High-Quality Automatic Extrusion Blow Molding Machinery for Making 500ml 1L Pet Olive Corn Oil Bottles

| US$39,000.00-99,000.00 | 1 set (MOQ) |

Basic Info.

Model NO.

FG-4

Raw Material

PET

Making Method of Parison

Extrusion-Blow Molding

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008, QS, GMP

After-sales Service

1 Year

Capacity

6800-7200bph/H

Mold Cavity

4 or 6 or 8

PLC System

Mitsubishi

Air Pressure

30bar

Cooling Water

22L/Min

Total Power

22kw

Dimension

3200mm*1150mm*2200mm

Export Markets

Global

Air System

6.0m3/Min 3.0MPa Air Compressor

Name

Blowing Machine

Rawl Material

Pet

Usage

Bottle

Keywords

Energy Saving and High Speed

Product

Plastic Bottles

Machine Type

Cm-12

Transport Package

Woodbox with Film Wrapped

Specification

3200mm*1150mm*2200mm

Trademark

faygo

Origin

China

HS Code

84778000

Production Capacity

15sets/Month

Packaging & Delivery

Package Size

3300.00cm * 1200.00cm * 2300.00cm

Package Gross Weight

300.000kg

Product Description

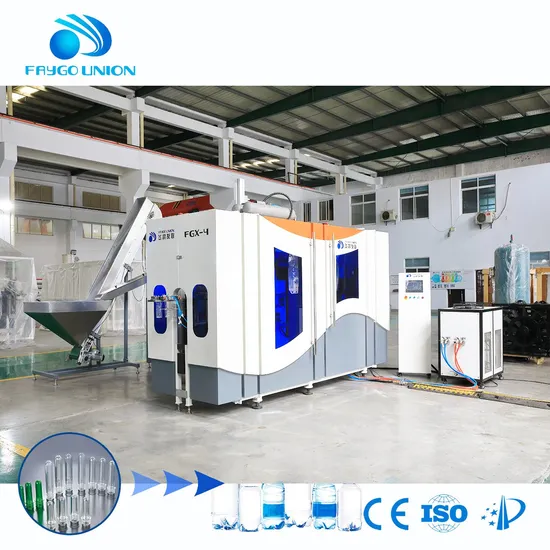

Product DescriptionAutomatic Pet Plastic Bottle Blow Molding / blowing Moulding Machine for making 200ml 250ml 500ml 750ml 1l 2l Water Beverage Juice Bottles

This Bottle Blow Moulding Machine mainly produces PET plastic bottles, pure water, mineral water PET bottles, and beverage bottles.

It is developed totally independently, has our own intellectual property rights, and has obtained more than 13 national patents.

FG series are the most stable two-step automatic stretch blow moulding machine. FG4 serie has four cavities and the maximum capacity of the products is 2L.The capacity can be 6800-8000BPH, It can blow bottles in shapes:Carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET etc.

The Features of this Bottle Blow molding Machine

1).High Automatization

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quanlity:Steady infrared heating system blowing and highly precise blow-mould closing system ensure quality.

4).High Speed:6800BPH(4-cavity)

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

Product Parameters

| Model | FG4 | FG6 | FG8 | Remark | |||

| Mold number(piece) | 4 | 6 | 8 | ||||

| Capacity(BPH) | 6500~8000 | 9000~10000 | 12000~13000 | ||||

| Bottle specification | Max volume(mL) | 2000 | 2000 | 750 | |||

| Max height(mm) | 328 | 328 | 328 | ||||

| Round bottle max diameter(mm) | 105 | 105 | 105 | ||||

| Square bottle max diagonal(mm) | 115 | 115 | 115 | ||||

| Preform specification | Suitable inner bottle neck(mm) | 20--25 | 20--25 | 20--25 | |||

