Industrial Grade CNC Machinery Grinder

| US$20,000.00-60,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

DF46/75-500

Application

Metal

Process Usage

Metal-Cutting CNC Machine Tools, CNC Non-Conventional Machine Tools, Metal-Forming CNC Machine Tools

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.03~0.04(mm)

Performance Classification

High-End CNC Machine Tools

Certification

CE

Condition

New

Model No.

Df46/75-500

Processing Material

Hard Metals, Soft Metals, Alloys, Steel Structure

X / Z / Y Axis Travel

500 / 600 / 100

X2 / Z2 / Y2 Axis Travel

400 / 650 / 300

Tool Magazine

12t

Spindle Taper

Bmt45

X / Z / Y Axis Servo Motor

3.0 /2.2 / 2.0

X2/ Z2 / Y2 Axis Servo Motor

1.8 / 2.0 / 1.0

Transport Package

Plywood Case

Specification

2700 X 1950 X 2050mm

Trademark

LT

Origin

China

HS Code

8457101000

Product Description

High Speed Dual Spindle CNC Metal Processing Machinery Grinding Milling Machine: Unleash unparalleled efficiency and precision with our state-of-the-art Industrial Grade CNC Machinery Grinder. Engineered for superior performance, this advanced machine seamlessly integrates high-speed grinding and milling capabilities. Perfectly designed to meet the rigorous demands of modern metal processing, it ensures exceptional quality and consistency in every project. Elevate your production processes with our cutting-edge technology.Product Description

Our cutting-edge, industrial-grade CNC Machinery Grinder is a marvel of modern engineering, featuring dual spindle technology that revolutionizes efficiency and precision. This advanced machine boasts two independent spindles, enabling unparalleled productivity in a variety of demanding sectors. Widely revered in aerospace, automotive, and textile industries, our two spindle CNC machine meets and exceeds the stringent demands for speed and accuracy required in these fields. Experience the pinnacle of machining excellence with our state-of-the-art CNC solutions.

Product Parameters

| Project | Name | specification | Unit |

| Process range | Max bed rotating diameter | Φ400 | mm |

| Maximum processing length | 500 | mm | |

| Maximum processing diameter (shafts) | Φ75 Φ45 | mm | |

| Maximum processing diameter (disk type) | Φ400 | mm | |

| X / Z / Y X2 / Z2 / Y2 | X / Z / Y axis travel | 500 / 600 / 100 | mm |

| X2 / Z2 / Y2 Axis Travel | 400 / 650 / 300 | mm | |

| Repetition accuracy X / Z / Y | ±0.003 | mm | |

| Position accuracy | ±0.005 | mm | |

| Movement | X / Z / Y | 30/30/28 | mm |

| X2 / Z2 / Y2 | 24/30/18 | mm | |

| Screwdriver | X / Z / Y | 32/36/40 | mm |

| X2/Y2/Z2 | 32/33/25 | mm | |

| Rails | X / Z / Y | 35/35/30 | mm |

| X2/Y2/Z2 | 30/35/25 | mm | |

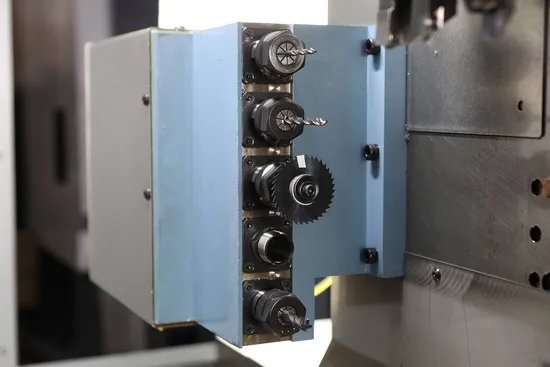

| Turrets | Turrets | 12T | |

| Turning tool specifications | 25X25(rectangular) | ||

| Bore cutter specification | Φ25 Φ32 | mm | |

| Spindle | Positive/sub spindle nose form | A-26(75) / A2-5(45 ) - A2-4(36) | / |

| Through-hole diameter of main/sub spindle | Φ75(Φ45) / Φ36 | mm | |

| Positive/sub spindle speed | 3500-4500 / 5000 | rpm | |

| Control System | Positive/sub spindle motor power (electric spindle) | 18.5 / 7.5 | kw |

| X / Z / Y axis servo motor | 3.0 /2.2 / 2.0 | kw | |

| X2/ Z2 / Y2 axis servo motor | 1.8 / 2.0 / 1.0 | kw | |

| Turret power head milling cutter motor/backside shaft end motor | 2.0 / 1.0 | kw | |

| Dimension | Length/Width/Height | 2700 X 1950 X 2050 | mm |

| Heavy | 4.9 | T |

Detailed Photos

• Simultaneous machining of two workpieces: The dual spindle CNC machine offers the remarkable ability to machine two workpieces simultaneously, significantly enhancing machining efficiency.

• High-precision machining: This sophisticated machine tool is designed to meet stringent machining precision standards, delivering exceptionally fine cutting capabilities. It excels in achieving internal and external precision, roundness, coaxiality, and more.

• Multiple processes: Capable of executing a multitude of complex processing procedures, this machine handles a variety of radial and axial cutting, drilling, tapping, hobbing, scribing, drawing, and beyond, all in one go.

•Precision Spindle with High Precision, High Performance, and High Stability

•The spindle set is manufactured in Taiwan. The tool grab system on the main shaft utilizes a butterfly spring mechanism, applying tension to the pull nail of the tool handle through the four-jaw broach mechanism. This ensures an immaculate fit with the main shaft's taper hole for optimal tool grip.

