LDPE PP Woven/Sack Bag Waste Plastic Washing Recycling Drying Line

Basic Info.

Material Processed

Plastic Bottle

Plastic Type

PE

Screw

Double-Screw

Automation

Automation

Computerized

Computerized

Certification

CE, Meet UL ISO

Place of Origin

China

Application

HDPE Bottle, PE Bottle

Motor Power

100-350kw

Showroom Location

Egypt, United States, Brazil, Pakistan

Core Components

PLC, Engine, Bearing, Motor, Gear

Heating Pipe

Electricity Heating Pipe

Transport Package

Packing by Wood

Specification

50*4*4m

Trademark

Polytec

Origin

Zhangjiagang, China

HS Code

8477800000

Packaging & Delivery

Package Size

1.00cm * 1.00cm * 1.00cm

Package Gross Weight

1.000kg

Product Description

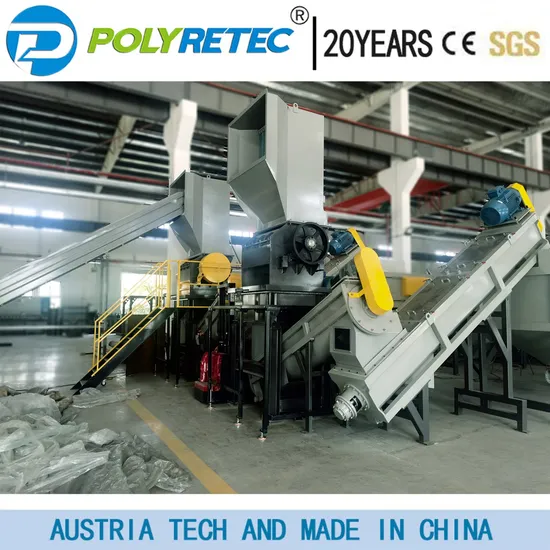

Product DescriptionSoft plastic bag washing line

01 - Project introduction

Plastic bag is a valuable secondary resource in the plastics recycling market. Recycled bag can be used to produce wide range of products.

For the bag recycling industry, POLYTEC offer a series of well-developed recycling lines for the efficient recycling of all kinds of bags.

02 - Project introduction

POLYTEC persistently adheres to the design concept of "SMART RECYCLING, HIGH-VALUE PLASTICS", concentrating on economy, practicality, and stable performance, continuing to seek breakthroughs in equipment production capacity, power consumption, water consumption, finished product loss rate, and degree of automation. In recent years, by actively absorbing Europe's valuable experience in film (PE) and woven bag (PP) recycling, and combined with our company's many years of waste plastic recycling experience, we manufactured updated PP/PE floating washing line to realize efficient coarse crushing, fine crushing, washing and discharging.

03- Processing object

Jumbo bag: industrial waste jumbo bags, imported baled jumbo bags etc.; Woven bag/Ton bag: Chemical raw material bags, feed additive bags, metallurgical powder bags, ore powder bags etc. Impurities: mainly small amount of contained material residue, a small amount of oil residue, sediment, the cotton thread which at the strap of the jumbo/ton bag etc.; Sewage components: mainly muddy water, bottom sedimentation, a small amount of plastic debris and floating objects, etc. Sewage Treatment requirements: After four-stage filtration, the sewage can be directly discharged or recycled again.

04 - Processing Flow

The bag washing line equipped crushing, washing, and drying units, which allows to process different dirty levels of materials, from shopping bags, vest bags, inner packaging bags, outer packaging bags to jumbo bag, woven bag, etc,

The washed bags are fed into a squeezer to remove the moisture. Having a plastic squeeze dryer is a must to dehydrate the washed bag, reduce the volume of recycled materials, and further refine the essence of final plastic pellets.

05 - Technical characteristics

| Model | Input capacity (kg/h) | Required Area (m2) | Installation power (KW) | Required compressed air (m3/min) | Average consumption (ton) |

| PP500 | 500 | 200 | 140-225 | 0.5 | E: 67-225kw W: 2-6.5t |

| PP1000 | 1000 | 400 | 270-320 | 0.5 | |

| PP1500 | 1500 | 1000 | 500-570 | 0.8 |

06 - Advantages

1. Shredding system is designed specifically for film materials to create a uniform particle size which is easy for washing and drying. 2. High speed washing system optimized according to the specific material type liberates and separates contamination from film flakes. 3. Under water force-washing paddles in our washing tanks maximize the washing efficiency. 4. Mechanical (centrifugal and squeezing) and thermal drying systems control the moisture content of the finished product. 5. At < 5% moisture the material is suitable for high quality pelletizing. 6. Shredding, high speed washing and drying stages are optimized to avoid over processing which can cause material loss (fines creation). 7. Intelligent system automation ensures that components actions are sequenced and monitored. 8. Integrated systems to go from field to pellet. 07.Unit Introduction:

