Full Automatic Color Steel Metal Iron Sheet Leveling Slitting and Cutting Machine

Basic Info.

Model NO.

cheap slitting machine

Drive Mode

CNC

Warranty

2 Years

Rolling Shaft

40crmo, Tempering to Improve Hardness

Slitting Blade

Cr12MOV,Quenched and Tempered

Controller

PLC Auto Control Whole Line

Leveling Roller

40cr Forged Steel+Quenching and Tempering

Transport Package

Standard Export Package

Trademark

KEFA

Origin

Cangzhou

HS Code

8462321000

Production Capacity

50set/Year

Packaging & Delivery

Package Size

700.00cm * 250.00cm * 170.00cm

Package Gross Weight

6666.000kg

Product Description

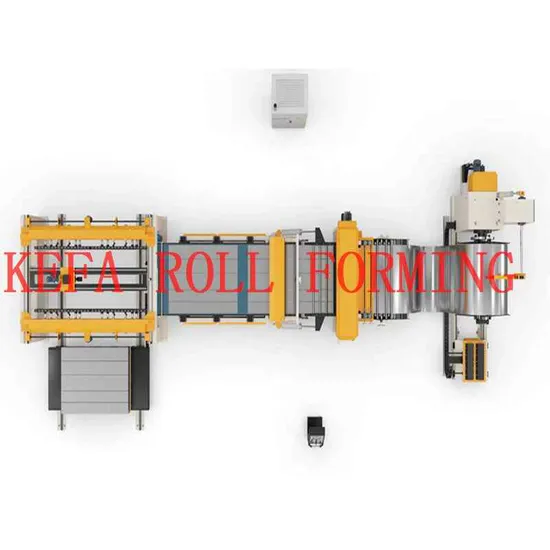

Product DescriptionMetal Plate Slitter Automatic and High Precision Metal Coil Slitting Line Machine Professional Manufacturer

The slitting machine is also called vertical slitting line which are used to slit cold rolled steel coil,hot rolled steel coil,galvanized steel coil,silicone steel coil,stainless steel coil,aluminum coils etc into different width according to the user's production demands and cut as well The smaller metal strips are recoiled at the end of the slitting machine by which these smaller strips are used necessarily for the next process usage in the professional field of making transformers,motors making industry,tube/pipe welding mill industry,Cold roll forming industry, ceiling drywall industry and other high-precison equipment making and metal strips making industries. According to the material slitting thickness there are thin plate or board slitting machine,media-thickness plate or board slitting machine and thick plate or board slitting machine. According to the metal materials there are copper strips slitting machine,stainless steel slitting machine,cold or hot rolled plate slitting machine,silicone steel slitting machine.

Product Parameters

| Project | Parameter | |

Specification | Material | HR, CR, GI |

| Thickness | 0.6mm--4.0 mm | |

| Width | 400-1600mm | |

| OD ID | φ800-2000mm Φ508-610mm | |

| Weight | 25 T | |

| Performance | Yield strength 350MPa Tensile strength 300MPa | |

| Slitting accuracy | Width tolerance: Longitudinal tolerance Burr | 0.10mm ≤0.8mm/m ≤0.1mm |

| Way of cutting | Feed cutting | |

Slitting strips | 0.6mm--1.5mm 25strips 1mm--2mm 20 strips 3.1mm--4mm 8 strips | |

| Strip width | Min 30mm | |

| Recoiler diameter | Φ508mm/Φ610mm | |

| Line Speed | 80m/min | |

| Operation height | 1000mm | |

| Total line power consumption | 290kw | |

Detailed Photos

The production flow of equipment

Coil loading car----Decoiler----loop pit 1-center aligner-----slitting machine--waste scrap winder- loop pit

2--pre-separator--tensioner---pressing separator--recoiler--manual packing-Unloading coil car

Company Profile

Certifications

Packaging & Shipping

FAQ

1.How to maintain the machine?

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.

2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) Please visit company and test machine if convenient.

>> High Quality Factory Price Aluminum Light LED Spotlight Exhibition Lighting

>> Hot sale FOR Chevrolet Buick Cruze Excelle EPICA exhaust valve 24405815

>> English Weekly Planner to Do List Daily Uppage PP Planner Schedule Notebook

>> LSR Injection Molding Machine Silicone Mold Making Machine for Cement Casting Silicone Products M, Aking Machine

>> Adblue Urea Def Dosing Pump for Mercedes A0001404478 Supply Module

>> Marine Lifting Iron Pulley Block

>> Batterie 12V 12.8V 15V 9ah Lithium Phosphate Battery Bateria PARA Carro CE/Un38.3 LiFePO4 Battery for E-Bike UPS Truck

>> Factory Direct Supply D-Type 250 Bar CNG High Pressure Natural Gas Piston Reciprocating Air Booster Compressor

>> CNC Lathe Turning Machine High Speed Spindles 8 Stations FL400

>> Customized Modular Aluminum Stand Trade Fair Booth

>> Genuine Car Bumpers For 2016+ Benz GLC Coupe C253 Change to GLC63s AMG 1:1 Grille Front rear wheel arch diffuser tips

>> Hongyou Tillage Machine Agricultural Soil Tiller Garden Soil Turner Tiller 1ks-2

>> High Quality Men Color Block Breathable 100% Cotton New Arrival 2022 Fashion Sport Wear Gym T Shirt Manufacturer

>> Heavy Duty Cordless 20V Brushless Screw Driver 95302

>> 1771-IAN Allen Bradley PLC CPU AC Input Totally enclosed Module

>> Fashion Famous Brands Designer Bags

>> 2025 Wood PVC Bedroom Interior WPC Composite Door for Apartment

>> Ybx4 Ex Motor with IP65 Rating for Safe Chemical Industry Operations

>> Taijia concrete steel bar locator rebar detector steel bar detector scanner

>> 4 Colors Polarized Sunglasses Clip on Eyewear Myopia Glasses for Fishing Driving Traveling Night Vision Flip up Sunglass Oculos

>> FT10 -2*6.8mm Linear Flat Roller Aluminum Frame Cylindrical Pin Bearing Strip for CNC

>> Motorcycle Accessories Big Twin Style Springer Front Fork

>> Children Riding Helmet Equestrian-Protective-Gear Equestrian Helmet

>> plastic empty 25kg cattle feed bags

>> Paper Sticks Making Machine Paper Rods Forming Machine

>> Industry Leading High Quality Highsun Factory Injection Molding Machine

>> Liqiang 0.15-0.85 Bare Copper Multi Wire Drawing Machine

>> Factory Wholeale Steel Full-Motion TV Wall Mount Universal Swivel Tilt Extension TV Articulating for LED LCD 32"-75" Flat Panel Tvs Wall Bracket

>> Tr Single Color Sole Mould for Static Machine One Mould One Pair

>> Multimedia LCD LED Panel 55 65 75 86 Inch Interactive Touch All in One PC Whiteboard Interactive Board