with advanced machining equipment and precision testing instruments. Located in Huangdao District, Qingdao City, Shandong Province, 53 kilometers from Qingdao Jiaodong International Airport and 25 kilometers from Qingdao Port, the geographical position is superior.

The company has a series of advanced mechanical processing equipment, relying on quality service, advanced equipment and excellent technical strength, through continuous innovation and development, Qingdao Junlin Machinery Co., Ltd. has established a stable business relationship with many customers at home and abroad, and gradually set up an image in similar factories.

Our main products are: open mill series, automatic rubber mixing device series, rubber calender series, rubber plate cooling line series, plate vulcanization machine series, recycled rubber equipment series, rubber powder production equipment series. The company has been identified as a high-tech enterprise, specializing in special new enterprises, the company has passed iso9001:2015 quality management system certification, has a number of utility model patents and software Copyrights.

The company has passed iso and CE certification, products are sold all over the world, but also exported to the United States, Russia, Thailand, Egypt, Brazil, India, Sri Lanka, Nigeria, Chile and other more than 70 countries.

Factory strength demonstration

The company has a variety of products to meet different needs; Advanced technology to ensure high efficiency, stability and continuous innovation; Quality assurance, strict control and durable and reliable; Thoughtful service, pre-sales customized solutions, after-sales installation and debugging; Wide market coverage, good reputation.

Our Advantages

1. The main operation adopts the touch operation interface, intuitive and easy to operate.

2. The main machine adopts two motors to control two rollers respectively, with stable power and smooth rotation.

3. The electrical part adopts Germany Siemens, stable operation.

4. In sheet production, automatic sequence control is adopted, the front and back spacing is mainly limited to 5 hosts, and both sides of the winding and winding mechanism are respectively used for coil production.

5. Equipped with American imported hydraulic cylinder, precision hydraulic station, large pressure adjustment range, pressure stability.

6. Equipped with receiving and discharging EPC deviation correction device, so that the material entering the host and discharging, do not offset on the same reference line.

7. The main machine roller is made of special steel forging and finishing, with strong hardness and pressure resistance.

8. The machine can meet a variety of process production methods, equipped with a variety of rolling schemes, to meet the different shipping requirements of customers.

FAQ

Q1: Where is your factory located?

Qingdao Junlin Machinery Co., Ltd. is located in No.9 Tangdao Wan Road, Huangdao District, Qingdao City, China

Q2: Are you an integrated supplier of rubber machinery?

Yes, we can provide complete solutions according to customer requirements.

Q3: How about quality control in your factory?

Our company has SOP(Standard Operating Procedure), and all production steps must be carried out in accordance with SOP. Each machine must operate automatically for at least 72 hours and must be carefully checked before shipment.

Q4: Do you offer pre-sales service?

Yes, we have an experienced pre-sales team to provide customers with machine, technical, water, electrical, plant machine layout and other support.

Q5: How is the after-sales work? Can you send engineers to our country to help debug and install machines?

Yes, of course. We have many experienced overseas service engineers. They will help you install the machines and train the workers.

Q6: When is the delivery time of the machine?

In fact, the delivery time of the machine depends on the choice of machine. Under normal circumstances, the delivery time of standard machines can be within 30-45 days

Q6: What is the warranty period of this machine?

The warranty period of the whole machine is 12 months, and the key parts are guaranteed.

Q7: Do you provide spare parts for the machine?

Yes, our company will provide a set of standard spare parts to customers according to different machines.

>> LCD Display Digital Pocket Size Green Electronic Multimeter

>> Household Hand-Made Electronic Coffee Scale Kitchen Tea Coffee Milk Tea Waterproof Portable Gram Scale (BRS-PS01)

>> Pouch Laminator Machine 90 Seconds Warm-Up Film Laminating Machine Handheld Laminator laminadora en caliente

>> China Factory Cheap Price Genuine Leather Military Style Tactical Combat Boot

>> 2 Cores Shielded Communication Wire

>> Galvanized Perforated Metal Mesh for Decorative Ceiling

>> Fully Automatic Nail Making Machine /Nail Making Machinery

>> low cost factory price high speed automatic small mini automatic flow pack horizontal rotary food pillow packing machine

>> 600m Dual-Band 2.4G/5g Wireless Network Card and Bluetooth 5.0 Adapter 2 in 1

>> Portable Cute Bear Mini humidifier Usb Purify Air Cooler Mist Ultrasonic Humidifier for Car Office Bedroom

>> Weljia 9" X 5 1/2" Wooden Serving / Cutting Board Bread with 4" Handle

>> 6090 China Factory Price UV Flatbed Printer for Golf Ball PVC Card Phone Case Glass Bottle Wood Pen Bag Printing Machine

>> Jingchuang Hot Sale CNC Hydraulic Bending Machine for Aluminium Sheet, Steel Plate Press Brake

>> Heavy-Duty CNC Drilling Machine for Precision Steel Plate Processing with Advanced Drilling Equipment Efficient Steel Plate Fabrication and High-Performance

>> RBL Portable Reinforced Concrete Thickness Measuring Testing

>> Diesel Engine Electric Motor Pto Pellet Mill Good Quality Flat Die Wood Pellet Machine

>> High Quality American Style Metal Supermarket Shopping Trolley for Hypmarket

>> Customs New Gun Shoot Peg/Oil/Powder/Pepper Paintball 0.68 0.5 0.43 Colorful Paintball

>> Best Seller ODM OEM Passenger Flow Statistics Automatic Counter Sensor Ai IP CCTV Camera

>> Sample Divider-Coal Sample Instrument-Coal Sample Preparation Equipment

>> Double Rewinder Film Plastic Blown Film Machine

>> Hardware Fasteners Carbon Steel Galvanized DIN985 Grade 4.8 8.8 Nylon Lock Nut

>> Children Softshell Pants with Waterproof, Windproof, Breathable Warmth

>> Comprehensive Optical Power Meter Installation and Maintenance Device

>> Fiber Laser Cutting Machine for Metal Tubes Steel Pipes Industrial Tube Cutting Machine Round Pipe Sqaure Tube Rectangle Tube Fiber Laser Cutting Machine

>> Large sliding glass doors /modern wood door designs

>> Electronic Let-off Water Jet Loom with Cam Shedding for Polyester Yarn Fabric

>> Tsautop 2.4*1.2*0.9 Meter Stainless Steel Manual Hydro Dipping Tank

>> T3 Series Ultrasonic Bulk Water Meters Urban Water Use Ultrasonic Flow Rate Sensor

>> OEM Manufacturer Agricultural Machinery Cultivator Wear Part Plowing Body Share Machine Plow Side Panel Body Components Plough