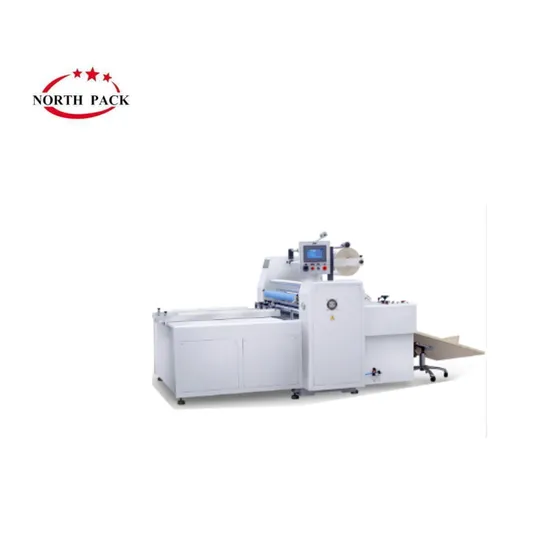

Strengthen Laminating Machine with High Quality

| US$1.00-100,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

INNOVO-520

Classification

Pre-Coating Laminating Machine

Application

Packaging Paper, Soft Board

Driven Type

Electric

Automatic Grade

Automatic

Membrane Material

Matt Film

Plastic Film Mulching Modes

Hot Laminating

Performance

Waterproof

Delivery Time

One Year

Laminating Plate Size

420mm×520mm

Max.Laminating Size

400mm×500mm

Dimension

2300×630×1650mm

Transport Package

Wooden Case

Specification

CE

Trademark

Innovo

Origin

Zhejiang, China

HS Code

8420100090

Production Capacity

300 PCS/Month

Product Description

INNOVO-520 Strengthen LaminatorIntroduction:

The machine adopts PLC Industrial automation for easy operation and high precision.HRO two-way double-acting standard cylinders are for balance pressure.Main structure is processed by casting workmanship without deformation for long service life.This machine is equipped with automatic oil return,automatic pressure make-up.Automatic and manual pressure release devices are both designed for more humanized operation.Photoelectric switches are adopted to realize zero pressure laminating and multi-pressure control which can reduce chip rejection rate effectively.The machine has five or seven opening daylights for option.It can improve 20% productivity more than similar products.High quality mica insulation materials are adopted to protect the temperature losing and save energy.

Usage:

Suitable for professional manufacturers to produce RFID cards,IC/ID inlay cards and various kinds of printing cards and magnetic stripe cards wih high quality and low-cost.

Technical Parameter:

| Model | INNOVO-520 Strengthen Laminator |

| Screen size | Imported 5.7 inch color screen |

| Controlling method | PLC |

| Cooling method | Water cycling cooling |

| Heating method | Electric heating |

| Pressure | Heating 12 stages/cooling 5 stages |

| Temperature precision | 2(ºC) |

| Pressure range and precision | (0-16-21)Mpa 0.1Mpa |

| Heating plate material | Imported aluminum alloy/good quality steel plate |

| QTY of hydraulic cylinder | Single/Hour |

| Laminating plate size | 420mm×520mm |

| Max.laminating size | 400mm×500mm |

| Laminating daylight | Five/Seven |

| Voltage | 380V 50HZ /22KW |

| Dimension | 2300×630×1650mm |

| G.W. | 2.4T |

| Productivity | 8000-10000cards/hour |

Machine transport and packing

__________________________________________________________________________

1. The packing of small machines is confirm to export wooden case standard, strong and durable. The wooden case's thickness is generally 1 cm.

2. In order to be waterproof, we usually use bubble film to wrap machine.

3. We can handle shipping for customers too.

Our Company:

_____________________________________________________________________

Certificate:

______________________________________________________________________

FAQ:

______________________________________________________________________

Q1: Are you a manufacturer?

Yes, we are specialized manufacturer of hot foil stamping machine and die cutting machine in China over 20 years.

Q2: Do you have stock products to sell?

