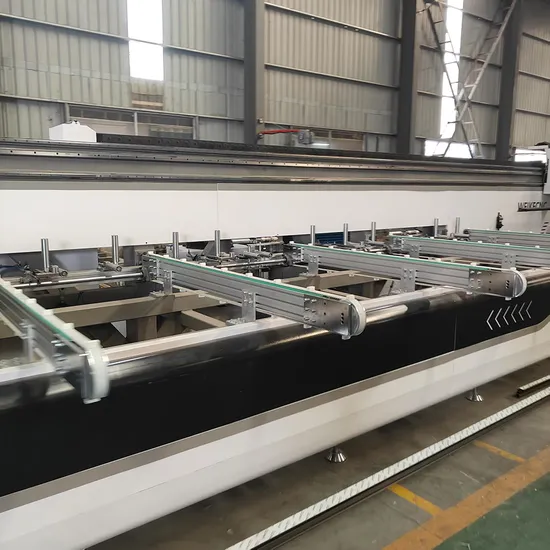

W7 CNC Cutting and Drilling Machine Intelligent Workstation for Window and Door

| US$97,000.00-107,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

W7

Condition

New

Certification

ISO

Automatic Grade

Automatic

CNC or Not

CNC

Voltage

380V

Total Power

47kw

Power Supply

380V/50Hz

Dimensions

16500*3000*2600mm

Milling Speed

0-1500mm/Min

Cutting and Milling Width

150mm

Cutting and Milling Height

150mm

Sawing Spindle

4kw

Drilling and Milling Spindle

5*3.7kw+4.5kw

Feeding Speed

0-100m/Min

Saw Blade Feed Speed

0-15m/Min

Profile Wool Training Length

1000mm-6800mm

Milling X Machining Range

0-920mm

Laser Cutting Speed

8000mm/Min

Origin

Shandong, China

Production Capacity

5sets/Month

Product Description

Key attributesEquipment attributes

| Equipment name | Door and Window Intelligent Workstation |

| Model | W7 |

Technical Parameter

| Power supply | 380V/50Hz (Three phase four wire) |

| Total Power | 47KW |

| Cutting angle | 45°~135° |

| Processing length range | 200mm at 90° (240mm at 45°)-6800mm |

| Cutting and milling width | 150mm |

| Cutting and milling height | 150mm |

| Sawing spindle | 4KW(2860r/min) |

| Drilling and milling spindle | 5*3.7KW+4.5KW |

| Feeding speed | 0-100m/min |

| Saw blade feed speed | 0-15m/min |

| Profile wool training length | 1000mm-6800mm |

| Milling speed | 0-1500mm/min |

| Milling X machining range | 0-920mm |

| Laser cutting speed | 8000mm/min |

| Blade size | φ550mm*4.7*4.0*30*140T |

| Dimensions | 16500*3000*2600mm |

| Warranty | 1 year |

Lead time

| Quantity(sets) | 1-1 | >1 |

| Lead time(days) | 20 | To be negotiated |

Customization

| Customized logo | Min. order: 1 set |

| Customized packaging Graphic customization | Min. order: 1 set Min. order: 1 set |

| For more customization details,message supplier | |

Certifications 1. This production line mainly targets the cutting, drilling, and milling of broken bridge aluminum door and window profiles and some industrial aluminum profiles. The production line first performs drilling and milling of holes and grooves on the four surfaces of the profile, as well as engraving processing, and then cuts the profile at ± 45 ° and 90 ° angles.

2. This production line achieves the processing of injection holes, pin holes, drainage holes (hidden drainage holes), corner guards, handle holes, lock boxes, door lock body holes, installation holes, and profile cutting for the system door and window profiles in one loading process.

3. 22 axis fast multi-channel multi axis linkage processing: The independent laser drilling and milling cutting unit realizes the rear laser drilling and milling line drawing, and the independent spindle milling cutter drilling and milling unit realizes the front laser line drawing and six station fast drilling and milling. The electric spindle unit is fully servo controlled to achieve four sided processing of profiles, and is matched with a customized inclined spindle drilling and milling to quickly complete the drilling and milling of various holes and grooves.

4. The high-precision spindle motor cutting unit can cut aluminum profiles for doors and windows at any combination of angles ranging from 40 ° to 140 °, with high efficiency. The tail material is treated with a 90 degree head alignment, and the saw blade avoids back cutting to prevent back cutting from sweeping the material. The front and rear cutting positions are controllable, and micro lubrication cooling is used.

5. Support batch processing or mixed processing of various door and window profiles (frames, sashes, mullions, and screen sashes).

6. The production line supports data integration with door and window design software to achieve intelligent connected production.

7. Equipped with a barcode printer, the material identification is automatically pasted onto the surface of the profile in real-time, achieving process information identification and facilitating material management and connection with enterprise ERP management software.

8. Equipped with a waste output device, it eliminates the accumulation of waste materials causing site pollution and improves the production environment.

| Specification |

Long processing life hard alloy saw blade

The high-precision spindle and saw blade ensure cutting quality and can achieve any cutting angle of 40 ° -140°.

