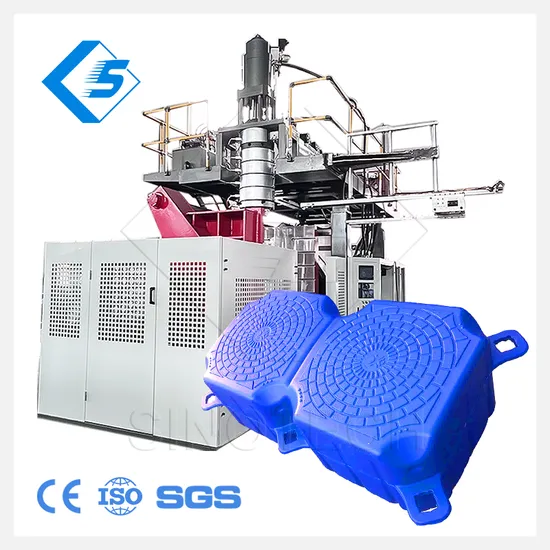

Auomatic Plastic Floating Pontoon Dock Blow Molding Machines with High Efficient

Basic Info.

Model NO.

STD-90

Raw Material

PE PP HDPE

Making Method of Parison

Extrusion-Blow Molding

Automation

Automatic

Computerized

Computerized

Certification

CE, ISO9001:2008

After-sales Service

Commissioning and Trainingengineer Available

Voltage

Customization

Logo

Customization

Outer Packing

Customization

Pattern

Customization

Transport Package

Wooden Case or Film Wrapping

Specification

9000*6500*7800mm

Trademark

SINOTECH

Origin

China

HS Code

8477401000

Production Capacity

1000 Sets Per Year

Product Description

Auomatic Plastic Floating Pontoon Dock Blow Molding Machines with High EfficientProduct Description

Advantages:

1. The temperature controlled by seimens PLC, the extruder stops automatically if the temperature is down because of heater or thermocouples damaged.

2. There is die head pressure testing in the diehead. The PLC shots down the extruders if the pressure inside the die head is too high.

3. The extruders have covers for keeping the temperature, so can make the heating time short

4. The temperature are controled by seimens brand.

5. The extrusion motor is seimens brand.

6. The inverter is seimens brand.

7. More protection in control system.

Product Parameters

| Technical Specification | |||

| Specifications | STD-80 series | STD-90 series | |

| Material | PP PE ABS | PP PE ABS | |

| Max. Container capacity | L | 30 | 60 |

| Output (dry cycle) | Pc/hr | 360 | 360 |

| Machine diameter(L*W*H) | M | 4.7*2.6*4 | 5.7*2.6*4 |

| Total weight | T | 12 | 13 |

| Clamping system | |||

| Clamping force | KN | 200 | 300 |

| Platen opening stroke | mm | 350-850 | 450-1050 |

| Platen size(W*H) | mm | 750*860 | 960*980 |

| Max.mold size(W*H) | mm | 520*1000 | 700*1200 |

| Mold thickness | mm | 360-420 | 460-600 |

| Power | |||

| Max. drive | KW | 67 | 74 |

| Total power | KW | 82 | 89 |

| Fan power for screw | KW | 0.5 | 0.5 |

| Air pressure | Mpa | 1 | 1 |

| Air consumption | m³/min | 0.8 | 0.8 |

| Average energy consumption | KW | 38 | 40 |

| Extruder system | |||

| Screw diameter | mm | 80 | 90 |

| Screw L/D radio | L/D | 24 | 24 |

| Melting capacity | Kg/hr | 120 | 130 |

| Number of heating zone | Zone | 4 | 4 |

| Extruder heating power | KW | 21.4 | 21.4 |

| Extruder driving power | KW | 30 | 37 |

| Accumulator head | |||

| Number of heating zone | Zone | 4 | 4 |

| Power of die heating | KW | 21.3 | 21.3 |

| Max.die-pin diameter | mm | 250 | 350 |

| Accumulator capacity | L | 5 | 6.6 |

Application

Detailed Photos

Total Machine Control System

1.The control system is simple but humanized pages easy for operation.

2.100 point parison thickness controller & profile eddition.

3. Production technics and parameter saving for 20 moulds.

4. Professional engineer setting pages for problem diagnosis.

5.Short-cut key board & emergency stop for safety production.

6. Aluminum cantilever operation box and easy adjustment.

7. Remote technical support & program updating.

Die head system

1. Accumulator die head.

2. Temperature control: automatic temperature control module.

3. The max die pin of extrusion is 600mm.

Mould Platen

1. Latest Euro style toggle type clamping system.

2. Bigger platen size capable to carriage more bigger moulds.

3. Stronger clamping force can make the blow molding item bottle joint line finishing smoother.

Automatic Labor Arm

1. It is a necessary parts for blow molding machine to ensure the workers operation safe.

2. Labor saving, easy operation, high production efficiency.

Drum Mould

1. Reasonable cold water runner design for heat transmission.

2. Cutting blade length& flatness for scraps easy removing.

3. Parison over-flow groove depth equal to product weight.

4. Suitable water inlet& outlet position for easy production.

5. precise cold shrinkage calculation to insure filling volume.