We manufacture machines in batch. So most of machines have in stock, please check with us before ordering.

Q3: How about installation and training?

Installation and training: If purchaser's engineer travels at own cost to China, free training session. If engineer sent to purchaser's factory, all travel cost paid by purchaser.

Q4: How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator's error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product's photos and videos to make every detail clear.

Why choose us?

_____________________________________________________________________

1.Our brand "INNOVO" is well-known in our domestic market and over 70 countries and territories. Europe, South America, Latin America, Southeast Asia, Middle East, Africa etc.

2.Genuine products with excellent quality. Company has always proved the 100% quality.

3.After-sales service and technical assistance: company provides after sales service and technical assistance as per customers' requirement and needs. After-sales service provided engineers available to service machinery overseas.

4.Cost saving: lon-life, shock resistant and high reliability bearings with excellent quality and better performance, resulting in increased cost saving.

5.Less cost of purchase: We are the manufacturer directly.

6.Attendant customers queries promptly.

>> Light Weight Waterproof Outdoors Wallboard Exterior Wall Panel Flexible Tile

>> High Quality Custom Weather Resistant Graindecking for Residential Commercial Floor Projects

>> 18mm X 25mm Black Plastic Cable Wire Carrier for Lathe Machine

>> Beverage 140-160cups/Min New Smart High Speed Paper Bowl Making Machine

>> High Precision Vertical Machining Center CNC Milling Machine

>> 800 Hours Warranty Curing Glue UV Lamp

>> 3mm 4mm 5mm 6mm Environmental Antioxidant Safety PE Film Coated Edge Polished Beveled Round, Oval Copper Free Lead Free Silver Mirror Aluminum Mirror

>> Module spare parts DS200DCFBG1BNC

>> Plastic Bottle Scraps Recycle Washing Line Washer

>> Touch Display with Android OS 11/13 System

>> EA111 Timing Kit for VW Beetle 1.4 TSI OEM 03C109158A 03C109158 TK1540

>> Alarm cable Manufacturer Un-shield 2 4 6 8 12 Core Copper CCA 20AWG 22AWG 24AWG Shieled Security Alarm Cable

>> Farm Use Cow Manure Separator

>> Factory Price Cartoon Mario Cartoon Game Characters Embroidery/Woven/Sequin/Chenille Logo Cloth Patch Custom Patch Applique Patch

>> Sinobi Creative Sport Watch For Man Silicone Band Wristwatch Leather Band Reloj Double Dial Yellow Watch S9845G

>> A4144660101 Power Steering Pump for Mercedes Truck 4144660101

>> Shackle, Wire Rope Clip, Turnbuckle,316/304 Stainless Steel Materil Boat Accessories Precision Casting Marine Hardware Rigging for Spring Hook Chain,Link Chain

>> Scoop bottom Plain Tank top cotton spandex jersey tanks wholesale gym wear for men

>> Hz Blue Flat Panel Lacquer High Gloss Pet Profession Design Modern Kitchen Cabinet

>> Z3050 High Quality Radial Drilling Machine with CE High Speed Good Rigidity China in Stock

>> Portability-Enhancedelectric Blocks Making Machine

>> CNC High Speed Angle Steel Marking and Drilling Line in Power Tower and Communication Tower, Bl3635, Angle Size 360*360*35mm

>> Magnetic Nut Setter Hex Socket Bit Nut Setter Driver Bit

>> ASME Horizontal or Vertical Type Compressed Air Surge High Pressure Tank

>> Custom High Quality Printed Logo Non Woven Fold Garment Suit Cover Men Non Woven Suit Bag with Zipper for Clothes

>> Indoor Adult Trampoline Amusement Park Equipment Outdoor Kids Playground

>> Mini Office Paper Shredder Machine

>> LDPE Film Washing Machine, Plastic Recycling Plant Price

>> Mindray bc5390 used hematology analyzer blood fully automatic hematology analyzer price

>> Beige Horse Riding Pants for Women Horse Riding Breeches Equestrian Clothing