High Speed Kraft Paper Making Machine with Recycle Waste Paper and Wooden

| US$110,000.00-120,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

787mm 1092mm 1575mm 1880mm 2400mm 3500mm

Sheet Former Type

Fourdrinier Wire

Paper Thickness

Normal Specification Paper

Automation

Automatic

Certification

CE

Customized

Customized

Condition

New

After-sales Service

Technical Support After-Servive on Line and Video

Paper Machine Type

Fourdrinier Mesh Paper Making Machine

Net Paper Width

787-5500mm

Machine Material

Staineless Steel . Cast Iron. Cast Steel

Working Speed

5-35m/S

Moisture

1-3%

Transport Package

Container

Specification

customized

Trademark

NH

Origin

Qinyang City

HS Code

843999

Production Capacity

1-50tpd

Product Description

Full Auto Paper Making Machine

Product Description

Paper production according to the different types of paper machine is divided into: fourdrinier paper machine, cylinder mould paper making machine, crescent paper machine. More paper width is divided into 787mm, 1092mm, 1575mm, 1880mm, 2400mm, 3500mm, etc., the output can reach 1-50 TPD.

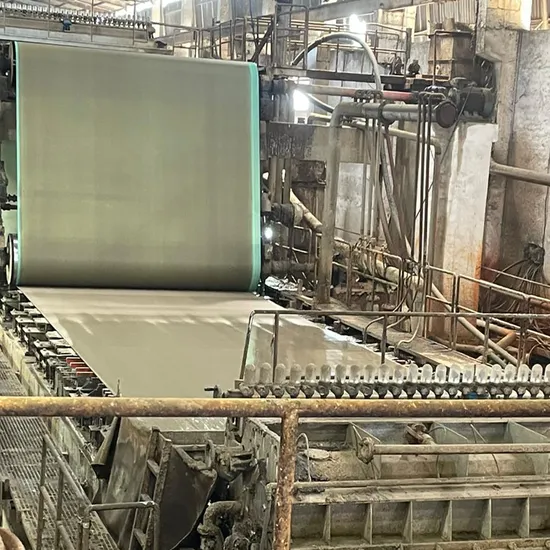

Fourdrinier mesh paper making machine has a conveyor-type forming section composed of an endless mesh. It consists of a wet section (including a headbox, a former, and a press section) and a dry section (drying, calendering, and winding).

According to the number of formers and drying cylinders, it can be divided into single long mesh, double long mesh, multiple long mesh, long mesh multi-cylinder, Yankee and other models. According to the speed, it can be divided into low-speed and high-speed.

Paper-making machines that produce newsprint are mostly adopting high-speed paper-making machines with large output, speeds exceeding 1200m/min, and widths of up to 10m.

Main Features

1.output paper :toilet paper, tissue paper

2. raw material: waste paper, virgin pulp

3.capacity: 3-50 ton per day

4. net paper width: 1092-3600 mm

5.output paper weight: 13-30 g/ m 2

6. working speed: 180-800 m/min

7. drive way: Alternating current, speed control, section drive

Product Parameters

| Output paper | High strength corrugated paper | Corrugated paper core | Template/newsprint paper |

| Net paper width | 1575-5600mm | 2400-5600mm | 2400-3880mm |

| Gram weight of finished paper | 80-130g/m2 | 55-80g/m2 | 50-80g/m2 |

| Production capacity | 400T/D | 200T/D | 150T/D |

| Design speed | 500m/min | 350m/min | 400m/min |

| Work speed | 450-500m/min | 300-350m/min | 350-400m/min |

| Center distance | 2400-7000mm | 3600-7000mm | 3600-5000mm |

| Transmission form | Frenquency control | Frenquency control | Frenquency control |

| Layout form | Monolayer layout | Monolayer layout | Monolayer layout |

| Auxiliary equipment | Closed gas hood | / | / |

| Toilet paper (Vacuum mould/crescent forming device) | Testliner board/high-strength corrugated paper | Ordinary corrugated paper | Coated whiteboard paper |

| 1092-3600mm | 2400-5600mm | 2400-5600mm | 1760-5600mm |

| 12-20g/m2 | 80-180g/m2 | 65-110g/m2 | 180-400g/m2 |

| 50T/D | 400T/D | 300T/D | 550T/D |

| 800m/min | 500m/min | 600m/min | 400m/min |

| 700-750m/min | 450-500m/min | 500-550m/min | 300-350m/min |

| 1900-4800mm | 3600-7000mm | 3600-7000mm | 2800-7000m/min |

| Frenquency control | Frenquency control | Frenquency control | Frenquency control |

| Monolayer layout | Monolayer layout | 1.5 layout | Monolayer layout |

| Breathing gas hood | Closed gas hood | Closed gas hood | Closed gas hood |

1. Fourdrinier wire part Fourdrinier wire part including wire board, chest roller and landing gear, dewatering component set, guide roller, scraper, high/low pressure spray pipe, flushing sprinkler, tensioner, corrector, white water pan, drive roller, vacuum Volt roller, fixed edge water needle, water jet needle, walking bracket and so on. Fourdrinier wire parts change clothing adopts cantilever type.

