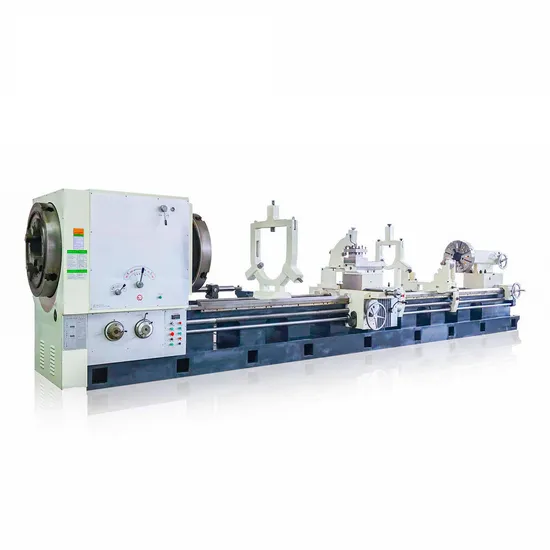

High Precision Quality Heavy Duty Oil Country Tube Lathe Machine Q1313 China Big Large Spindle Bore Manual Horizontal Metal Pipe Threading Lathe Price

| US$14,800.00-17,900.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

Q1313

Type

Horizontal Lathe

Processing Accessory

Chuck CNC Lathe

Guide Rail

Horizontal Guide Rail

Tool Holder

Single-tool Holder CNC Lathe

Power Source

Mechanical Drive

Controlling Mode

Artificial

Automatic Grade

Semiautomatic

Setting Mode

Floor-type

Precision

High Precision

Certification

GS, CE, RoHS, ISO 9001

Condition

New

Swing Over Bed

630/800mm

Swing Over Cross Slide

340/520mm

Distance Between Centers

1500/3000mm

Pipe Threading Range

30-126mm

Guideway Width

550mm

Max. Load Capacity

3000kg

Spindle Bore

130mm

Spindle Speed Steps

30-650rpm 9/18 Steps

Chuck

φ400 3-Jaw Manual

Turret/Tool Post

Manual 4 Position

Tool Shank Size

30 X 30mm

Tailstock Quill Diameter

100mm

Tailstock Quill Taper

Mt5

Tailstock Quill Travel

250mm

Main Spindle Motor

11kw

Transport Package

Plywood Case

Specification

5200x1500x1500mm

Trademark

shenghuan

Origin

China

HS Code

8458190000

Production Capacity

2000

Packaging & Delivery

Package Size

520.00cm * 150.00cm * 150.00cm

Package Gross Weight

5200.000kg

Product Description

Product DescriptionLathe Machine Q1313 China Manual Horizontal Pipe Thread Lathe Price

Product Parameters

Application:

Q13 series pipe threading lathe machine is mainly used for turning the internal and external threads including metric and inch thread,as well as having all the common functions of normal engine lathe such as processing the inner bore and end face of shafts and disks,this machinery is equipped with taper guide bar device which enables this series to process taper thread.

This series lathe machine is widely used in industries including petroleum exploiting ,coal and minerals mining,chemical piping and geological prospecting,it is high-efficiency equipment in processing and repairing drilling pipe,drilling rod,thread coupling and so on.

The main performance characteristics:

Big spindle bore and double chuck allows clamp and process big diameter pipes;

Integral machine bed adopts high strength iron to relize high rigidity and precision;

Ultrasonic frequency quenched guide-ways are hard enough for good wear-resistance;

Equiped with taper guide bar device this enables the machine to process taper threads.

Standard accessories:

Tool post,Tailstock,Chuck,taper guide bar,Lighting lamp,Coolant pump,Rear support bracket,Pad iron etc.