•Low inertia spindle motor: Featuring short acceleration times, this motor boosts tapping speed and quality. The direct drive spindle, equipped with orientation functionality, enhances operational efficiency.

•

Lead Screw

Utilizing C3 grade precision screws with a pre-tensioning design across all three axes, this configuration effectively mitigates temperature rise. This design choice ensures prolonged operational life and consistent repeated positioning accuracy.•

Line Track

Employing P-grade roller type rails across all three axes, this system achieves unparalleled rigidity and high load capacity in four directions through the seamless contact between the rolling elements and the sliding rail line.

Anoher Advantages

Experience Stellar Processing Conditions and an Impeccable Production Environment

Our suite of imported machinery, including horizontal and vertical machining centers, CNC boring machines (with rotating tables), and gantry guideway grinding machines, guarantees unparalleled workpiece accuracy. This results in significantly improved assembly precision and long-lasting measurement integrity.

Cutting-Edge Detection Techniques We employ laser positioning accuracy tests and optimal corrections, adhering strictly to the rigorous German VDI3411 inspection standards, conducted five times each.

Every machine tool undergoes a stringent processing test before it leaves our factory. This ensures it meets real-world processing challenges head-on, fulfilling all necessary accuracy requirements.

Product sample

• The state-of-the-art CNC machine center seamlessly integrates the powerful functionalities of milling, drilling, and tapping into one sophisticated system.

• Expertly designed for CNC Machining, this versatile equipment effortlessly handles various sizes of metal profiles, including aluminum, steel, copper, as well as non-metal materials.

• Our advanced CNC Vertical Machine Tools are widely embraced across diverse industries, such as 3C electronics, rail transportation, aerospace, and liner module guide rail applications,and many more.

Packaging & Shipping

Professional Team

FAQ

1. What are the Payment Terms?

A: We accept T/T (Telegraphic Transfer). A 40% initial payment is required when placing the order, and the remaining 60% balance payment must be completed before shipment.

2. What are your trade terms?

A: We accommodate various trade terms including FOB (Free on Board), CFR (Cost and Freight), and CIF (Cost, Insurance, and Freight).

3. When is the delivery time?

A: For standard machines, we can have your order ready within 30 days. For specialized machines, the lead time may be longer. You can place your order according to the delivery schedule we provide, and we will offer precise shipping times accordingly.

4. What is your minimum order quantity and warranty?

A: The minimum order quantity is one set, and we offer a one-year warranty for our machines.

5. What is the packaging of the machines?

A: Our machines are standardly packed in sturdy wooden cases to ensure safe and secure transportation.

6. How can I choose the most suitable machines?

A: Please provide your detailed specifications, and we will recommend the best model for your needs. Alternatively, you can select the exact model you prefer.

You can also send us your product drawings, and we will identify the most suitable machines for you.

>> Wholesale Factory Digital Television Smart 43 55 65 75 86 98 105 110 Inch LCD Android LED TV Touch Interactive Flat Panel Display

>> Spt Automatic Trip Hammer Sampler for Soil Test

>> CNC 4 Axis Router for Hard Fines Woods Wood Engraving Machine Engraving Machine CNC Machine Cutter

>> Hot Sale Kids Hand Puppet Making Felt DIY Craft Kit

>> Stainless Steel Woven Net Roll 20 Mesh Metal Wire Window Screen Mesh Filter Screen Mesh for Vent Hole

>> Special Price This Month High Quality Horizontal Vertical Metal Turret Milling Machine

>> Used Qy70K-II 70 Tons Crane Mobile Construction Truck Heavy Machine Truck

>> PP/CPE/SMS Disposable Reinforced/Knitted Surgical Apparel/Medical/ Exam/Operation Isolation Gown

>> Electric Hospital Beds Electric Five-Function Operating Table

>> Wholesale Auto Car Spare Parts For Nissan Timing Chain Tensioner Kit TK9190

>> 300W Imaging Light Profile LED Spot Light

>> High-quality and durable metal grilling net

>> Customized Color and Type Security Container Split Bolt Seal for Transport

>> Happy Car 360 Amusement Rides Happy Swing Fantastar Leswing Happy Le Bar Car

>> 100 Polyester Tricot Knitted Flock Fabric

>> Outdoor Gas Heater with Glass View by LPG for Home and The Commercial

>> Best Price Wheelchair Lift with CE Certificate

>> Movable Single Phase E-Waste CD SSD Laptop Hard Disk Shredding Machine

>> New Design Steam Car Wash

>> MMO tubular anode for cathodic protection Iridium-tantalum coated titanium Disk anodes for cathodic protection

>> Dust-Free LLDPE Waste Plastic Extruder

>> CETC AIS MOB VSA8 PLB

>> 6140 China Flat Bed CNC Lathe Machine

>> CNC High Speed Beam Drilling Line

>> Weighbridge Load Cell Truck Scale Load Cell Weighing Sensor

>> 150mm White Wall Mounted Air Small Exhaust Fan

>> Dtwmac Dtl-60ds Edge Sander for Wood Cabinet Door Side Polishing

>> Factory Supply Cheapest Price Cultivator Machine Cultivators Agricultural Farming Mini Tiller Cultivator

>> Promotion Inflatable Coated Tarpaulin Environmental Protection Outdoor Tarpaulin

>> PLC Intelligent Synchronous Lifting Jack Controlling Hydraulic Oil Cylinder Bridge Construction Large Tonnage