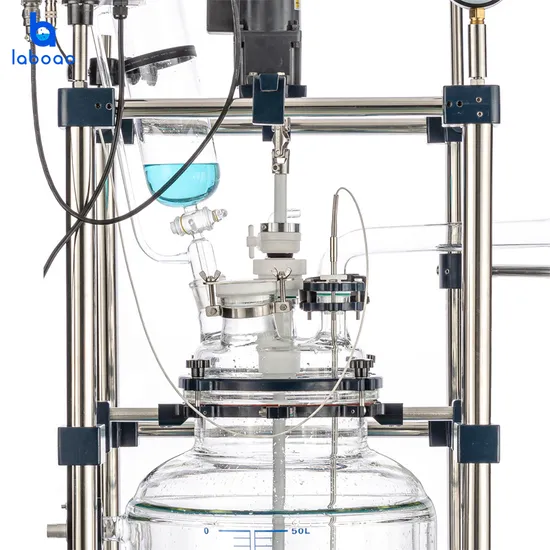

Laboao 50L Jacketed Double Layer Glass Reactor Used in Petroleum and Chemical

| US$1,700.00-1,850.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

LGR-50L

Type

Reaction Kettle

Material

High Borosilicate Glass

Capacity

50L

Structure

Set

Pressure

Negative

Agitator Model

Anchor Agitator

Tower Reactor Type

Glass Reactor

Heating

External Circulator

Heat Transfer Structure

Jacketed

Automatic Grade

Manual

Condition

New

Jacketed Volume

16L

Reaction Capacity

50L

Glass Material

Gg-17 High Borosilicate Glass

Speed

0-450rpm

Stirring Power

120W 3/1

Constant Pressure Funnel Volume

2000ml

Bear Temperature of Reactor

-80 to 250

Vacuum

0.098MPa

Port Number of Reactor Cover

6 Pieces

Voltage

220V 50Hz

Transport Package

Standard Plywood Case

Specification

170.00cm * 70.00cm * 90.00cm

Trademark

Laboao

Origin

China

HS Code

8479820010

Production Capacity

2000sets/Month

Packaging & Delivery

Package Size

170.00cm * 70.00cm * 90.00cm

Package Gross Weight

110.000kg

Product Description

Laboao 50L Jacketed Double Layer Glass Reactor Used in Petroleum and ChemicalDescription:

Jacketed Reaction vessels are used for synthetic reaction of different types of materials in a controlled temperature and vacuum environment. Reaction Vessels can be used as an all in one tool for extraction, refinement, distillation, and hemoginization.Consisting of an inner vessel with either one or two jackets, a reactor uses temperature differentials created by a chiller to change it's internal environment. Reaction vessels also operate under vacuum making them ideal for any atmospheric sensitive applications. They can be made out of glass and range in volume from 1L to 200L.

| Model | LGR-50L | |

| Kettle volume | 50L, inner diameter 365mm, outer diameter 410mm, inner length 576mm | |

| Jacketed volume | about 16L | |

| Voltage/frequency | 220V/50HZ | |

| Stirring power | 120W 1/3 | |

| Stirring speed | 0-450r/min | |

| Temperature range vessel can bear | -80 ºC to 250 ºC | |

| Temperature accuracy | ±1ºC | |

| Vacuum degree | 0.098Mpa | |

| Cover diameter | Φ265mm | |

| 6ports of cover | Stirring port | Φ50mm flange port |

| Condenser port | 50# ball mill port | |

| Constant pressure funnel port | 40# standard port | |

| Relief port | 34# standard port | |

| Temperature measure port | Φ45mm flange port | |

| Solid feeding port | Φ80mm flange port,inner diameter Φ60mm matched with PTFE cover | |

| Stirring paddle | Φ17*1000H(mm), leafing 190mm | |

| Condenser size | Φ100*700H(mm), down with Φ60mm flange port | |

| Condensation area | 0.4m2 | |

| Reflux elbow | upper with Φ60mm flange port,left with 50# ball mill plug | |

| Constant pressure funnel | 2L, upper with 29# standard port matched with glass plug, down with 40# standard plug | |

| Relief valve | 34# standard plug valve,vent nozzle (pagoda connector), outer diameter 12mm | |

| In and out circulation port of the sandwich | Φ45 flange port matched with ring flange, 4 points outside the wire adapter | |

