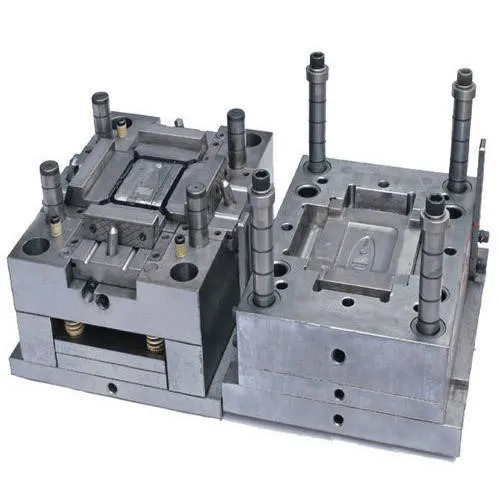

OEM Zinc Alloy Aluminum Die Casting Mould Aluminum Casting Mould

Basic Info.

Model NO.

AIKEHAN

Demoulding

Automatic

Surface Treatment

Heat Treatment

Using Hardness

>HRC45

Average Wall Thickness

>3mm

Mould Life

500,000-1,000,000 shots

Certification

CE

Customized

Customized

Condition

New

The Best Tolrance

0.0005

Surface Roughness

Ra0.8-1.6

Design Software

Solidworks

Inspecification

100%Before Packing

Fixture

Custom

Lead Time

30-60days

Mould Material

Fsh13

Process

Die Casting and CNC Process

Transport Package

Carton, Wood Box, OEM

Specification

oem

Origin

China

Production Capacity

5000/Month

Packaging & Delivery

Package Size

40.00cm * 30.00cm * 30.00cm

Package Gross Weight

5.000kg

Product Description

Zinc Alloy Aluminum Die Casting Mould Aluminum Casting MouldProduct Description

| Product Name: | Customized aluminum die casting part |

| Material: | ADC12, A380 aluminum alloy,Alsi9cu3,Alsi8cu3 |

| Standard: | DIN, GB, ISO, JIS, BA, ANSI |

| CNC Min.tolerance: | 0.005mm-0.1mm |

| Certificates: | TUV,ISO 9001:2015,IATF 16949 |

| Surface treatment: | Anodizing, sandblasting,Powder Coating, zinc/chrome/nickel/silver/gold Plating, Polish, Nitriding, Blacking, Painting, Heat treatment etc |

| Die casting machine: | From 180Ton-1250Ton |

| Production process: | Drawings→ mould making → die casting →rough machining → CNC machining →surface treatment →product checking→ packing →delivery |

| Size: | Requsts of customers drawing |

| Type of die casting machine: | Cold chamber die casting machine |

| CMM: | Yes |

| MOQ: | 100pcs, according to your drawings |

| Drawing: | Provide by customer, or design according as the sample |

| Service: | Offer assembly if customers need |

Die-cast aluminium molding is a process developed in the United States during the mid-19th century where a molten metal, or alloy, is injected withhigh pressure into a metal mould. Once the injected metal has solidified, the metal mould is opened and the piece in die-cast aluminium is extracted.

The mould to make the die-cast aluminium molding is made of steel and consists of two shells to allow the extraction of the die-cast part. The materials used to make the various parts of the mould are always metals with higher melting points than the injected material, such as aluminium.

The injection pressure of the molten material may vary depending on the weight of the piece to be obtained, but also the type of melting material used. It is important that the pressure is kept constant throughout the melting process until the workpiece solidifies. In the meantime, hydraulic presses ensure perfect and complete closing of the mould: once the piece has solidified, the presses allow the two semi-moulds to open so that the die-cast part can be extracted.

Process of die-casting aluminium molding

The process of die-casting aluminium molding is automatised and computerised and therefore lends itself to high productivity. The constant control of the casting process ensures the best possible quality of die-cast parts and maximises the production efficiency of their plants.

Thanks to the high technological and quality standards achieved today by equipment and machinery, the pieces produced by die casting ensure better minimum dimensional tolerances and surface finishes than other foundry processes.

Thanks to the modern die-casting systems of aluminium and zinc alloys with capacities ranging from 100 to 1400 tonnes, Italpres is able to manufacture high tech items with weights ranging from 4 grams to 15 kilos, either in small, medium or large scale production.

Company Profile

>> Hot Sale Small Forklifts Manual Forklift Portable Electric Stacker

>> Cooking Stove Four Burner Black Tempered Glass Gas Hob (JZG54001C)

>> DSQC609 ABB module supply

>> Hot Sale Street Solar LED Traffic Safety Warning Light

>> Cheap Price Sunny Gray Porcelain Ceramic Marble Tiles

>> One-way disc plough 1LY-425 for JINMA tractor

>> Lab Scale Melt Spinning Machine Accessories Copper Gasket

>> Soldering N female type connector bulkhead to PCB mount straight

>> Fitness Equipment Workout Multifunctional Adjustable Bench Se

>> 4000b/H 500ml Plastic Injection Blow Molding Machine

>> 4 Post Vehicle Car Lift Floor to Floor Elevator Car Parking Lift

>> 1ton 2ton 3ton 5ton Electric Wire Rope Stainless Steel Drum Prop Pulling Winch

>> Popular Summer Water Gun Cute Backpack Water Gun for Kid

>> Kent Surface Grinder Surface Grinding Machine for Sale Kgs-615ahd

>> Sany Sy16c 1.75tons Mini Garden Hydraulic Excavator with Retractable Chassis Price for Sale

>> Advanced Smart Ice Maker with Multi-Functional Water Purification, Instant Heating, and High-Capacity Cooling

>> Roll Forming Machine Manufacturers in China

>> Intelligent Bird Prevention Equipment Relies on Solar Energy and Uses Ultrasonic Voice to Protect Outdoor Fish Ponds and Other Areas

>> Electric aluminum roll shutter with PVC sliding windows bulk vinyl windows conch profiles slim insulated glass

>> Accident-Reducing Galvanized Traffic Barriers for Road Safety Highway Guardrails OEM

>> Glass Fiber Speaker Cone, Rubber Edge for Loudspeaker Accessory

>> for Water-Coal Gasification Furnace, Explosion Welding Process, Special Coal Slag Crusher

>> Doorhan Transmitter 2 PRO 4 PRO Wireless Remote Garage Door Lock Gate Key Dorhan 2 Rpo2button433m

>> Womens new design High Waisted Ripped Knee Jeans Ladies Skinny Stretchy Jeggings Pants Size

>> Automatic Poultry Equipment Steel H-Type Broiler Cage System with Ventilation Fan Technology

>> How to choose the correct type of charging pile cable?

>> Custom Paper File Folder & Cardboard 3 Ring Binder

>> Double Battery Type 200km Fast Food Cargo Delivery Electric Bike Electric Scooter

>> 2W 2 Way Direct Acting 2/2 Normally Closed Nomal Open Waterproof Solenoid Pneumtaic Water Air Liquid Oil Brass Stainless Steel Small Big Orifice Control Valve

>> China 52cc Mini Gasoline/Petrol Power Rotary Weeder Tillers for Farm Agricultural Ploughing Machine Cultivator