4-station drilling and milling spindle unit

Various openings in door and window profiles can be processed in one operation, including adhesive holes, nail holes, drainage holes, handle holes, lock boxes, door lock body holes, and installation holes.

CNC feeding system

The feeding and discharging systems are fully servo controlled, fast and accurate.

Intelligent clamping system

The robotic arm can firmly grip profiles from any angle from 0 to 360 degrees, meeting the clamping and feeding requirements of various profiles.

Certifications

| Factory Introduction |

Shandong Weike CNC Machinery Co.,Ltd.is a well-known manufacturer specializing in the research, development, production and sales of aluminum doors, windows and curtain wall equipment in China. It's the most large-scale and industrialized production enterprise in the industry.

We have large production workshop and strong mechanical processing supporting capabilities, high-quality scientific research team and high-tech production team. We have strong research and development strength, perfect product system, and insists on independent innovation, improve products scientific and practical continuously. The company has several offices in China, forming a one-stop comprehensive service system integrating product development, production, sales and service.

| Packing & Delivery |

Packaging Details 1. Inside is plastic film.

2. Under the equipment is the iron tray fixed, or choose wooden box packing

3. Can also be based on customer needs for packaging QingDao Port

| FAQ |

Q:How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q:How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

Q:What customized services you provided?

A: WEIKE CNC is the true manufacturer, we have own factory, therefore we could supply full OEM and ODM service.

Q:Are WEIKE CNC machines user-friendly?

A:Yes, our machines are designed with user-friendliness in mind. They come with intuitive software interfaces that are easy to learn and operate. We also provide comprehensive training and technical support to ensure our customers can make the most out of their machines

>> Marine Lifting Iron Pulley Block

>> Batterie 12V 12.8V 15V 9ah Lithium Phosphate Battery Bateria PARA Carro CE/Un38.3 LiFePO4 Battery for E-Bike UPS Truck

>> Factory Direct Supply D-Type 250 Bar CNG High Pressure Natural Gas Piston Reciprocating Air Booster Compressor

>> CNC Lathe Turning Machine High Speed Spindles 8 Stations FL400

>> Customized Modular Aluminum Stand Trade Fair Booth

>> High-Precision CNC Drilling Machine for Versatile Six-Sided Work

>> Auto Feed Vertical Drilling Milling Machine Z5032c/1 Z5040c/1 Z5045c/1 Veritical Drilling Machine

>> Bmxp3420102 Processor, Modicon M340, Max 1024 Discrete, 256 Analog Io, Modbus, PLC Module

>> Small Barbecue Grill Cooker Portable Antique Cast Iron BBQ Oven Stove Outdoor Charcoal BBQ Grill

>> Vmc650 4axis Mini Vertical Metal CNC Milling Machine

>> Chemical Equipment Machinery Glass Lined Chemical Reactor 3000L

>> Factory Outlet Maxi Roll Paper Making Machine Production Line

>> 4m50 FUSO Canter 4D31 copper radiator MB390015 MB390017 ME417373

>> OEM/ODM 4X4 SUV Waterproof Windproof 600d Oxford Hard Shell Rooftop Tent

>> Hshc 30 Ton Manual Chain Block Hoist Lifting Tools Diesel Engine Chain Block Lever Hoist

>> Passenger Car Tire, HP Passenger Car Tyre, Run-Flat Runflat Car Tires, Yeada Farroad Saferich PCR Tires, 195/50r15 205/40r17 225/45r17

>> Original Nuvera for Xer0X Toner Cartridge Ea USA Version 006r01260 Black Toner

>> Hot sale Waste Old Cloth Recycling Tearing Machine Cotton Waste Recycling Machine

>> Single Spindle CNC Lathe Sy1600m with Taiwan Rotary Chuck and Precision Bearings

>> Concrete Pump Mixed Concrete Mixer Cement Mortar Plaster Shotcrete Machine

>> 1bj-4.4 Tractor Mounted Heavy Disc Harrow with Hydralic Folding Middle Duty

>> High Quality Headlight Headlamp for LC200 FJ200 Land Cruiser 2016

>> 15inch 16inch 17inch Customized Beadlock Car Alloy Wheel Rims with PCD 6X139.7 Offroad Aluminum Rim

>> Wholesale Factory Customized Four Wheels Electric Vehicles Ride on Cars for Kids

>> 1storm Motorcycle Modular Full Face Helmet Flip up Dual Visor Sun Shield: Hb89 Matt Black

>> Easy setting automatic 3ply facemask packing machine medical surgical face mask pillow packing machine

>> Custom Forging Brass Vacuum Cleaner Pump Impeller

>> Strength EVA Film for Glass Lamination CE Certificate Glass Laminating Interlayer

>> Colorlife Rabbit Silicone Touch Sensor Night Light for Kids Toy

>> Professional manufacturer large 2 in 1 pet food bowl raised bamboo fibre stand elevated stainless steel lifting stand holder