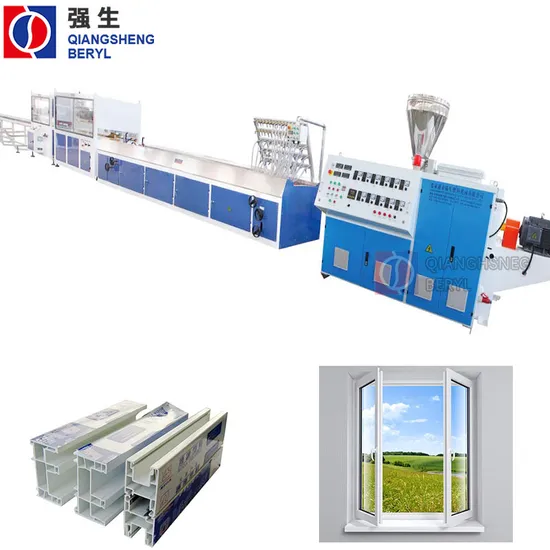

Automatic UPVC Profile Window Machine Manufacturing/UPVC Window Making Machine

| US$20,000.00-45,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

SJSZ65/132

Condition

New

Certification

ISO, CE

Automatic Grade

Automatic

CNC or Not

not CNC

Voltage

380V

Name

Door Frame Make machine Plastic Extruder

Inverter Brand

ABB

Motor Brand

Siemens

Temperature Controller

Omorn

Capacity

150-300kg/H

Suitable Material

PVC UPVC

Heating Way

Cast Aluminum Heating

Raw Material

PVC Powder

Power Supply

380V 3phase 50Hz or as Your Demand

Total Installed Power

About 80kw

Service

Rovided: Video Technical Support, Free Spare Parts

Machine Name

Door Frame Make machine Plastic Extruder

Brand

Qiangsheng

Factory Location

Jiangsu,China

Machine Size

25mx2.8mx3m

Transport Package

Wood Block Fixed Steel Wire Reinforcement

Specification

Vertical High Torque Gearbox, Bimetalic screw

Trademark

QIANGSHENG

Origin

China

HS Code

84772090

Production Capacity

300set/Year

Product Description

Product Description1.This door frame make machin plastic extruder can produce PVC UPVC window door profile, PVC ceiling, PVC window sill, PVC door, PVC cable trunking and other profiles.2.The door frame make machin plastic extruder is composed by twin screw extruder, vacuum calibration and forming table, haul off machine, cutter, stacker.

3.The door frame make machin plastic extruder can choose different specifications of conical twin-screw extruders according to different profile sections and molds, and configure the corresponding vacuum calibration table, tractor, cutting machine, stacker and other auxiliary equipment such as PVC hot and cold mixer,PVC miller and Crusher etc..

Machine working process

Raw material +wood power+ additive → mixing → conical twin-screw extruder → profile extrusion mould → cool molding die → vacuum calibration support → belt haul-off → cutter → rack → finished product inspecting & packing

Detailed Photos

Plastic extruder

1.World famous brand electrical component such as Siemens, ABB etc .

2.High torque gearbox with adopts NSKF bearing;

3.Bimetallic screw and barrel;

4.Intelligent PLC controlling system with human-friendly interface.

Mould

1.Material of mold body is Steel 45# ,harden treated and polished.

2.Material of inner mould parts is 40Cr.

3.The material of calibration bushing is Stannum bronze.

4.The width can be customized.

Vaccum calibration table:

1.Calibrating the pipe outer diameter and cooling pipe.

material of water tank is stainless steel 304.

Hauling off machine

1.Function :haul off stably and synchronal with extruder speed.

2.Clamping mode is pneumatically.

3.speed adjusting mode is frequency conversion.

cutter machine

1.Function:cut in fixed length.

2.Cutting type:automatic meter counting cutter.

Product Parameters

| Model | YF120 | YF180 | YF240 | YF300 | YF600 |

| Product Max size | 120x50mm | 180x50 mm | 240x100 mm | 300x120 mm | 550x120 mm |

| Extruder | SJSZ45/90 | SJSZ51/105 | SJSZ65/132 | SJSZ65/132 | SJSZ80/156 |

| Capacity | 120 kg/hr | 150 kg/hr | 300 kg/hr | 300 kg/hr | 400 kg/hr |

| Production Length | 18 m | 20 m | 24 m | 24 m | 28 m |

Auxiliary machines

Packaging & Shipping

Company Profile

Zhangjiagang Qiangsheng Machinery Co., Ltd. is professional with plastic machines . We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines.

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

>> for Heating Animal Feed Pellet Extruder Machine

>> 1000W 1500W 2000W 3000W 4000W 6000W Tube and Plate Fiber Laser Cutting Machine

>> Low Price Processing for Second-Hand Tablet/Disc Centrifuges

>> Colleague Students Canvas School Bag Travel Rucksack Backpack

>> Plastic Egg Tray and Fruit Tray Making Machine

>> Efficient 5 Axis CNC Machine, Superior CNC Machining Center (V8/V11)

>> Hot Sale Gasoline UTV Efi 500cc 1100cc Electric Start Shaft Drive 4X4 Go Karts for Dune Buggy

>> 2cbm Handling Feed Spreader Handle Style Spreader for Cow Feeding for Livestock and Dairy Farm

>> China Manufacturer Full Downdraft Semi Draft Side Downdraft Car Paint Spray Booth Equipment

>> HC-PQ053G1 Mitsubishi Servo Automatic Voltage Regulator Modular

>> Full Automatic PVC Air Blowing Shoes Injection Moulding Machine for One Head Three Colors

>> Shanghai Marya China Supplier Clean Room PVC Floor with CE/GMP Certificates

>> China Popular Glass Bottle Printer Perfume Bottle Semi Automatic Screen Printing Machine

>> Modern Design double glazed aluminium glass swing door casement doors

>> Germany Blades 4 Cartridges For Women Razor 4 Blades Private Label Available Compatible Name Brand Razor No Disposable GF-0021

>> Taijia NDT Rebar Scanner/ Integrates Rebar Locator / Concrete Rebar Detector

>> GE IS215UCVEH2A Modular

>> iPhone Xs Max 6.5 Inch LCD Digitizer

>> New Compatible Duplicator Ink Ks Ink Cartridge for Use in Ks-500/600/800

>> Polyurethane Spray Foam Equipment for Cantilever Structure Body

>> High Quality Material Asphalt Cutter Light Weight Hydraulic Saw Concrete Reinforced Concrete Wall Saw

>> Best Price Pd Series with Gantry CNC Drilling Machine for Beam Drill

>> Hydraulic Paper Card Book Die Punching Cutting Machine

>> Bean to Bar Chocolate Making Chocolate Processing Machinery for Factory Use

>> Air Pressure Water Guns Summer Hot Children Educational Toy

>> Black Silicon Carbide for Foundry

>> Donjoy SS316L Hygienic Twin Screw Pump Gear Pump with Pumpcover

>> Automatic Vulcanizing Machinery Car Parts Seals Joint Injection Machine ISO9001 Certificate

>> Universal Precisional Vertical CNC Drilling and Milling Machine Lk1010

>> Customized Rain Shower Accessory Hand Shower Bathroom Set