New Pneumatic Paper Cone Making Machine 15% Paper Wastage

| US$82,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SANPCL-P01

Paper Core Usage

Industry

Tube Machine Type

Rolling Machine

Reelpipe Speed

45-52 Pieces/Minute

Condition

New

Process

Paper Cone Process Machine

Usage

Textile

Model

Sanpcl-P01

Power

21kw/380V/50Hz/3phases (Coal Heating Drier)

Power Supply

45kw/380V/50Hz/3phases (Electric Heating Dryer)

Speed

50PCS/Min

Operator

2 Persons /Shift

Working Space

14000X7000X4000mm

Transport Package

Seaworthy Packing

Specification

As model

Trademark

San

Origin

China (Mainland)

Production Capacity

50 Sets/Year

Product Description

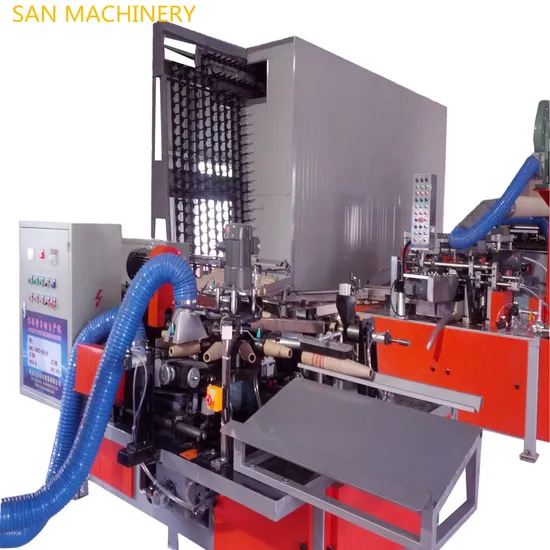

SECTION ONE:-PRODUCT DESCRIPTION:Video:https://youtu.be/PlPc1lLfjcQ

https://youtu.be/tnK7dCRmKRE

https://youtu.be/eJpYmfPkfos

https://youtu.be/NEOqpvtOm5I

https://youtu.be/IzAF2NK6Vbc

1.Brief Introduction:

This machine is a fully automatic paper cone production line for textile industry.It is controlled by PLC.It consists of paper cone winding unit,electrical/coal heating drying oven,and paper cone finishing unit. One set of mold will be delivered together with machine.

2.Technical Parameters:

| Technical Parameters: | |

| Model | SANPCL-P01 |

| Power | 21KW/380V/50HZ/3Phases (Coal Heating dryer) |

| 45KW/380V/50HZ/3Phases (Electric Heating dryer) | |

| Speed | 45-52 pieces/minute (Normal actual speed 50pcs/min) |

| Operator | 2 Persons /shift |

| Working space | 14000X7000X4000mm |

3.Configuration & Features: -- Save paper. Very low waste: 15%

-- Easy Operate. High efficiency.

-- Durable &Easy adjustment. Paper cutting driven by Japan SMC cylinders.

-- No use of cam. Higher efficiency than old mechanical type cone making machine.

-- High-precision& Long service life .Paper patterns delivered by Precision linear module driven by servo motor. Long service time.

-- Controlled by Delta PLC, Delta Inverter, and Delta touching panel

-- Sucking paper on spindle by Japan Orion vacuum pump.

-- Cone winding driven by Delta servo motor.Rolling circle can be set freely. Winding tightly. Very good cone roundness (ID tolerance 0.25mm, length tolerance 1mm)

-- Machine runs very stably. New vertical type cone finishing machine: Simple machine, not complex. Easy operate, less maintenance. Only a few of parts need to be changed when cone size changes.

4.How the machine works?

https://saninternational.en.made-in-china.com

5.Exhibition

6.Testing & Packing

We testing every machine before shipment.

The machine will be packed and shipped by container.

The machine will be packed by film in standard.

Pls note that The client can choose export standard wooden box packing or export standard wooden pallet packing.

>> Factory Supply Drink Roronoa Zoro One Piece Wholesale Japanese Anime Plastic Figure Statue Toy

>> Factory Directly Sell Single Row Grass Crop Straw Silage Forage Harvester Machine for Turkey

>> 10000mAh Built in Charging Cable LED Flashlight Portable Mobile Power Bank for Android and iPhone Phones

>> Universal High Quality Knee Type 4hw Horizontal Vertical Turret Milling Machine

>> Deepsea Sea Fishing Best Value Solid Carbon Fiber spinning Fishing Rod 2 sections

>> Direct Chrysophenine G 150% Yellow 12 for Paper Textile

>> JOHNCOO Bait Small Soft Worm Fishing Lure Silicon Twister Tail Lure Soft Bait Lure

>> Classic Golan Stone Color Coated Metal Roof Tiles Production Line Wave Roman Africa Roof

>> Bumper Weight Plates Cast Iron Disc Rubber Weight Dumbbell Plate

>> Doctor Cap Disposable Non Woven Surgical Cap Making Machine OEM

>> Precision CNC Machining Center Vmc 850 Vertical Milling Machine

>> Professional Type IIR 3 Ply Ear-loop Medical Face Mask Disposable BFE99% Surgical Face Mask

>> Elegant Luxury Stylish Restaurant Furniture for Upscale Restaurants

>> Dmtg CDS6266b Dalian Machine Manufacture Conventional Lathe

>> AA1100 H14 3003 8011 A3003 6061 7075 Aluminum Coils

>> Slant Bed Pricision CNC Turning Lathe

>> 2023 River Water Aquatic Weed Conveyor Harvester

>> ERW High-Frequency Straight Sewing Pipe Making Machine Automatic Production Equipment/Welding Machine

>> FAW truck parts J6 J5 truck 3506405-91W multiple unit valve joint Shandong Hasing

>> Yc-Vc750 Industrial Automatic Vegetable Cutting Chopping Dicing Food Machinery Vegetable Processing Machine

>> Carbon Fiber Tube, Carbon Fibre Telescopic Pole

>> SSAW Gas Hot Roll Cold Roll Spiral Steel Structure Oil Water Winding Drum Civil Air Defense Works Tank Hydraulic Pressure Testing Spiral Pipe Making Machine

>> Heavy Type Compound Crusher with Plate Hammer for Fine Crushing

>> Powder Extract Wholesale Cyamposis Tetragonolobus Guar Gum 80% Galactomannan GM

>> Ht-110 Cutting Impact and Punch Down Tool

>> Prestressed Concrete Pipe Pccp Steel Cylinder Steel Cage Welding Machine

>> Toolstation Garage Commercial Civil Use Small Household Pool Dehumidifier

>> wholesale price Custom color Sublimation Printing football soccer jersey uniform sports wear for soccer team

>> High Quality Flexible Rubber Water Suction and Discharge Hose

>> Hot Products RF Coaxial Cable Coaxial MCX Plug MMCX RG316 F Male Connector Industrial 1000M Min JY1001-4D Brass/plastic CN;JIA