Nonwoven Triangular Felting Needles for Needle Punching Machine

| US$0.02-0.07 | 10,000 Pieces (MOQ) |

Basic Info.

Model NO.

CZ-01

Automatic Grade

Automatic

Certification

CE, ISO9001: 2000

Customized

Customized

Condition

New

After-sales Service

Installation and Training

Suitable

Geotextiles or Other Needle Punching Products

Control

PLC Touch Screen or Button

Type

Nonwoven Textile Machine

Speed

High Speed, Middle Speed Customerized

Use

Felt, Geotextile, Synthetic Leather Substrate PRO

Fuction

Make Geotextile Fabric From Polyester Fiber

Key Words

Nonwoven Polyester Geotextile Fabric Machine,

Key

High Speed Needle Loom

Usage

Felt Making Machine

Model

Needle Loom Machine Felt Making Machine

New

CE Needle Punching Machine High Production Efficie

Voltage

380V, 220V, 440V by Order

Motor, Invertor

World Famous Brand

Brand

Lebon

Ranking

Top Manufacture

Transport Package

Export Standard

Specification

2-9.5meter customerized

Trademark

Lebon

Origin

China

HS Code

8448519000

Production Capacity

100-1000kg/H Customerized

Packaging & Delivery

Package Size

50.00cm * 50.00cm * 50.00cm

Package Gross Weight

15.000kg

Product Description

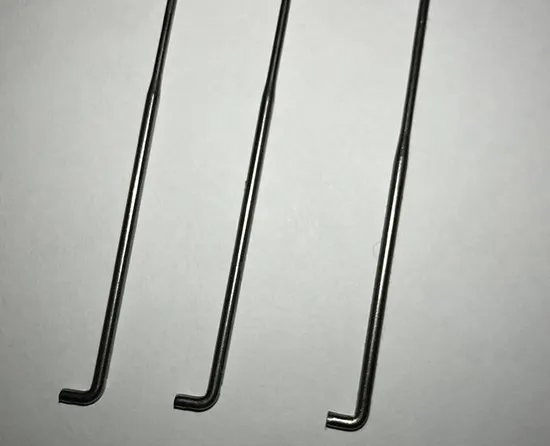

Nonwoven Non-woven Needles for needle punching loom machineFunction

The needle is for the line used to make nonwoven geotextile fabric materials from polyester fiber or PP staple fiber by needle punching machines.

Triangular needle is widely used in geotextile, filter cloth, artificial leather, disposable carpet,paper making blanket,handmade wool,cotton, automobile interior decoration and other industries. it's fit on non-woven machine and needle loom. It has many different types.

Applications:

Needle punching machine line technology process is the very common and prevailing process in the nonwoven industrial.

With diverse machine combination and designs, needle punch production line is applicable for producing various felt, carpet, geotextile, shoe lining, filtration material, substrate layer for synthetic leather and asphalt felt, and other hundreds of innovative nonwoven products.

Geotextiles Production Line can make all kinds of needle punching geotextiles or other needle punching products. This needle punching machine production line can have additions such as batt and/ or felt drafters. Needle looms of diffrent needle types and/ or densities can be used dependent on end use of product.

1. High capacity: up to 1000kg/h

2. This machine line can process 100% long length fiber up to 120mm

3. Enclosed chamer to maintain a negative pressure which can control the airflow properly.

4.Enclosed cover for proper protection and easy maintenance

Technical Parameter:

| Machine width: | 1500-8000mm |

| Needle density: | 4000-7000s/m |

| Needle frequency: | 100-700RPM for middle speed,1000-1500RPM for high speed |

| Needle stroke: | 30-60mm |

| Capacity: | 100kg/h-1000kg/h |

| Available raw material: | PP, PET, Polymide, fiberglass, Carbon fiber, Cotton, Jute, etc |

>> China Supply Bulk Talcum Powder

>> Good Wear Resistance PVC Rod POM Bar PE Round Bar Mc Nylon Rods

>> 2 Burner Induction Cooker Built-in Style Save Space for Restaurant Commercial Used

>> Lyocell Fiber Vortex Spinning MVS 13s Textile Raw Material Yarn

>> Mobile Hydraulic Concrete Placing Boom Flexible Conveying Machinery Placing Radius Hyg13/15/17/19/21/23m

>> Disco DJ Wedding Lighting SD Control 8*8 Pixels Digital LED Dance Floor

>> Pandora 16/20L Knapsack Electric Battery Agricultural Machinery Hand Sprayer Garden Tool Pump

>> Power Hammer Customization Electric Cordless Rotary Hammer Experts

>> Rock Impact Crusher Aggregate Basalt Crushing Plant Stone Crushing Machine

>> Poultry Equipment Chicken Feeding Line

>> Holding Cabinet Banquet Cart Truck Single Door Mobile Electric Food Warmer Cabinet with 11 Layers CE

>> Manufacturer CE Industry Plastic Crusher Pipes PP/PE Lump Block Shredder Bottle Recycling Line Crushing Machines for Sale

>> 10X3m Inflatable Bungee Run Game, 2 Players Bungee Run

>> Ultra High Molecular Weight Polyethylene Sheet

>> Durable Rtk 1408 Channels Imu Survey Chc X6 B5 Gnss Chcnav I73-Ibase

>> Expandable Polystyrene/ EPS Polystyrene Granules /EPS Foam Beads

>> Bentley 3500/46M 3500/46 3500 System Mechanical Protection System Module 3500-46M

>> TM-8810 Metal Thickness Gauge Digital Ultrasonic Thickness Gauge Pipe Thickness Gauge

>> Custom High Quality Portable Eco - friendly Disposable Natural Bamboo Tensoge Chopsticks

>> Multifunctional Diesel Hammer Mill Scrap Metal Crusher for Processing Metal

>> 100% ABU Garcia Max X Lightweight Graphite Body Spinning Fishing Reels

>> Infrared Thermometer Gun for Oil, Water, Industrial Grade

>> Sinotruk HOWO A7 Truck Shacman Weichai Gearbox Parts Wiper Motor 81264016143

>> STPP(SODIUM TRIPOLYPHOSPHATE FG)/ 7758-29-4 sodium triphosphate

>> 52cc 2.2kw Powerful Gasoline Ground Driller

>> Home Appliances Decorative Modern Design E26/E27 Base Ceiling Fan Light

>> skmei 1839 Men Quartz Watches Top Brand Luxury Leather steel Strap Male Men's Watch Sports Watches

>> hard candy machine hard candy forming machine

>> New Genuine B Class W245 Folding Mirror Assy Side Rearview Mirror Assembly 1698101376

>> Highly Concentrated Epoxy Resin Dye for Jewelry DIY Jewelry Making, Craft