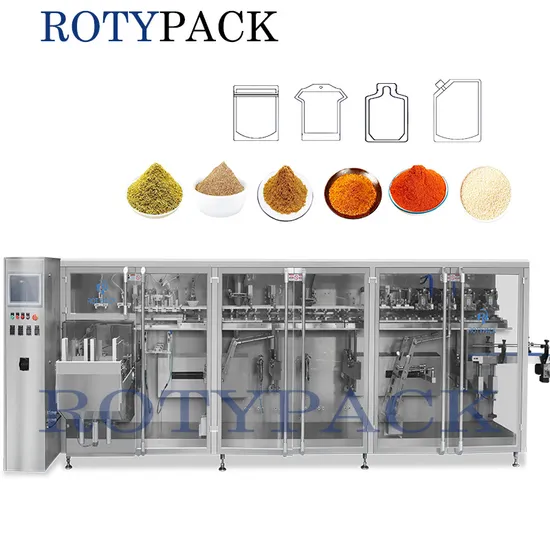

Rotypack Zipper Stand-up Pouch Horizontal Packaging Machine Filling Ketchup Sause

| US$40,000.00-90,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

RT-260GS

Type

Piston Filling Machine

Automatic Grade

Fully Automatic

Material Type

Paste

Filling Valve Head

Multi-Head

Feed Cylinder Structure

Multi-Room Feeding

Packaging Container Lifting Structure

Pneumatic Lifting

Structure

Linear

Packaging

Bag

Packaging Material

Film

Max.Filling Volume

1800ml

Max.Dimension

240mm*320mm

Capacity

30-60PCS/Min

Material

Composite Bags or Heat Sealing Materials

Motion Drive

Servo Motor Drive

Transport Package

Wooden Case

Specification

20-5000ml

Trademark

Rotypack

Origin

Shanghai China

Product Description

Product Parameters| Specifications of pouch | Model | RT-210G | RT-240G | RT-330G | RT-260GS | RT-330GS |

| Specifications of pouch | Stand-up pouch/with zipper/in irregular shape | Stand-up pouch/with zipper/in irregular shape | Stand-up pouch/with zipper/in irregular shape | Stand-up pouch/with zipper/in irregular shape | Stand-up pouch/with zipper/in irregular shape | |

| Material | Composite bags or heat sealing materials | Composite bags or heat sealing materials | Composite bags or heat sealing materials | Composite bags or heat sealing materials | Composite bags or heat sealing materials | |

| Min.Dimension | 90*95*25mm | 120*130*25mm | 150*200*25mm | 90mm*140mm | 150mm*150mm | |

| Max.Dimension | 210*300*50mm | 240mm*320mm*50mm | 310mm*480mm*60mm | 240mm*320mm | 310mm*480mm | |

| Max.Filling volume | 1000ml | 1500ml | 2000ml | 1800ml | 3000ml | |

| Capacity | 30-50pcs/min | 30-50pcs/min | 30-50pcs/min | 30-60pcs/min | 30-45pcs/min | |

| Quantity out per batch | 2 | 2 | 2 | 1 | 1 | |

| Motion drive | Cam drive | Cam drive | Cam drive | Servo motor drive | Servo motor drive | |

| Operation parameters | Power | 3.5kw | 3.5kw | 5.5kw | 9.5kw | 10kw |

| Operation pressure | 0.8Mpa | 0.8Mpa | 0.8Mpa | 0.8Mpa | 0.8Mpa | |

| Gas consumption | 0.7m3/min | 0.7m3/min | 0.7m3/min | 0.7m3/min | 0.7m3/min | |

| Voltage | AC380V, 50Hz | AC380V, 50Hz | AC380V, 50Hz | AC380V, 50Hz | AC380V, 50Hz | |

| Decibel | <75dB | <75dB | <75dB | <75dB | <75dB | |

| Machine parameters | Dimensions(L*W*H) | 3100mm*1100mm*1550mm | 3300*1100mm*1550mm | 3700mm*1200mm*1550mm | 3800mm*1200mm*1550mm | 4700mm*1400mm*1550mm |

| Weight | 2200kg | 2500kg | 3000kg | 4500kg | 5500kg |

| Specifications of pouch | Model | RT-420GS | RD-200SF | RD-300SF | RD-400SF | RD-600SF |