Optional accessories:

Digital readout,Chuck,Faceplate,Chasing dial,Center rest,Signal light,Protective cover(lead-screw,chuck,tool post),and Grinding attachment etc.

| Main technical specifications | SPECIFICATIONS | Units | Q1313 | Q1319 | Q1322 | Q1325 | Q1327 | Q1332 | Q1338 | Q1343 | Q1350 |

| Swing over bed | mm | 630/800 | 630/800 | 630/800 | 800 | 1000 | 1000 | 1000 | 1000 | 1200 | |

| Swing over cross slide | mm | 340/520 | 340/520 | 340/520 | 480 | 610 | 610 | 610 | 610 | 710 | |

| Distance between centers | mm | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | 1500/3000 | |

| Pipe threading range | mm | 30-126 | 50-193 | 50-220 | 120-250 | 130-270 | 190-320 | 190-380 | 270-430 | 330-510 | |

| Guideway width | mm | 550 | 550 | 550 | 600 | 755 | 755 | 755 | 755 | 755 | |

| Max. load capacity | kg | 3000 | 3000 | 3000 | 4000 | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Spindle bore | mm | 130 | 200 | 230 | 255 | 280 | 330 | 390 | 440 | 520 | |

| Spindle speed steps | - | FWD.18 steps/ | VF. 4 steps | VF. 4 steps | VF. 4 steps | FWD. 12 steps | FWD. 9 steps | FWD. 9 steps | FWD. 9 steps | FWD. 9 steps | |

| REV.9steps | |||||||||||

| Spindle speed range | rpm | 30-650 | 20-550 | 20-550 | 20-420 | 16-380 | 7.5-280 | 6-205 | 4.9-180 | 4.9-180 | |

| Chuck | mm | φ400 3-jaw manual | φ520 4-jaw manual | φ520 4-jaw manual | φ630 4-jaw manual | φ800 4-jaw manual | φ780 4-jaw electric | φ850 4-jaw electric | φ1000 4-jaw electric | φ1000 4-jaw electric | |

| Turret/tool post | - | /Manual 4 position | Manual 4 position | Manual 4 position | /Manual 4 position | Manual 4 position | Manual 4 position | Manual 4 position | Manual 4 position | Manual 4 position | |

| Tool shank size | mm | 30 x 30 | 32 x 32 | 32 x 32 | 32 x 32 | 45 x 45 | 45 x 45 | 45 x 45 | 45 x 45 | 45 x 45 | |

| X axis travel | mm | 320/420 | 320/420 | 320/420 | 420 | 520 | 520 | 520 | 520 | 520 | |

| Z axis travel | mm | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | 1350/2850 | |

| X axis feed steps/range | mm/r | 22/0.02-0.45 | 22/0.02-0.45 | 22/0.02-0.45 | 22/0.02-0.45 | 40/0.05-1.5 | 32/0.05-0.75 | 32/0.05-0.75 | 32/0.05-0.75 | 32/0.05-0.75 | |

| Z axis feed steps/range | mm/r | 26/0.07-1.33 | 26/0.07-1.33 | 26/0.07-1.33 | 26/0.07-1.33 | 40/0.1-3.0 | 32/0.1-1.5 | 32/0.1-1.5 | 32/0.1-1.5 | 32/0.1-1.5 | |

| X axis rapid traverse | mm/min | 2300 | 2300 | 2300 | 2300 | 1870 | 1870 | 1870 | 1870 | 1870 | |

| Z axis rapid traverse | mm/min | 4000 | 4000 | 4000 | 4000 | 3740 | 3740 | 3740 | 3740 | 3740 | |

| Metric thread kinds /range | mm | 1952/1/24 | 1-15 | 1-15 | 1-15 | 30/1-30 | 23/1-15 | 23/1-15 | 23/1-15 | 23/1-15 | |

| Inch thread kinds /range | T.P.I | 40/28-2 | 14-1 | 14-1 | 14-1 | 27/28-1 | 22/28-2 | 22/28-2 | 22/28-2 | 22/28-2 | |

| Tailstock quill diameter | mm | 100 | 100 | 100 | 120 | φ160 | φ160 | φ160 | φ160 | φ160 | |

| Tailstock quill taper | - | MT5 | MT5 | MT5 | MT6 | MT6 | MT6 | MT6 | MT6 | MT6 | |

| Tailstock quill travel | mm | 250 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 300 | |

| Main spindle motor | kw | 11 | 11 | 11 | 15 | 22 | 22 | 22 | 22 | 22 | |

| Rapid traverse motor | kw | 0.3 | 0.3 | 0.3 | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Coolant pump motor | kw | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | 0.125 | |