| Max preform length(mm) | 150 | 150 | 150 | ||||

| Electricity | Total installation power(kW) | 51 | 51 | 97 | |||

| Heating oven real power(kW) | 25 | 30 | 45 | ||||

| Voltage/frequency(V/Hz) | 380(50Hz) | 380(50Hz) | 380(50Hz) | ||||

| Compressed air | Pressure(bar) | 30 | 30 | 30 | |||

| Cooling water | Mold water | Pressure(bar) | 4-6 | 4-6 | 4-6 | Water chiller (5HP) | |

| Temperature regulation range(°C) | 6--13 | 6--13 | 6--13 | ||||

| Oven water | Pressure(bar) | 4-6 | 4-6 | 4-6 | Water chiller (5HP) | ||

| Temperature regulation range(°C) | 6-13 | 6-13 | 6-13 | ||||

| Machine specification | Machine dimension(m)(L*W*H) | 3.3X1X2.3 | 4.3X1X2.3 | 4.8X1X2.3 | |||

| Machine weight(Kg) | 3200 | 3800 | 4500 | ||||

Product Details

Servo driving and cam linking blowing section:

The unique cam linking system integrates movement of mold-opening, mold-locking and bottom mold-elevating in one movement.

equipped with high speed servo driving system which greatly shorten the cycle of blowing and increase the capacity.

Small performs distance heating system:

Heater distance in the heating oven is reduced to 38mm, compared with the conventional heating oven it saves more than 30% electricity consumption.

Equipped with the air cycling system and redundant heat discharge system, it ensures the constant temperature of the heating zone.

Efficient and soft perform inlet system:

By rotary and soft preform inlet system, the speed of prefom feeding is ensured meanwhile, the preform neck is well protecte

Modularized design conception:

Adopting modularized design concept, to make it convenient and cost-saving for the maintenance and changing spare parts.

FG Series Optional items:

Exploded bottles ejection unit:

During the blowing process, if the bottle burst, bad bottles can be automatically removed.

This prevents the bad bottles from entering the filling machine.

HP air recovery system:

After the bottle blowing, high-pressure air can be recycled and used again for the pre-blowing and machine physical movement.

Oven and preform temperature detection system:

Detection system detects temperature of oven and the temperature of performs.

When the preform temperature does not reach the set blowing temperature, blowing workstation will alarm, not blown.

Equipped with remote monitoring system:

Engineers in China headquarter can check the data collected and sent by the PLC anytime with the mobile ,feedback will informed to the client's site if something abnormal ,give the machine 24 hour'baby care in the cradle.

Related Products

Company Profile

Jiangsu Faygo Union Machinery is a professional manufacturer of plastic machines.

It occupied an area of 18000 square meters. With years of development, its products covers plastic extrusion lines,

plastic blowing machine, plastic recycling machine, air compressor etc.

Stick to the company idea is making good machine, being good person,

Faygo Plast alwasy provide customers with high quality machines.

Warmly welcome to visit our factory (next to Shanghai)!

FAYGO UNION GROUP has 3 branch factories.

1.FAYGOBLOW which design and make blow molding machine for PET, PE etc. FAYGOBLOW has 5 patents of invention, and 8 patents utility models. FAYGO PET blow molding machine is one of fastest and most energy-efficient design in the world.

2.Second factory is FAYGOPLAST, which make plastic extrusion machinery, including plastic pipe extruding line, plastic profile extruding line. Especially FAYGOPLAST can supply high speed up to 40 m/min PE,PPR pipe line.

3.FAYGO RECYCLING, which research new technology in plastic bottle ,film recycling processing and pelletizing. Now FAYGO RECYCLING can make up to 4000kg/hr. PET bottle washing line, and 2000kg/hr plastic film washing line.

Now FAYGO UNION GROUP has more than 500 customers from different countries, including UK, Spain, Germany, Norway, Switzerland, Italy, Turkey Russia etc. from Europe ,and America, Canada, Mexico, Brazil, Venezuela, Chilly etc from America, and Saudi Arabia, Iran, Syria, India, Thailand, Indonesia etc. from Asia, and many customers from Africa.