| Specifications of pouch | Stand-up pouch/with zipper/in irregular shape | Stand-up pouch/with zipper/in irregular shape | Stand-up pouch/with zipper/in irregular shape | Stand-up pouch/with zipper/in irregular shape | Stand-up pouch/with zipper/in irregular shape | |

| Material | Composite bags or heat sealing materials | Composite bags or heat sealing materials | Composite bags or heat sealing materials | Composite bags or heat sealing materials | Composite bags or heat sealing materials | |

| Min.Dimension | 160mm*200mm | 60mm*130mm | 90mm*140mm | 100mm*160mm | 120mm*180mm | |

| Max.Dimension | 400mm*500mm | 90mm*220mm | 140mm*250mm | 190mm*300mm | 240mm*320mm | |

| Max.Filling volume | 5000ml | 100ml | 1500ml | 1500ml | 100ml | |

| Capacity | 20-35pcs/min | 60-80pcs/min | 60-80pcs/min | 60-80pcs/min | 60-80pcs/min | |

| Quantity out per batch | 1 | 2 | 2 | 2 | 2 | |

| Motion drive | Servo motor drive | Servo motor drive | Servo motor drive | Servo motor drive | Servo motor drive | |

| Operation parameters | Power | 10.5kw | 4.5kw | 10kw | 10kw | 15kw |

| Operation pressure | 0.8Mpa | 0.8Mpa | 0.8Mpa | 0.8Mpa | 0.8Mpa | |

| Gas consumption | 0.7m3/min | 0.7m3/min | 0.7m3/min | 0.7m3/min | 0.7m3/min | |

| Voltage | AC380V, 50Hz | AC380V, 50Hz | AC380V, 50Hz | AC380V, 50Hz | AC380V,50Hz | |

| Decibel | <75dB | <75dB | <75dB | <75dB | <75dB | |

| Machine parameters | Dimensions(L*W*H) | 5300mm*1400mm*1550mm | 3230mm*1400mm*1550mm | 4700mm*1200mm*1550mm | 4900mm*1200mm*1550mm | 5800mm*1200mm*1550mm |

| Weight | 6500kg | 2200kg | 3500kg | 5000kg | 6500kg |

| Configuration of machine 1. SIEMENS or INOVANCE full servo motor motion control system. 2. Remote Module. 3. 304 Stainless Steel Rack. 4. Individual film releasing rack. 5. Ultraviolet sterilization system. 6. Stand-up pouches, three or four side seal. 7. Self-lubricating bearings from Germany. 8. Standard scissor module (die-cutting unit optional). 9. 12" Siemens mobile touch screen parts laser marking. 10. Self-lubricating system,Spare parts maintenance reminder. 11. Remote Service Function. 12. Safety door system. 13. Chassis with built-in LED light. 14. Bag exhaust device. 15. Water-cooling system. 16. Nitrogen flushing statino Nitrogen dosing station 17. Double heat sealing system Double cooling system |

Product Description

Automatic pouch packaging machine

The RT-260GS fully automatic pouch packaging machine uses thermal composite materials to package liquid, granule,powder and other contents measured in units. This equipment can produce various bag types, including three side sealing, four side sealing, stand-up bags, irregular bags, irregular stand-up bags, stand-up bags with zipper and stand-up bags with spout. It can complete the process from bag feeding, filling, sealing to finished product punching and cutting before being transported to the outside of the machine.

Our Advantages

| Advantages 1. A tech-leading pouch manufacturer in the market. 2. Reputation of extremely stable performance . 3. Full expertise of pouch filling technology. 4. Strict production management and project management. 5. 7/24 remote service support. 6. Management with SAP, ERP and CRM system. 7. Local spare parts storage. |

Detailed Photos

Details of the machine

After Sales Service

Our service

1.We have a dedicated customer service staff to call back from time to time and guarantee 1-2 visits per year by our offline after-sales engineers.

24 hours at any time to provide customers with online remote service, offline with seven experienced mechanical and electrical engineers.

We have 5 years of parts in stock for any unit we sell. We guarantee that every part of every machine is individually coded. We guarantee that each customer has an individual database of all equipment sold with traceability.

