Pet Bottle Flakes Crushing Washing Drying Production Line

| US$59,000.00-69,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

PET-QX500

Item

Pet Bottle Flakes Crushing Washing Production Line

Voltage

3 Phase 380V 50Hz or as Requested

Delivery Time

30-60 Working Days

Color

Grey or as Requested

Capacity Range

300, 500, 1000, 1500, 2000 Kg/H

Feeding Material

Pet Bottle and Flakes

Final Product Size

18-22 mm

Process

Crushing, Washing, Drying

Humidity

3-5 %

Transport Package

Wooden Case

Specification

International Standard

Trademark

chenxing

Origin

Zhangjiagang of Jiangsu

HS Code

8477900000

Production Capacity

30, 000sets/Year

Packaging & Delivery

Package Size

200.00cm * 200.00cm * 200.00cm

Package Gross Weight

20.000kg

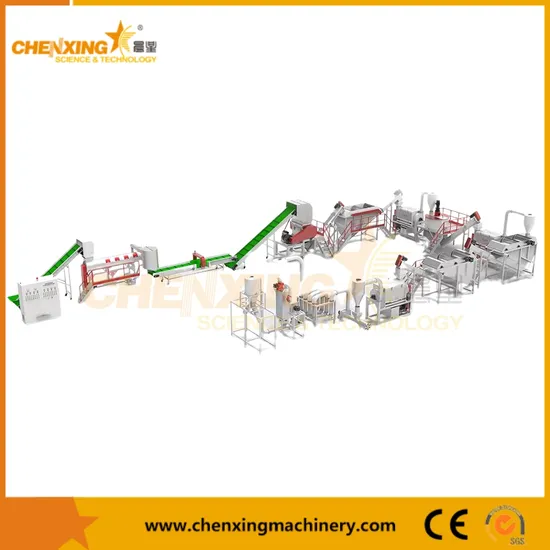

Product Description

PET bottle flakes crushing washing drying production line Product DescriptionPET bottle flake recycling and washing equipment, automatic production line, is specially used for crushing and washing waste water bottles and other PET plastic equipment. This machine is a new generation of high-efficiency, water-saving equipment developed after repeated trials by our scientific research department. The features of this machine: exquisite appearance, low energy consumption, practical and reliable output. The new rinsing device can be washed as it breaks, which greatly improves the production efficiency, and the washing material is clean, the output of the equipment is 500-3000kg/h.

PET bottle recycling and cleaning equipment mainly consists of: belt conveyor, decalcifier screw feeder, crusher, friction cleaning, rinsing tank, hot cleaning steamer, dewatering machine, label separator, silo, control electric box, etc.

Main Features

1. PET bottle flakes crushing washing and drying

2. capacity various: 500-3000KGS/H

3. label stripper for optional

4. following machines for suggestion, such as PET strap production line or pelletizing production line, etc.

Product Parameters

1.1. Material and final products:

| raw material | PET bottles and flakes |

| Capacity | 500kg/h |

| final products describe | 1.Max. moisture content:3-5% 2.Packing density:0.3G/CM3 3.Finished product size:18-22mm |

1.2. Workshop:

| Workshop | size(M*M*M): 50(L)×15(W)×5(H); Crane: equipment displacement (customers) |

| Power | 380V/50HZ,3Phases |

| Wires and cables (customer supplied) | Cabinet-connection to the power supply, all devices and connections between the electrical cabinets |

| Water supply (customer supplied) | Equipment supply |

1.3. Energy consumption

| Total installed power | 146KW (Actual consumption for the total power 70%-80%) |

| Water flow | 10-12t(can be recycling use) pressure: 0.6Mpa |

| Supply heat | Temp.: 170 ºC, Pressure output flow: 0.7Mpa |

| People | 3-6person |

1.4 Main business item:

| Project | PET bottles recycling line |

| Terms of payment | 30% T/T as the prepay, the rest should be paid before delivery time. |

| Delivery time | About 50-60 working days after receiving the deposit |

| Warranty | 1year |

Detailed Photos

Company Profile

Zhangjiagang City Chenxing Machinery Ltd. CO. was established in 2002, its predecessor is Zhangjiagang City Samsung Machinery Plastic Factory, focusing on the production of plastic machinery for more than 20 years. It is a progressive enterprise integrating new product development, product manufacturing, sales and trade in one.