6. Multi-functional selection for mould action requirements.

Blowing System

1. Bowing stand adapt to YUKEN, direction valve, using hydraylic drive.

2. Blow rod can optional equipped quick exhaust function.

3.Match non-contact induction switch, ensure accuracy of positioning.

4. Optional air rotating rod, in order to machining tntenal thread.

5. Optional equipped with widen guide rod(wait water cooling), widen the parison.

Extrusion System

1. Screw designed specially based on working quality of material. Diameter of screw: φ120mm, L/D30/1

2. Material of screw: High quality nitriding steel 38CrMoAlA, with nitriding surface HV≥800, brittleness≤2.

3. Material of barrel: High quality nitriding steel 38CrMoAlA, with nitriding surface HV ≥ 900, brittleness ≤2.

4. Drive mode:AC motor + Hard gear surface decelerator.

Air Cooling Fan

1. Air cooling fan guaranteed constant temperature for screw.

Gear Box

1. Frequency conversion speed regulation& Alloy steel hardened gear box.

2. Table speed regulation, energy saving, low noise, durable.

Hydraulic system

1. The main hydraulic system adopts to Japan YUKEN and SUMITOMO hydraulic valves and servo pump, precise pressure of proportion, flow control, quick actions, longer working life.

2. Hydraulic motor available to upgrade to servo drive energy saving, low noise& increase working life of hydraulic units.

Electric control system

1. Japan Mitsubishi PLC system, with Mitsubishi temperature control module.

2. Weinview Touch Screen to easily set and change communication, parameter, image display with

self-diagnose.

3. Japan Mitsubishi inverter provide stable and efficient extruding process.

4. Other main electrical components are from wolrd-famous brands such as OMRON, LG and etc.

Workshop Production

Packaging & Shipping

Company Profile

Certifications

FAQ:

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's the advantage of SINOTECH? We provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipments for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time.

>> High-Performance 3000W Stainless Steel CNC Laser Cutter for Sheet Metal

>> Wall Mounted Greenhouse Poultry Farm Industrial Kitchen Motor Exhaust Fan

>> Premium Silk Feel Transfer Printing Fabric for Stylish Home Wear

>> Custom 3D Shape Pillow Velvet Throw Sofa Cushion Decoration Pillow Stuffed Toys

>> New style chinese top brand customized arched exterior doors with glass soundproof design Aluminum door

>> Taijia liquid ultrasonic flow meters online river water ultrasonic flow meter Flange ultrasonic flowmeter

>> Promotional Metal Craft Gifts Custom Soft Hard Enamel Metal Badges Lapel Pins

>> factory price carbon peeling beauty machine for rejuvenation hollywood peel beauty machine

>> Ep Alkali-Resisting Polyester Rubber Conveyor Belt

>> Green and Environmentally Friendly PP Hollow Sheet

>> For 2005-2016 Hot sale Auto Parts Power Steering Pump 5L 44320-0K020 For HILUX

>> 7% Price off High Quality Cutting Machines Laser / Economic Fiber Laser Cutting Machine

>> Your Own Logo Printed 100% Cotton Thick Fleece Hoodies Winter Men Hoody Pullover Hoodies For men

>> High accuracy automatic weighing triangle tea bag packaging machine pyramid tea bag envelope packaging machine

>> top quality Waterproof Double Glazed Casement upvc Windows Tilt And Turn Window

>> 5 Axis CNC Milling Machine with Fanuc System for Heavy Toilet-Bowl Structures

>> Ict Fully Automatic Online Squeegees SMT Stencil Screen Printing Machine PCB SMD Placement Solder Paste Printer

>> Double Triple Glazed Cladding Exterior Facade Unitized Stick Frame Spider System Price Design Aluminium Glass Curtain Wall

>> Cat Food Machine Line Dry Food for Dogs and Cats Full Production Line Dog Food Make Machine

>> Siemens 1FK7105-2AF71-1QA0

>> Womens Thong Flat Sandals Casual Beaded Comfortable Slip on Esg13402

>> Wholesale Sheet Metal Stainless Steel Aluminium Hydraulic CNC Press Brake Bending Machine 63t/1600mm

>> China Factory Lathe Stand Lathe Turning Tools

>> 2025 Hbking New Design Hot Selling Glass Smoking Water Pipe

>> 750ml Glass Grape Wine Bottles Light Weight 410g Antique Green Bordeaux Bottle

>> Mini Digger Excavator 1.5 Ton Construction Backhoe Garden Household Farm Greenhouse Excavator

>> Wld6200 Economic Auto Bus Truck Spray Paint Booth for Sale/Downdraft Infrared Car Spraying Oven CE/Automotive Baking Room Painting Cabin/Paint Camera/Booth

>> Glt500A Instock 30-500m Steel Tape Battery Deep Well Underground Water Level Meter

>> Eco-Friendly PTFE, Seal Tape for Sustainable Plumbing Solutions

>> New Technical New Design Face Mask Making Machine