Technical documents

The technical documents need be handed over with the delivery including Packing list Equipment instructions Operation/maintenance manual Electrical schematic diagram

Installation & Commissioning

A) After the equipment arrives at the Buyer's workshop, the Buyer does unpack, the installation, commissioning and trial production of the equipment within Buyer's own packer. During the installation and commissioning, the Supplier is responsible for corresponding spare parts.

B) Training

The Supplier is responsible for technical training. The training contents includes equipment structure and maintenance, equipment control and operation. The training shall be carried out on line or on Supplier's plant. The Supplier will assign qualified technicians to guide and prepare training programs,

Company Profile

Brief enterprise honor

We have obtained the honor of national high-tech enterprises, dozens of inventions and utility patents, and an increase of more than a dozen patents every year.At the same time, we also obtained the Chinese intellectual property certification, CE certification, and the honorary title of innovative technology company.

About our company

Shanghai Rotypack Equipment Co.,Ltd

Our Factory

Shanghai Rotypack Equipment Co.,Ltd

Our exhibition

Shanghai Rotypack Equipment Co.,Ltd

Transportation support

Shanghai Rotypack Equipment Co.,Ltd

>> Custom 230g-510g Glossy/Matte Laminated Frontlit & Backlit Digital Printing PVC Coated Flex Banner for Indoor and Outdoor Advertising Display

>> 10W 12W 15W 12 Volt LED Panel Light Full Surface Mounted Downlight

>> 100% Lyocell Stripe Yarn Dyed Light Weight Fabric 60X60 124X90 58/59"

>> Auto Ultrasonic Zipper Film Sealing and Hole Punching Machinery Zipper Machinery

>> Powerful Electric Light Cargo Load Tricycle of 800 Kg Load Capacity

>> Automatic Tool Change 5X10 CNC Router for Woodworking for Furniture Cabinets Making

>> Colorful 3-Strand PP Rope Marine Mooring Polypropylene/PE /Nylon/ Polyester Rope for Fishing Net

>> Large Capacity Automatic Four Nozzles High Accuracy Weighing Down and Cotton Filling Machine (RM4-16D)

>> USB 3.0 Printer Cable, 1.5m Length

>> Plastic Box Injection Molding Machine Plastic Injection Mold

>> car spare parts rear wheel bearing hub assembly for ford explorer 3L2Z-1109-AA

>> 1050 Aluminum Sheet for Signs

>> High quality wholesale MALIBU car rear shock absorber for Chevrolet/Buick 13319750 13310727 22834091

>> Vegan Chameleon Pigments Watercolor Eyeshadow Duo Chrome Pigments

>> DDP DDU Shipping to UAE Fast Air Freight Forwarder China Logistics Agent

>> Car Parts Variable Engine Oil Control Timing Valve Vvt Solenoid 55567050 for Chevrolet

>> Cheap Price Attachable 36V 350W Electric Handcycle on Sale

>> GAPV High quality For Toyota Yaris vios 2017 2018 2019 Turning Signal Car LED DRL LED Daytime Running Light OEM 81440-0D050

>> 18W 300mm 90~265V 50/60Hz T5 LED Tube

>> High speed plastic bottle servo motor blow moulding machine

>> After market S Class Condenser Air Con Cooling Condenser For Mercedes Benz 2215010154

>> OGM series Diesel Fuel Flow Meter Liquid Flowmeter Electronic Water Meter

>> Shower Double Layer Bubble Foam Natural Sisal Soap Bags Soap Exfoliating Bags Soap Mesh Bag

>> Chinese Factory Slant Bed CNC Cutting Turning Machining Lathe Tck36A

>> Z3080X20 Deep Drill Metal Machine Tool Hydraulic Radial Drilling Machine on Sale

>> Hot selling high quality outdoor decoration stainless steel rope wire mesh

>> Factory Direct Sale Small Scrap Metal Single Shaft Shredder Machine for Iron and Steel Mini Plastic Bottle Aluminum Can Shredder

>> CNC Milling Machine Ceter 3axis Fanuc

>> 2FT T8 LED Grow Light Full Spectrum High Output Linkable Design Plant Lights for Indoor Plants

>> Big Bore Heavy Duty Pipe Threading Lathe Pipe Screw-Cutting Lathe Machine