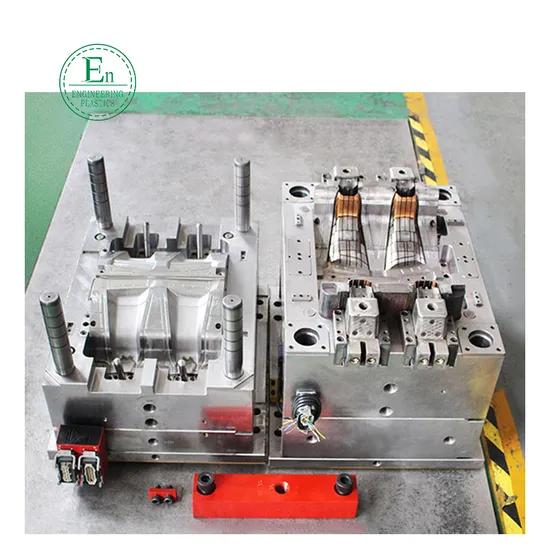

Plastic Die Hot Runner Boxs Custom China Manufacturer Mold Maker Injection Mould

| US$3.00 | 10 Pieces (MOQ) |

Basic Info.

Model NO.

Aut Service Plastic Molding Parts

Surface Finish Process

Polishing

Mould Cavity

Single Cavity

Plastic Material

Plastic

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Hot Runner

Design Software

UG

Installation

Fixed

Certification

ISO

Standard

HASCO

Customized

Customized

After-sales Service

Custom

Color

Custom

Service

OEM\ODM

Drawing Format

2D/(Pdf/CAD)3D(Iges/Step)

Thickness

1-20mm

Transport Package

Boxs

Specification

custom

Trademark

gz-plastic

Origin

China

Production Capacity

5000PCS/Month

Packaging & Delivery

Package Size

40.00cm * 40.00cm * 50.00cm

Package Gross Weight

10.000kg

Product Description

Leading Global Injection Molding Supplier Assist global clients in professional custom injection molding service,CNC machining service and engineering material.We can provide you with one-stop solutions.Main Product: 1.Custom made all kinds plastic injection mold, and custom all kinds plastic injection molding production, and also with surface treatment(paint, print, water trans-print, welding, assemble) . 2.Engineering plastics products Processing: gear and rack,guide,pulley,guide rail,Sealing ring,rod,Tube,and many machined parts ect. Products Tolerance +/-0.01mm.

How to get a quotation: 1. Prepare a picture or 3D drawings; 2. You want the products material;

| Company Name | Guangdong Engineering plastics Industries(Group)Co,Ltd |

| Brand | Guangdong Engineering plastics |

| Main Product | Precision mold, Injection mold, Extrusion mold, Injection plastic products, etc |

| Injection Machine (Double Color) | 88T, 90T, 120T, 168T, 200T,250T,380T,420T,600T,800T,1000T,1200T,1500T,2200T,2800T,3000T |

| Application | Electronics industry, Medical industry, Home appliance industry, Aerospace, Shipbuild industry, Household goods, Automobile industry, Machinery industry,Machinery industry,Semicoductor industry,Food processing, Robot industry,etc |

| Mould Base | LKM Standard,DME Standard,HASCO Standard,FUTABA Standard,Self-made Standad ,etc. |

| Mould Material | 718H/738H/718/738/NAK80/S136/S136H/2738/2316/H13/P20/2344ESR/8407/SKD-61, etc |

| Moud Precision | +/-0.01mm |

| Mould Life | 100K-1000K shots |

| Mould Cavity | Single cavity, multi-cavity |

| Runner System | Hot runner and cold runner |

| Manufacturing Equipments | Guangdong Engineering plastics company has OWM:Imported CNC equipment, EDM machines, Imported mirror wire cutting machines, High-speed precision engraving machines, Laser cutting machines, Sodick slow threading machines, Precision grinders, Plastic injection molding machines,Double color injection machines,etc |

| Plastic Raw Material | Nylon6, Nylon66, PA6, PA66, PA6+GF, ABS, ABS+GF, ABS+PC, POM(Derlin), PP, PE, PC, PVC, PMMA(Acrylic),TRU,EPDM,NBR, Silicon,UHMWPE,PVDF,PTFE,ETFE,PFA,PCTFE,FEP,PVF,PSF, PEI, PSU,PPSU, PPS, PEEK, PAI, PI, PBI,etc. |

| Color | white,black,gray,green,blue,pink,yellow,golden,natural color and custom color,etc |

| Surface Treatment Tech | Polishing,Painting,Electroplate,Anodizing, Brushing, Silk Screening,Water Transfering, Leather Covering,Texture, Sanblasting,Gilding, UV Painting… |