2. Press part It consists of a large roll diameter composite press and a large roll diameter. There are two nips. The press section is equipped with a guide roller, a corrector, a tensioner, a high and low pressure water spray pipe, a suction box, a scraper, a water receiving tray, a walking platform and a roll changing trolley. The press section roller bearings are grease lubricated.

3. Dryer part The surface of the dryer cylinder is chrome-plated, the thickness of the chrome plate is 0.1mm, the surface hardness of the dryer cylinder is uniform, and the unprocessed surface is smooth and tidy. The drying section is driven by a closed gear box.

4. Rewinding part

Product Process

The production process of toilet paper includes raw material preparation, paper pulping, paper making, and subsequent processing equipment can be used to achieve the general sale of toilet paper.

(1) Raw material preparation: raw materials are processed by soaking, shredding and other means to prepare for subsequent pulping.

(2) Pulping section: processing raw materials into pulp.

(3) Paper-making section: the good pulp is made into jumbo rolls of toilet paper.

(4) Paper deep processing section: jumbo rolls of paper are made into toilet paper, Kraft paper, writing paper and other saleable products.

Workshop

Packaging & Shipping

Company Profile

Qinyang NH Paper Machinery Industrial Group Co,.Ltd (referred to NH Paper) , located in Qinyang City Henan Province, is a professional machine manufacturing factory integrating design, production and sales. Its main business includes all various of paper making machines, pulping equipment, paper making mesh and paper making felt.

NH Paper has high- precision CNC machine tools and processing centers, advanced equipment and testing instruments, sophisticated technology , a strict and complete quality management system. NH Paper also gathers a scientific and technological team with professional technology and advanced level, who make full use of new technology , processes and material to ensure the stability and reliability of product.

Look forward to hearing from you sooner and establishing a long friendly business relationship with you . We promise we will do our best to help you .Besides ,welcome you to visit our factory at anytime.

>> Custom design Wholesale Price Women best polyester track suit for running Track suit

>> The Fully Connected Floating Roof Internal Floating Roof to Energy Saving

>> 600V 1000V DC 1000V 2p 10A 16A 20A 25A 32A 40A 63A Curve DC MCB Miniature Circuit Breaker for PV System

>> Agricultural Machinery Gasoline Diesel Mini Power Tiller Corn Harvester

>> 5 Axis CNC Lathe Machine B20 Dual Spindle Swiss Type CNC Lathe for Pin

>> Folding door with glass panel aluminum profile frame New design folding doors with plexiglass folding doors pakistan

>> Slip-Resistant safety walkway galvanized dimpled hole perforated punching metal sheet

>> FT8210H Electromagnetic Flow Indicator PCB Board Of Electromagnetic Flow Transmitters Liquid Measuring Devices

>> ISO 9001certified high quality big folding doors with customized sizes for the commercial building

>> Hot Black Rolled Low ASTM Mild Ss400 A36 Ms1020 Hr Cr DC01 Dx51d S355jr SPHC St15 St37 St44 St52 S235jr Low Mild Carbon Steel Sheet Factory Price

>> 6250 Lathe Gap Bed Engine Lathe Machine CS/LC6250 Turning Manual Lathe

>> Optical Metallurgical Biological Microscope Material Analysis Trinocular Inverted Metallographic Microscope

>> Natural Eco Friendly Home Decorative Simplicity Bamboo Tide Wall Clock

>> Nsrh-50 Tri-Lobe Roots Blower for Watertreatment Industry

>> off Road Two Wheels All Terrain Balance Car Self Balancing Electric Scooters

>> Vh-5 Small Single-Arm Powder Mixing Machine for Lab Mixer

>> Durable Sewn with Extra Thick Material for Family Backyard Bouncy Castle,

>> Fitness Training Dumbbell Weight Lifting Hex Dumbbell Home Gym Dumbbell

>> Cute Dinosaur Doll Large Plush Toy Doll Children′s Toy Ccreative Gift

>> High Quality Cheap Stainless Steel Ribbon Screw Mixer

>> Power Concrete Trowel with 3 6inch Combination Blade 4 Per Box

>> Giant Sportsman Inflatable Abraham Doll with Football to Netherlands

>> High Voltage Lines Tools Effective Ultrasonic Bird Repeller for Prevent Bird Nests

>> Pin Spacer with Bar for Textile Machine Parts

>> Programmable Buckle Belt Stitching Sewing Machine for Leather Belt

>> Fashion Knitwear Jacquard Christmas Men′knitted Pullover Sweater Male Knit Clothes

>> Photoelectric Sensor with Adjustable Sensitivity and Range

>> Factory Supply Rutile Grade TiO2 R698 Rutile Titanium Dioxide

>> Shilong Papermaking Machinery Waste Paper Recycling Machines Corrugated Kraft Paper Evaporative Making Machine with Life Long Time Service

>> Indoor Decoration Realistic Flower Pick Wholesale Artificial Flower