The main products include: pipe, profile, sheet and pelletizing extrusion machinery, waste plastic recycling production machinery, and all kinds of auxiliary machines necessary in the process of plastic production, such as loading machines, mixers, formulators, grinding machines, mould temperature machines, chillers, etc.

We sincerely welcome customers at home and abroad to cooperate with us, and sincerely welcome to visit our company. Chenxing is willing to work with you to create a future together.

>> Customized E-Beam Welded Stripe Manganin Splicing Tape for Shunt or Resistors

>> New Nordic Personality Color Water Pattern Color Ball Glass Lamp

>> Electric Health Glass Tea Kettle

>> Wholesale Permanent Self Adhesive Courier Bag Sealing Tape

>> High Quality Senmu Tech 12.8CM 153 Wheel Hub Bolt for Car

>> ISO14001 Certified Horizon Marina Aluminum Pontoon Floating Marine Platform

>> Custom 4Efte 3 Grade Gt86 Water Vq35De Cooled Converter Made Exhaust Manifold

>> Plastic Recycling Machine PE LDPE LLDPE Film Waste PP Milk Pet Bottle Jumbo Bag Woven Bags HDPE Container Barrel Scraps Crushing Washing Production Line Plant

>> Cheap Price Horizontal Manual Sumore China Engine Conventional Gear Head Lathe Machine

>> Likesmile High Performance Steel Iron Bar Clamp Hoop Pipe Clamp Forming Making Machine

>> Automatic Transformer Oil trace Moisture Tester With Short Circuit Self Inspection Alarm

>> Industrial Fixed Electric Loading Unloading Warehouse Dock Leveler

>> Mks-4 Deep Hole Internal CNC Grinding Machine

>> Big Factory Direct Sales Rubber Calender Series Rubber Machinery

>> Factory Outlet Custom High-Quality Contact 18pin Automotive Connector

>> Pretty Gift Satin/Grosgrain Ribbon Foil Gold Festival Polyester Ribbon

>> HC-D009 Hospital Medical Supplies Digital Radiography Equipment High Frequency Mobile C-arm System

>> Car front head lamp Auto Parts front head lights for kia bongo 2003 1778948

>> Pet 120ml Plastic Healthcare Products Packaging Colorful Small Bottle Factory with Flip Top Cap

>> 5kw 6kw 7kw 5kVA 6kVA 7kVA Electric Start Portable Gasoline/Petrol Engine Power Electric Generator

>> Automatic Digital Cmyk Roll to Roll Sticker Label UV LED Label Printer Adhesive Label Printing Machine with Spot UV Varnish

>> Vmc1160 CNC Machining Centre Milling Machine Vertical Machining Center Price

>> Tool Holder Bt40 Bt50 Mill Tool Holder

>> Reliable Tyre Coupling Rubber with Customized Diameter and Black Surface Treatment/Tire Coupling Spider

>> Low Cost Barite Crushing Machine PE Jaw Crusher for Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Factory in Malaysia

>> Blade Sharpening Machine Plastic Crusher Blade Sharpening Machine Cutter Knife Sharpening Machine

>> Factory Cost Price Chinese Construction Machine Crawler Excavator 6 Ton Earthmoving with Customized Attachment Mini Crawler Excavator

>> Ce 9qsz-3000 Green (yellow) Forage Harvester

>> Global Best Sale Custom Anodized Stainless Carbon Steel Aluminum CNC Machining Parts

>> Custom Automotive Stamping Parts OEM Metal Cutting Stamping Part Metal Stamping Part