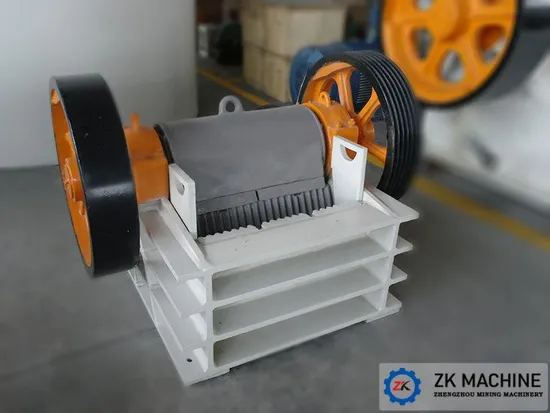

Mineral Crushing Machine Limestone Jaw Crusher

| US$35,000.00-80,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

Various Model

Cutter Material

High-Speed Steel

Drive

Electric

Feed Size

150mm-299mm

Jaw Plate Material

Carbon Steel

Object

Basalt, Copper Ore, Stone

Installation

Under Our Engineer′s Guide

Certificate

ISO9001, ISO14000, CE

Application

Mining

Factory Established

1956

Condition

New

After Sale Service

We Offer

Design

We Offer

Warranty Period

1 Year

Experience

More Than 50 Years

Output

10-15 M3/H

Type

Jaw Crusher

Principle

Fixed Culling

Finished Surface

Cut off Tool

Compressive Strength (for Crushing)

250-300MPa

Tongs′ Features

Dedicated Tongs

Transport Package

Export Standard Package

Specification

ISO9001, ISO14000, CE

Trademark

ZK

Origin

Zhengzhou, China

Production Capacity

50 Set/Sets Per Month

Product Description

HENAN ZHENGZHOU MINING MACHINERY CO., LTD was founded in 1956, after more than half a century of development, has now become a domestic first-class modern machinery manufacturing enterprises. Product marketing at home and abroad.ISO Certificated Jaw Crushers Manufacture From China

Jaw Crusher, Crusher, Crushing Machine

Application of Jaw Crusher:

ZK Jaw Crusher is a trusted and reliable brand for its high quality and good manufacturing. It specializes in producing jaw crusher which is widely applied to crush high hardness, MID hardness and soft rocks and ores such as slag, construction materials, marble, etc. The pressure resistance strength is under 200Mpa, that is, suitable for primary crush. Each model has a large feed opening for its size and an ideal nip angle, giving smooth material flow, high reduction efficiency and high capacity. Their simple design conceals many advanced features that give easy operation, simple maintenance, long life and a low cost per ton.

Jaw Crusher series have many advantages, such as big reduction ratio, even granularity, simple structure, reliable working condition, convenient repair and economic operation, which are widely used for mine, smelting, building material, road, railway, irrigation works, chemical and materials with compression strength no more than 320 Mpa.

The structure of Jaw Crusher:

The structure of Jaw Crusher includes Main Frame, Main Axle, Roller Bearings, Eccentric Shaft, Jaw Plates, Side Plates, Toggle Mechanism, Fly Wheels and Springs.

| model | Size of feed opening | Max feed size | Discharge range opening | Capacity (m3/h) | Motor power (kw) |

| (mm) | (mm) | (mm) | |||

| PE-250x400 | 250x400 | 210 | 20-60 | 3-15 | 15 |

| PE-1000x1200 | 1000x1200 | 850 | 195-280 | 190-275 | 110-132 |

| PE-1200x1500 | 1200x1500 | 1020 | 150-300 | 250-500 | 160 |

| PEX-150x500 | 150x500 | 120 | 10-40 | 3-13 | 11 |

| PEX-300x1300 | 300x1300 | 250 | 15-50 | 20-60 | 75 |

>> Hot sale round hole micro perforated galvanized steel metal sheet by Chinese manufacture

>> Lace Bridal Ball Gown Long Sleeves Luxury Wedding Dresses Z2039

>> Flat Wire High Back Cover USB Products

>> Fishing Accessories 0.40mm 30mx10PCS Connected Nylon Fishing Line

>> Factory Deal Best Price Quick-React Fire-Safe Sprinkler Head Automatic Fire Sprinkler

>> UL/CAS 3 Pin to IEC C13 Power Cord

>> Factory Direct Sales 2400mAh/4800mAh 14.8V Rechargeable Lithium Li-ion 18650 Battery Pack

>> Horizontal CNC Lathe Machine (CK6140 Metal CNC Lathe Machine)

>> 5 Gallon Jerry Can Juice Plastic Bottle Pet Stretch Blow Molding Machine

>> Soft Handle Sample Available and Cheap Price Hand 2024

>> China Standard Production Brand Eworld Wfhj02-4500.3A Three Head Seamless Welding Machine

>> 130HP Self Loading Mobile Concrete Mixer 4m3 From China Factory

>> New Mermaid Princess Castle Crystal Ball Music Box Carousel Music Box Girl Birthday Gift Creative Toys Wholesale

>> Personal 2000mL Tank Capacity double Spray cool mist 4000 battery Night Light portable ultrasonic h2o space air humidifiers

>> Imported Alcohol Drink Fruit Flavour Lager Beer 1L Alcoholic Beverage Manufacture

>> High Precision Drilling Machine Cutting CNC Milling Machine for Aluminum

>> Women′s Thickened Sheepskin Tall Boots

>> Jcb Mini Backhoe Loader 2 Ton for Sale Wheel Backhoe Excavator Loader Backhoe Mini Retroexcavadora

>> Cotton seed remover cotton sheller processing machine

>> Hot Sale Trapezoidal Roofing Ibr Sheet Roll Forming Machine Iron Making Machine

>> Baby Pant Maker Machine - a Powerful Choice for 1000 Ppm Manufacturing

>> Vertical Drilling Machine Upright Drilling Machine 45mm Drilling Capacity Z5045c-1

>> Manufacture Custom Iron on PVC Patch China Wholesale Soft Rubber Patches

>> Wholesale Compartment Food Container Disposable Cpet Trays

>> Modern Comfort boys fishing shirts sublimated DAIWA DE-9321 fishing shirt

>> decorative perforated metal sheets/building material/decorative mesh

>> OEM Eco-Friendly Insect Mosquito Killer Repellent Insecticide Aerosol Spray

>> Taizhoujc Powerful Jc188g 13HP Gasoline Mini Petrol Tiller for Easy Cultivation Tiller

>> Double Zipper Travel Cosmetic Bag Portable Mini Travel Organizer Clutch Bag for Women

>> Morn Hydraulic Vertical Platform Lift for Cargo