| Product Drawings | 2D Drawings, 3D Drawings, product samples, or the size of the multi-angle pictures |

| Lead time | 15-30 working days for injection moulds,plastic products according to quantity |

| Quanlity System | ISO 9001, RoHS Srandard, etc |

| Our Spirit | "Engineering Plastics" can be used instead of "Steel"! Science and technology will change the future! Guangdong Engineering Plastics Industries Company! |

| Other | 24 hours instant and comfortable customer service! |

| Shipping status notification during delivery! | |

| Regular notification of new styles & hot selling styles! |

The production process of injection mold refers to the process of melting plastic raw materials by heating, then injecting them into the mold, cooling and solidification, and finally obtaining the required molding products. Injection mold production process mainly includes the following steps:

1. Pretreatment of plastic raw materials: including drying, mixing, adding color and other processing to ensure the quality and stability of plastic raw materials.

2. Mold design and manufacturing: according to the shape, size, material and other requirements of the required molding products, design the corresponding mold and manufacture.

3. Injection molding: the pre-treated plastic raw materials are heated and melted, and then injected into the mold, and after cooling and solidification, the required molding product is finally obtained.

4. Finished product treatment: including slag removal, trimming, grinding, painting and other treatments to improve the quality and beauty of the finished product.

Certifications

Companies strictly enforce the ISO9001(2008)international quality certification system, the product quality conforms to the eu RoHS standard.

Application

Our Factory

Our Exhibition

Cooperative Case

>> High Quality Mvh6326 Milling Machine with Keyless Drill Chuck

>> Most Popular Rose Gold Stainless Steel Quartz Couple Watches Pair Watches

>> Auto Engine Spare Parts 97752-2D000 Pressure Sensor for Hyundai KIA Tiburon Elantra

>> 34 Inch 165Hz Ultra Wide Curved Gaming Monitor 3440 X 1440 Va 1800r 1ms (MPRT) Response Time 4K Display Monitor

>> Building Material Laminated Engineered Wood HDF Parquet 8mm Oak Laminate Flooring for Commercial or Residential

>> Customized Versatile Silicone Candle Molds: Striped, Cylindrical and Taper Designs

>> CE Certificated Mini Mining Industrial Equipment Copper Gold Ore Rock Wet Stone Small Horizontal Large Capacity Ball Mill

>> Sliding windows certified by AS2047,AS2208 with double glazed

>> Sddom Small Mobile Portable 25m3/H 35m3/H Concrete Mixing Plant

>> Yeetian Fashion Havana Women Small Butterfly Tortoiseshell Bio Acetate Shades

>> Folding Louver Outdoor Decorative Metal Mesh Brick Facade

>> UL CE cUL Wall Home Decor Make up Smart Vanity Lighted Framed Frameless Round Rectangle Bath Bathroom LED Mirror with Touch Switch Defogger Bluetooth

>> EU Standards Waterproof UPVC Vinyl Casement Glass Door Balcony Door Patio Door

>> Trucking Companies Shipping to Russia Logistics Russia China Goods Bulk Shipping Broker Taxes Cargo Export Agent From Shantou to Moscow

>> Commercial Large Automatic 1.5kw Waffle Basket Production Line Waffle Basket Making Machinery

>> PRO Audio Home Theater Active Amplifier Speaker PA Sound System Powered Speaker

>> Car Grille 7 Series G12 G11 LCI Chrome Front Kidney Grille 5113 7369 904

>> 2022 New 125cc Kids ATV Adult Quad Bike 4 Wheel Petrol

>> PU Football (JYB-HW001)

>> China/Japan Engine Heavy Duty 10ton Forklift Machine Price Fd100

>> 20oz 13.5" Hollow Fiberglass Handle Claw Hammer Hand-Tools Hammer

>> 7-Inch S-Type Fpv Drone Mark4 7-Inch S-Type

>> Customized Industrial Sewing Line Center Table with Light for Garment Factory

>> Women′s Cold Weather Windproof Thick Warm Hiking Gloves

>> Pig Chicken Manure Dewater Solid Liquid Separator Drying Machine

>> Horizontal Pulse Vacuum Steam Sterilizer Autoclave

>> C6136D Precision Turning Machine Manual Universal Metal Bench Lathe

>> Mini Block Making Machine Asphalt Paver Cement Block Making Machinery Tka Product Genre

>> 24AWG 4 Paris FTP Cat5e Cable LAN Cable Network Cable

>> Advanced Electric Van Truck with Refrigeration for Cold Transport-Hpx20