08.Project cases :

ABOUT US

| Suzhou Polytec Machine Co LTD focuses on the R&D and manufacturing of complete set of waste plastic recycling and processing systems and has provided services to customers in more than 30 countries through high-quality customized solutions, professional real-time technology and after-sales service. POLYTEC is currently working on four directions: 1. Waste plastic cleaning and classification: waste plastic films, bags, barrels, bottles, etc. are broken and cleaned, and plastics of different materials are separated, which are directly used in downstream industries such as recycled plastic granulation; 2. Recycled granulation of waste plastics: recycled granulation after cleaning of factory materials and post-consumer plastics; 3. Development of key machinery for recycling and recycling: R&D and manufacturing of key models for different materials in different industries, and provide key equipment for various process routes; 4. Waste electronic waste treatment: Provide system-wide process design and development and reuse for the growing consumer electronic products. 5. Design and implementation of project engineering: Our company provides guidance on plant design layout in the early stage of the project, and the overall installation of on-site water and electricity |

| Technology: |

| With Austrian Technology & Made in China Complete machine range: waste plastic washing line and pelletizing line Use our own factories to manufacture waste plastic recycling machines With many patents |

| Team: |

| Our CEO with over 20 years' rich experience in international trade business Our staff have over 15 years' rich experience in machine R & D, manufacturing and testing field, assembling workers with over 5 years' rich experience in our industry |

| Certificates: |

| With CE certificate Can meet UL/ISO/ standards With more than 15 national patents. |

| Profession: |

| English, French are available Customized machines are welcomed Instructions and other files are equipped The machine supports the third-party inspection for quality assurance |

| Services: |

| Perfect pre-sales service and after-sales service Support machine testing by using customer's raw material After--sales machine testing service is available. |

| Sample projects: |

| We already provided machines for customers over 30 countries, such as America, Mexico and so on. Some projects can be visited for reference. |

>> 4mm Honeycomb Cardboard Machine for High Quality Food Packaging Production

>> Yinghe Laser CO2 1390 Laser Engraver

>> Fitness Tights Men′s Sports T-Shirt Quick Dry Running Training Suit Short Sleeve Shirt

>> Best Selling Disposable Laparoscopic Endoscopic Linear Cutter Stapler with CE

>> Wholesale No Drawstring Plain Short Sleeve Jumpers Men's Half Zip Hoodies with Hood

>> Electric Vegetable Transportation Tricycle From The Farm to Markets

>> Weishu no needle needle free electromagnetic water mesotherapy skin whitening injection device

>> 200kw Spring Hydraulic Compound Mineral Machine Rock/Impact/Hammer/Limestone/Mobile/Stone/Jaw Vertical Shaft Crusher for Quarry Concrete Granite

>> Wholesale Cheap High Quality Wireless Door Bell for Building

>> Premium Elmak Crane Jib Section

>> ASTM F2029 Laboratory Heat Sealer Plastic Wrap Film Heat Seal Tester Equipment

>> 100% Solids Clear Epoxy Resin Coating Colorful Metallic Epoxy Floor Coating for Garage

>> Network Modular 8P8C Plug Cat.5 Cat.5E RJ45 Connectors

>> hull black xinjiang walnuts for Peru India Vietnam USA France Philippines Nepal Morocco Bangladesh Canada

>> Solar Panel Connector Waterproof IP65 Cable Connector Male Female Wire Adapter

>> Auto Body Parts auto front bumper grille used 53102-06020 for toyota

>> Disposable Non-Woven Fabric Mask with 99% Filter Paper, Ultra-Soft Smooth Matte Mask, Activated Carbon Mask

>> Paibee Wholesales Glass Charger 13′′ Plate Wedding Decoration Home

>> Original Textile Open End C&U 72-6 Rotors with T34DN Cup 85000rpm

>> China Easy Operation Automatic Gear Type Tapping Machine

>> Factory Price Children Toys Colorful Scooter Toys Outdoor Playing Toys Anti-Slip Handlebars Rear Foot Brake Height Adjustment High-quality Kids Scooter Toys

>> Mstar High Speed 4FT 1500 Size Veneer Peeling Machine Woodworking Machine

>> Agricultural Farming Adjustable Tilling Width Till Cultivator Electric Rotary Tiller Cultivator

>> C Type Automatic Rubber Vulcanization Press Machinery

>> Automatic Dumpling Machine for Efficient Food Production

>> DC pass to LNB hd digital satellite finder

>> Super Large Container Blowing Extruder Chemical 2000L IBC Tank Blow Molding Machine

>> New Design Baby Travel Suitcase Baby Sliding Car Baby Twist Car

>> 10-1000kw Container Type Open Type Continuous Running Gas Biogas Biomass LPG Generator

>> Leibin Electric Golf Cart ATV off-Road Lift 72V120ah Lithium Battery 4 Seats