Our factory is located in Zhangjiagang city, covers an area of 26,650 square meters. It only takes around two hours driving from SHANGHAI international airport. Welcome to visit our factory, and hope to cooperate with you in the near future.

FAQ

Q: Your company is a transactional company or an industrial manufacture factory?

A: We are an industrial manufacture factory which locates in Zhangjiagang city.

Q: All of your products are made by your self or compacted via purchasing the others?

A: We have independent technical team who focus on making machines, all the products are made by our technical team.

Q: What is the ability of your factory?

A: About 100 lines per month.

Q: Do you have any other services about your products?

A: We have a lot of experience on making projects and specifications for our clients, also we have a fixed service system.

Q: How do you make the quotation for clients?

A: The price depends on quality and performance but the clients should be satisfied first.

>> Sapele mahogany solid wood entrance doors , malaysia wood door

>> Warehouse Storage Heavy Duty Steel Metal Pallet

>> 18V Lithium Battery Power Garden Cultivator Cordless Tiller with Telescopic Tube

>> High Precision Lathe From C6266X2200 Precision Gear Head Lathe

>> High Voltage Epoxy DC Contactor/Relay for Charging or Energy Storage

>> Promotional Different Size Cotton Reusable Grocery Shoulder Bag Free Sample Beach Tote Bag Durable Cotton Canvas Shopping Bag

>> Graphite Square Block Graphite Cube for Heat Exchanger Exothermic Welding

>> OEM ODM Modified Corn Starch Processing Line + Modified Corn Starch Making Machines + Modify Starch Make machine

>> PVC Coated Polyester Fabric Roll (PF-005)

>> 7 / 8 Cable 4,3 - 10 conector di solar de calidad ra - 90 grados

>> 150L Single Double Coil Air Source Hot Water Heater Tank Buffer Tank for Heat Pump

>> Sm200mt Chinese Famous Brand Asphalt Cold Milling Machine for Road Construction for Sale

>> Custom Print Container Blank Kraft Paper Ice Cream Cups Machine with Small Lid for Ice Cream Paper Cups Machine

>> 2024 New Bag Birkinbag Women′s Handbag Kelly Baotou Layer Cowhide Single Shoulder Crossbody

>> New Fully Automatic Machines 5 Zones 2.3mm Independent vacuum Rolling Mattress Pocket Spring Materials

>> 1325 Laser Engraving and Cutting Machinery

>> High Carbon Steel Heavy Cut Sheet Metal Hammer

>> Stone-Coated Steel Roofing Galvalume Steel Coated with Stone Granules

>> Má Quina De Soldadura Lá Ser, Equipo De Soldadura Lá Ser De Metal, Soldadura Lá Ser 3 En 1

>> Adjustable 5 Level Metal Warehouse Rack Office Garage Steel Boltless Shelving

>> Module spare parts 3BSE008510R1 DO810

>> Madly LP580 Hood for Lamborghini Huracan LP580/LP610 P Style Hood

>> Howell 225L Pid Control Forced Air Drying Oven for Laboratory

>> RGB Mini DJ Disco Laser Light Projector USB Rechargeable LED UV Sound Strobe Stage Effect Wedding Xmas Holiday Party Lamp

>> Split Frame Pipe Beveling and Cutting Machine for Industrial Steel Pipe

>> 1600/2400/3200mm CE Approved Hg Wooden Cases Medical Equipment Nonwoven Fabric Making Machine

>> Stainless Steel China Fasteners Nuts and Bolts/Hexagonal Bolts and Nuts/DIN/Unc Carriage Bolt/U Bolt/ Hex Flange Bolt/Anchor Bolt /Eye Bolt/Stud Bolts with Nut

>> Korea′s Best-Selling Factory-Priced Injectable Dermal Filler Sedyfill Breast Enlargement Butt Lift Enhancement Maxy Fill 60cc Mesodermal Breast Enlargement Body

>> 400m Hose Reel Irrigation with Travelling Big Rain Gun

>> Anshi 0.5HP Peripheral Water Pump with Thermal Protector (QB60)