Corrugated Box Making Machine 2 Ply Corrugated Machine Single Facer Line

| US$30,000.00-32,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

SF280-1400

Condition

New

Certification

CE

Automation

Automatic

Suitable for

Paper

Paper Thickness

Normal Specification Paper

Product Name

Corrugated Paperboard Production Line

Machine Type

Fingerless Vacuum

Model

Sf295-1600

Width

1600

Flute Roller Dia.

295

Pre-Heater Roller

320

Gluing Roller

215

Design Speed

100m/Min

Working Speed

0-80m/Min

Heating Way

Steam/Electric

Transport Package

Container

Specification

1600

Trademark

Xinglong

Origin

China, Hebei

HS Code

8441309000

Production Capacity

100 Sets Per Year

Product Description

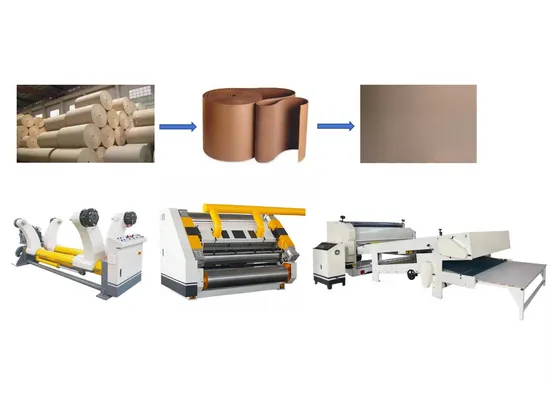

corrugated box making machine 2 ply corrugated machine single facer line facer2 Ply Corrugated Paperboard Production Line Single facer group = electric roll stand+single facer+sheet cutter with stacker Detailed information SF280-1600 single facer machine

INSTRUCTON AND FEATURES

1. Paper feeding way is vacuum suction way and perfect flute formation in high speed production.

2. Available width:1400/1600/1800/2000/2200 mm

3. Flute type: A, B, C, D, E, F,G UV

4. Corrugated roller:φ280/300/320/360/380mm

5. Drive using chain drive

6. The glue coating part adopt automatic circulating glue feeding way (manual or electrical isolation device)

7. Pneumatic control to adjust the glue feeding and adjust gluing capacity electrically or manually; the glue parts running separately while the main motor stopped, prevent paste from drying up.

8. It is equipped with the high pressure powerful air fan with the wind capacity adjustable device and silencer; air source and electric control are in one cabinet

9. The machine wall made by cast iron and thickness 130mm

10. The corrugated roller materials 50CrMo alloy, the inner hole is fine bored, tempered and finish turned and the surface is medium-frequency quenched, CNC polished and fine grinded and hard chrome-plated.

11. The corrugated roller diameter ¢280mm; Hardness can reach more than HRC60 which ensures good wear-resistance and long life service.

TECHNOLOGY PARAMETERS

| Model | SF280-1600 |

| Working width | 1600 mm |

| Heating way | electric |

| Flute type | A B C D E F |

| Operate direction | Left or right according to customer's factory |

| Designed speed | 60m/min |

| Economic running speed | 30-40m/min |

| Temperature range | 160-200ºC |

| Air source | 0.4-0.8Mpa |

shaftless mill roll stand

INSTRUCTON AND FEATURES Hydraulic drive,smooth when running,fast change paper roll,easy adjustment Symmetrical structure can install two rolls of paper at the same time and continually change paper roll; It adopts motorized control clamping, loosen, up-down, movement, contraposition, translation . Equipment was made of HT200-wide casting It adopts pneumatic braking. Electrical components are controlled centralized(domestic brand) TECHNOLOGY PARAMETERS

| Max working width | 1600 |

| Min working width | 600mm |

| Max paper roll diameter | 1500mm |

| Single Side carriage | 2000kg |

| Air pressure | 0.6-0.9Mpa |

| Power | 4.5kw |

1. Single knife sheet cutter can do set-length cutting reel paper and single facer board, change order fast, high cutting precision, fast work speed, low waste, it also suit for color-printing box package.

