Rbt 5-Axis CNC Milling Machine for Plastics Composites Light Alloys CE Approved

Basic Info.

Model NO.

RB-F10-4057-Z09

Application

Plastics, Composites, Light Alloys, Resin

Process Usage

CNC Non-Conventional Machine Tools

Movement Method

Point to Point Control

Control Method

Closed-Loop Control

Numerical Control

CNC/MNC

Processing Precision

0.01~0.02(mm)

Performance Classification

High-End CNC Machine Tools

Certification

GS, RoHS, ISO 9001

Condition

New

X Axis Effective Stroke

4000mm

Y Axis Effective Stroke

5700mm

Z Axis Effective Stroke

900mm

B-Axis Rotation Angle

+/- 130 Degree

C-Axis Rotation Angle

+/- 540 Degree

X/Y Axis Maximum Speed

50m/Min

Z Axis Maximum Speed

20m/Min

Repeat Accuracy

+/-0.05mm

Voltage

380V

Total Power

13.95kw

Spindle Power

17kw (Customizable)

Frequency

50Hz

Weight

6t

Transport Package

Export Safety Packing (Customized Packing)

Specification

L9000*W6800*H4250mm

Trademark

RBT

Origin

Quanzhou, China

HS Code

84659990

Production Capacity

200set/Month

Packaging & Delivery

Package Size

900.00cm * 680.00cm * 425.00cm

Package Gross Weight

6000.000kg

Product Description

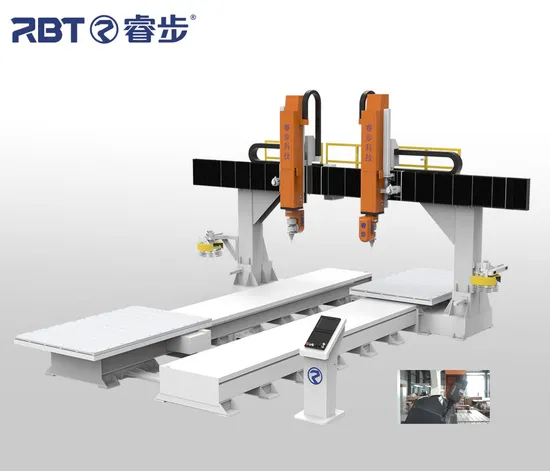

Product DescriptionRbt 5-Axis CNC Milling Machine for Plastics Composites Light Alloys CE Approved

Product Parameters

| No. | items | parameter | No. | items | parameter |

| 1 | product name | FIVE-AXIS CNC MILLING MACHINE WITH TWIN TABLE & HEAD | 9 | Z axis maximum speed | 20m/min |

| 2 | model | RB-F10-4057-Z09 | 10 | Repeat accuracy (within 300mm) | ±0.05mm |

| 3 | X axis effective stroke | 4000mm | 11 | voltage | 380V |

| 4 | Y axis effective stroke | 5700mm | 12 | total power | 19.15-31KW |

| 5 | Z axis effective stroke | 900mm | 13 | spindle power | 5.5-20KW(customizable) |

| 6 | B-axis rotation angle | ±120° | 14 | Frequency | 50HZ |

| 7 | C-axis rotation angle | ±540° | 15 | weight | 5-15T |

| 8 | X/Y axis maximum speed | 35m/min | 16 | size | 9000*6800*4250mm |

Machine details with photos

1. The SYNTEC five-axis linkage CNC system is utilized in this machine, which can process the entire complex surface of the workpiece in one time clamping.

2. Compatible with NC programs generated by various CAD/CAM 3D programming software such as UG and POWERMILL .

3. The milling head has 2 CNC continuous rotary coordinates: the 4th (C) axis and the 5th (B) axis, realizing linkage processing (including milling and hole rolling functions)

4. 8 station auto tool library each side, automatic replacement of 8 different tools, quick replacement of tools and improved production efficiency.

5. Accurate positioning, high processing precision, high efficiency, time saving and labor saving.

6 This machine combines power, speed, and precision, and can be enhanced with various functions such as dust collection, and RTCP.

7. Two worktables can be combined into a group and interlocked with the two processing heads to process large workpieces, greatly improving the processing efficiency of symmetrical parts.

8.Two worktables and heads can also work seperately, which is equivalent to having two five-axis machining centers performing processing operations at the same time.