| Baiting port | Φ75mm flanger port,Φ33mm baiting port,inclined discharging port, (pagoda connector)Φ34mm,from floor 350mm | |

| Vacuum suction nozzle | padoga connector,outer diameter 12mm | |

| In and out circulation nozzle of condenser coil | padoga connector,outer diameter 15mm | |

| Overall dimension (W*L*H) | 870*560*2270mm | |

| Net weight | 67kg | |

Features: The reactor body is made of borosilicate glass (GG-17), which has excellent physical and chemical properties, and the bottle is transparent and visible. The main body is made of stainless steel frame + aluminum alloy, which is beautiful and strong and corrosion resistant. Stainless steel stir bar is surrounded by PTFE, suitable for a variety of solvent agitation, pollution-free and corrosion-resistant. The stirring motor and the lifting motor are all low-speed booster motors, which are stable in operation, large in torque, non-sparking and long in life. PTFE components + mechanical seals, proprietary technology, good vacuum and long service life. This product governor is the speed and temperature double digital display. The speed can be set by the speed control knob, which is intuitive and convenient. It is also equipped with a temperature probe (PT100) in the kettle (the temperature of the material in the kettle can be displayed). The overall structure is compact and reasonable, with a brake universal wheel, which can be moved as a whole and is easy to operate.

>> Veneer Knife Grinding Machine

>> 1m*10m PVC Mesh Net for Motif Lights Making Christmas Decoration Lights

>> Commercial Halloween Haunted House Inflatable Maze for Sale

>> 1.82 Density of Molded Graphite Plate for Sintering Industry

>> High Quality European Standard Taper Bore Taper Bushed Type Synchronous Timing Belt Pulley Wheel

>> Industrial Rice Straw Reed Mat Weaving Machine Straw Mat Making Machine Grass Stalk Wheat Straw Curtain Sewing Knitting Machine

>> Custom Logo Cardboard Gift Sliding Box Drawer Paper Box With Clear Window for Flower Packaging

>> End Mill Sharpening Machine with Carbide Wheel Mr-X1

>> Tractor Mounted Rock Picker Stone Picker Price

>> Stainless Steel 316 Hexagonal Hole Perforated Metal Mesh Sheet

>> Wholesale New Attracting Fish Saltwater DL2C Pencil 95MM 14G Fishing Lures Cheap Fishing

>> Water Ring Pump Suitable for Pumping out Gas and Water Vapor

>> Praseodymium Metal Target Rod Granular CAS No 7440-10-0 Pr 2n5 3n

>> 2019 New 6-10 Person Inflatable River Boat/ Inflatable White Water Rafts/ Inflatable Drifting Boat

>> Customized Livestock and Poultry Breeding Equipment Galvanized Chicken Cage H Stainless Steel Layer Cage

>> Stainless Steel 500kg/H Floating Fish Feed Machine Fish + Fish Feed Making Machine Floating + Floating Fish Feed Pellet Extruder

>> cotton seed remove machine.Factory supply Cotton seeds separator machine price

>> 25t Hydraulic Traveling Head Cutting Machine/Die Cutting Machine/Punching Machine/Cutting Press

>> China PRO Mini Skidsteer Forestry Garden Mulcher Shredder for Tractor

>> XCMG Official Truck-Mounted Concrete Boom Pump 30m 37m 39m 43m 52m 58m 62m Used Diesel Concrete Pump Truck Price for Sale

>> Fully Automatic Saw Tooth Grinding Machine/Sharpener for Sawblade Sharpening Machine Price

>> PU Lining, Em694 Approved Hose, DN25X15 Meter

>> Kerosene Pressure Lantern Gas Mantle Lantern Kerosene Lantern

>> 910 Wall and Roof Panel Color Steel Panel Roll Forming Machine Full Automatic Forming Machinery for House and Factory Building Material

>> Low Price Low Sugar Strawberry Flavour Aloe Vera Drink

>> Pile Sonic Integrity Testing pile integrity test machine TFT color LCD screen

>> 165/70R13 165/80R13 175/70R13 Passenger car tyres Trailers tires wheel Rim

>> Brass Pipe Ultrasonic Heat Meter

>> Precast Concrete Pipe Cement Mold Equipment

>> China to Saudi Door to Door Cargo Service by DDP Air /Sea