2. Adopts adjustable-speed motor reduce the fault caused by transmission wearing.

3.teeth surface be quenching and grinding, high precision transmission, low noise, transmission part lubrication adopts oil pump automatic recycle design.

4. Used high speed flat type knife, high hardness with long use life. Precision adjustable gapless gear ensure accurate mesh, good cutting with high straightness, protect knife

TECHNOLOGY PARAMETERS

| Design speed | 80m/min |

| Working speed | 0-60m |

| Cutting length | 300-9999mm |

| Cutting precision | ±1.5mm |

| Effect width | 1600mm |

| Cutting layer | single layer,double layer |

Certifications

Packaging & Shipping

>> Ginger Powder Hammer Mill Crusher Grinder Grinding Machine Powder Making Equipment

>> Cheap Luqi Electric Scooter 1000W Motorbike Golf Scooter 25ah Citycoco Electric Scooters

>> Precast Concrete House Home Machine Manufacturing Lightweight Sandwich Hollow Core EPS Wall Panel Production Line Plant for Building Material Making Machinery

>> Funjump 4X6FT Toddler Rectangular Trampoline with Safety Net Enclosure

>> Automobile Interior Fittings Plastic Motion Control Components Rotary Damper Injection Molding Service

>> Multi-function Vertical and Horizontal Drilling Milling Machine X6332Z

>> plastic tube 3973197 3973246 3973387 3973388 3973393 3973458 3973961 3974089 3974114 3974115 3974117 3974118 for cummins engine

>> SVC-500va Automatic Voltage Stabilizer, SVC-500va AC Automatic Voltage Regulator

>> Clinic Furniture Electric 5 Functions ICU Ccu Medical Patient Nursing Hospital Bed

>> BBQ Grill Net Barbecue Mesh Mat

>> DC Inverter Compressor R410a 110V 18000BTU Solar Powered Ac/DC Hybrid Solar Surface Pump 3 Hp

>> 52cc Petrol Drilling Machine (TT-GD520-2)

>> Aluminum glazed sliding window

>> Loudspeaker PRO Audio Voice Coils

>> Christmas Decoration DIY Wooden Elk Christmas Tree Xmas Table Ornament Navidad 2023 New Year Kids Gifts Merry Christmas 2022

>> Cheap Embroidery Machine Single Head 12 Needle Dahao Computer 300*400mm

>> Easy to Operate 1/8 "1/4" -2 "4" "Hydraulic Hose Crimping Machine Hose Pressing Machine

>> Desktop 2D 3D Automatic Tool Changer Woodworking 600*900mm CNC Router Machine Carve Wood

>> Used Pellet Granules Machine for Used Plastic Waste Plastic PP Pepelletizing Line

>> Cnbf Flying Auto Part Suitable for Honda Civic Shock Absorber

>> Plastic Blow Moulding Machine 120L 150L 200L 220L 250L Plastic Drums Extrusion Blow Molding machinery Gallon Barrel Blow Molding Making Machine

>> 90GSM 3D Printed 100% Microfiber Deep Pocket Bed in a Bag 4PCS Bed Fitted Sheet Set for Boys

>> Chemical Lace Water-Solubility Web Fabric Embroidery Lace

>> Wooden Musical Toys Musical Instrument of Wood Fish Type Tone

>> Tsd63-315 Type Pipe Butt Fusion Welder for Pipes Welding

>> Taiwan King Steel Brand Jugang Factory Horizontal Boring and Milling Machine, Jg6513

>> Effective Face Beauty 7 Colors LED Facial Mask LED Light Therapy Device

>> Steel Tile Construction Vehicle Aerial Work Hydraulic Lifting Platform Equipment

>> Electrical Pvc Trailer Cable Weather Proof Swimming Pool Accessories Plastic Junction Box

>> Commercial 2000L Brewery Equipment Fully Integrated Brewing System for Craft Beer Production, Steam or Electric Heating