7.We provide complete and feasible dust collection solutions based on the customer's factory layout. The machine has a reserved dust collection port, which allows for easy installation of a dust collection device.

Machine Application

5 Axis CNC Milling Machine is widely used in: Mold manufacturing, composite material processing, and thick sheet thermoforming processing in industries such as aerospace, rail transit, automotive interior and exterior, sporting goods, medical beauty, white goods, handicrafts, and sanitary ware. Also the processing of aluminum,copper,zinc and other soft metals,aluminum honeycomb,paper honeycomb.

Applicable processing materials:

Composite materials: carbon fiber (PCM/RTM/SMC/LFT, etc.), glass fiber, carbon/carbon, glass fiber reinforced plastic, aramid fiber honeycomb, aluminum honeycomb, honecomb sandwich panel, styrofoam foam, EPS, wood, MDF, plaster, resin, ect.

Thermoformed plastics: ABS, PVC, PC, PP, PS, PE, PET, HDPE, PETG, Acrylic etc.;

Soft metal : aluminum/copper/ zinc, aluminum mold.

Certifications

CE Approved five axis cnc milling machine

Company Profile

Packaging & Shipping

1.Plastic film packaging and put in plywood wooden cases or according to customer's requirements.

2.Shipping : Container transport.

Customer Distribution

>> Genuine Auto Spare Parts for Asia Motor Rocsta K3326 Brake Shoe

>> Modern Oversized Double Glazed Aluminium Sliding Glass Doors

>> Day and Night Vision Binoculars for Sightseeing, Hunting 10 X 50 Factory New Hot Sale Zoom Telescope Cc50

>> Fully Automatic Control System Wood Dry Kiln Timber Drying Chamber

>> Best sale bp machine medical adult child floor stand type mercury aneroid sphygmomanometer

>> Fashion Pull Handles Profile Furniture Cabinet Glass Door Frame Aluminium Alloy Profile

>> Free Warehouse Storage Service Guangzhou Shenzhen China Freight Shipping Agent

>> Stainless Steel/Carbon Steel Water Pipe Flange According to ASME ANSI B16.5 DIN En1092-2 GOST Standard Blind /Slip on/Weld Neck Flange Manufacturer 2024

>> Hc-B094H Steel Mobile Laminar Air Flow Cabinet Workbench Vertical Clean Bench for Laboratory

>> Cummins 20-2000kVA Diesel Generator with Global Warranty

>> Taiwan Quality 4 Axis Metal CNC Milling Machine Price (BL-V8/V11)

>> Modsonic Ultrasonic Thickness Gauge Price

>> Vacuum Hopper Hopper Automatic Extrusion Blowing Blow Molding Moulding Machine

>> 4X4 Electric Winch Wireless Recovery 12V 13500lb / 6125kg with Synthetic Rope

>> Benzin Earth Auger (52CC, 2.2KW)

>> 2024 Automatic High Speed 3 Axis Milling Machine Vertical Cutting Machine Vmc1160

>> Cheap Pillar Machine for Precision Drilling with 470*360mm Base and 510mm Swing

>> High Quality Electric Sheep Wool Hair Clipper Machine with Comb

>> Hico 4 Channel H265 Real Time Full HD 1080P Hybrid 6-in-1 DVR Recorder with 2 HDD and Alarm WiFi 3G Function

>> Table Mini Drill Press for Detailed and Intricate Woodworking Projects

>> China Car Accessories Power Tail Gate Electric Tailgate For Land Rover Discovery 5 2017+ Rear Trunk Back Door

>> New Luxury OEM business gold case watch casual leather strap wrist watches men luxury brand automatic

>> Pet Water Bottle PP Bottle One Step Injection Stretch Blow Molding Machine

>> Puppy Durable Squeaky Dog Chew Toy

>> Fujitang - Factory Wholesale Herbal Flower Tea Blend Healthy Tea Chrysanthemum Cassia Seed Bright Eye Tea

>> Fenetres en pvc sashless double hung window double hung windows 24 x 66 finestra scorrevole verticale prezzo WEIKA

>> CE Certificate Full Size Bunk Bed for Adults Steel Double Bed

>> V Mhj Chemical Industrial Coal Powder Mixer/Mixing Equipment/Blending Machine

>> Type 4/5/6 Chemical Protective Coverall with Elasticated Hood Anti-Static Breathable Disposable Coverall

>> Fly Ash AAC Block Production Line, Keda Suremaker AAC Plant