| Weight for 1500 | kg | 40000 | 4300 | 4500 | 8000 | 10000 | 11500 | 12800 | 13000 | 15000 | |

| Weight for 3000 | kg | 52000 | 5500 | 5700 | 9000 | 11500 | 13000 | 14300 | 14500 | 16500 | |

| Dimension for 1500 | mm | 3700x1500 | 3700x1550 | 3700x1650 | 4100x1700 | 4800x2100 | 4900x2100 | 4900x2100x1700 | 5000x2100x1700 | 5000x2100x1850 | |

| x1500 | x1550 | x1550 | x1600 | x1600 | x1650 | ||||||

| Dimension for 3000 | mm | 5200x1500 | 5200x1550 | 5200x1650 | 5600x1700 | 6300x2100 | 6400x2100 | 6400x2100x1700 | 6500x2100x1700 | 6500x2100x1850 | |

| x1500 | x1550 | x1550 | x1600 | x1600 | x1650 |

Realistic photos

Detailed Photos

Our Advantages

Certifications

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on .

3: Where is our factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;

Irrevocable LC at sight .

5: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

We want to know:

1.What's your Industrial Voltage?

2.We strongly suggest you to tell us size, material of your workpiece for our evaluation, if possible, better to send us workpiece drawing, so that we can recommend you most suitable model!

3.If need CIF Price, please kindly tell us the port of destination.

>> Food Factory Cold Warehouse PVC Fabric Retractable Loading Bay Loading Container Logistics Anti-Crush Adjustable Inflatable Dock Shelter Dock Door Shelter

>> MD1420h/Fx800 MD1432bx1000 Large Diameter Cylindrical Grinding Machine

>> Sintered Metal Part for Portable Winches

>> Customized Tungsten Carbide Punch for Progressive Die

>> Taijia Dalian Tmeasurement TUF2000H Portable Hand Hold Flow Measuring Instruments Water Ultrasonic flow meter

>> 20 Heads High Speed Embroidery Machine

>> Engine Coolant Water Pipe for Audi Car Parts

>> High-Performance Drilling Tools for Plywood and Wood Projects

>> Cationic Amino Silicone Emulsion for Imparts Excellent Softness and Hydrophobicity Siem-2930c

>> ASTM B381 Grade 12 Alloyed Titanium Forging Pipe for Industry Use

>> Yc Precision High Level Stainless Steel Ring Gasket

>> Hot Sale Jaw Plate Bearing Check Plate for Jaw Crusher

>> multifunction beans mill/wheat grinder/rice mill machine

>> Expert Supplier of Rubber Roller Calender Roller Mirror Roll

>> Double Shaft Waste Tyre Shredder Tire Recycling Shredder Tire Recycling Machine Manufacturers

>> Aeon 63" X 39" 60 Watt CO2 Laser Tube for Engraving with Ruida Control Lightburn Software Compatible with Windows, Mac Osx, Linux 80W 100W 130W 150W RF30W/60W

>> 82006010 New Holland Truck Clutch Disc

>> Foreign Trade Leak out of The United States High-End Cowhide Us Money Bag Male Ultra-Thin Short Anti-Theft Brush Cross-Border Business Card Bag

>> Fresh Semi Dried Ginger Roots Air Dired Ginger Organic Ginger Customized Package

>> Computerized Hat Embroidery 4 Heads 12 Needles Machine-Gantry Structure

>> Commercial Food Cutting Machine Pastry Molding Machine Multi-Function

>> Russia Standard GOST 8732-78 Hot Rolled Deformed Welded Round Tube HDG Galvanized Seamless Carbon Steel Pipe

>> used double glass swing entry wrought iron door for outdoors

>> Factory Price 22cm Height Portable Folding Stool Kids Foldable Stool

>> Corduroy Embroidered Shirt Fashion New Men′s Shirt

>> 12V Jump Start Multifunction Jump Starter Power Bank with Flashlight Portable Car Battery Jump Starter

>> GS8 Max Smart Watch

>> as-C2806-1high Back Computer Leather Cheap Gamers Gaming Chair

>> Alcohol Soluble Polyamide Resin PA Resin Similar to Unirez 2215

>> Low Investment Cooling Equipment for Effective Feed Pellet Cooling