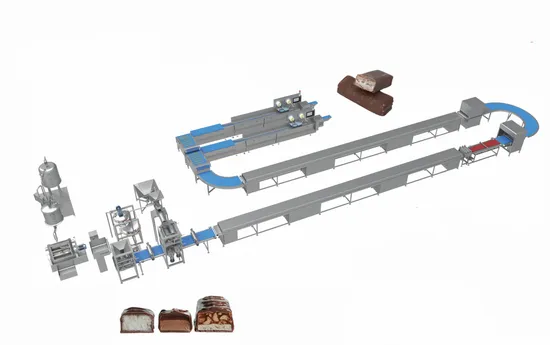

Snickers Nougat Bar Making Machine Chocolate Bar Production Line

| US$1,000.00-500,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

BG-800

Certification

CE, ISO9001

Power Source

Electric

Process

Thermal Processing

Automatic Grade

Automatic

Application

Candy, Chocolate, Snicker Bar, Nougat, Caramel Bar, Protein Bar

Customized

Customized

Type

Forming Cooling Cutting Machine

Raw Material

Stainless Steel

Lead Time

90 Days

Cooling Tunnel Length

Selective

Roller Width

340mm 540mm (Customized)

Output

500kgh 800kgh (Customized)

Packaging

Wooden Case

Driven Type

Servo Motor

Line Length

According to Customer&Prime′s Workshop

Enrober

Selective

Transport Package

Cartons

Specification

300kg

Trademark

HULK

Origin

China

HS Code

8422303090

Packaging & Delivery

Package Size

5600.00cm * 2300.00cm * 2300.00cm

Package Gross Weight

9000.000kg

Product Description

Product DescriptionAutomatic Production line for snicker bar, nougat, caramel bar )

Product Parameters

Forming Rollers units(for nougat and caramel)

Function: form the mass to flat layer through forming rollers units.

Nougat and cereal only need two forming rollers and related pressed rollers. Toffee will need 4 forming rollers and related pressed rollers. Toffee need four rollers to make the mass more thin and flat.

Nougat Forming Rollers Units

| Product description | Forming rollers units for nougat |

| Roller Diameters*Width | Upper Roller:φ500*Width:540mm Nether roller:φ700*Width:540mm |

| Output mass width | 540mm |

| Product thickness adjusting scope for single layer | 5mm-40mm |

| Roller Materials | Iron with teflon coating |

| Roller stainless steel thickness | 15mm |

| Jacket layer thickness | 30mm |

| Roller Coating | Teflon coating by Dupont |

| Roller speed | 3-6M/Min |

| Motor power | 370W |

| Motor brand | ABB |

| Frequency converter | Siemens |

| Cooling medium | Ice water, glycol, etc. |

| Complete dimension | 800*1300*1500mm |

| Complete Weight | 300kg |

Cooling Tunnel

| Width of conveyor belt | 600mm |

| Effective Length | 18000mm |

| Machine Structure(contact part) | 304 stainless steel |

| Cooling Type | Water or Wind Cooling |

| Belt Speed | 2-3.5M/Minutes |

| Main Feature | Cooling tunnel has the temperature sensor, temperature can be controlled by temperature controller. |

| There are pneumatic rectifying belt devices in front and back rack. feeding part is with check rails avoiding products falling down | |

| Main Electrical Parts | Schneider |

| Motor | ABB |

| Belt Materials | Germany Siegling |

Slitting Units

| Model | BG-S800 |

| Machine Materials(contact part) | 304 SS |

| Total Power | 2KW |

| Mass max width before spreading | 540mm |

| Slitting Width | According to requirement |

| Knife materials | 304 SS |

| Machine Dimension | 3400*1200*1600mm |

| Motor brand | ABB |

| Motor Quantity | 3pcs |

| Frequency Converter | 3pcs |

| Other Electrical parts | Schneider |

Transversal Cutter

| Model | BG-T800 |

| Single Knife width | 690mm |

| Cutting width | 690mm |

| Machine materials(contact part) | SS 304 |

| Longitudinal Knives coating | Teflon coating by Dupont |

| Cutting Length | 20-200mm |

| Cutting speed | MAX 100times/min |

| Servo Motor Brand | Panasonic |

| General motor | Siemens or ABB |

| Electrical parts | Schneider |

| Belt Materials | PU |

| Power | Two servo motors: one is 1kw,another is 5kw |

| Transversal cutting machine | 2000*1200*2000mm |

FAQ

Machine installation we have the chinese technician to visit abroad for machine installation.

During the pandemic, we will take a complete installation video before machine delivery.

All the machine running will be tested and machine operation will be taken in the video. when client receives the machine, we will provide the online support to u. Why Choose Us

Our boss is the engineer, Once there is good structure, we will upgrades the technology constantly. We have the 30000m2 production area, professional technical team. We provide the rapid technology support, after-sales service. U can trust us.

Company Profile

Taizhou Hulk Food Machinery is the originated food confectionary machine manufacturer, concentrating on confectionery and chocolate bar packing machine, slab bar line, bar moulding machine, bar extruder and confectionery kitchen, . Basing on the principal of technology changing life, Taizhou Hulk Food Machinery constantly upgrade the technology and enhance the quality to meet more strict quality requirement. The technology research team is the guide and assurance for the company development.Hulk Food machinery insist on creating win-win situation for client, bring convenience and save the cost.

>> Continuous Use Pyroylsis Equipment with Free Installation

>> Interactive LED Touch Screen Monitor 75 Inch

>> Tiffany Stained Glass Rose Lamp for European Wedding Decoration

>> OEM Customized Wiring Assembed Stainless Steel Aluminum Metal Distribution Box

>> Pet Supply Stainless Steel Dog Nail Clipper Dog Clipper Cat Grooming Tool Pet Nail Clipper

>> Active Full-Range Speaker Powered Speakers PA System Concert Sound System Loudspeaker

>> Factory Supply Freeze Dried Durian Extract Powder Durian Fruit Powder

>> Rubber High Quality Fitness Soft Natural Rubber Yoga Mat for Layer Exercise

>> Super Soft Coral Fleece with Waffle Style Microfiber Hair Towel Turban

>> 25m3 35m3 Trailer Type Concrete Batching Plant

>> CE Certification Lump Breaker Hopper Hanningfield Lump Breaker

>> Mobile Phone LCD for Samsung A02s A025 A03 A035 A03s A037 A04e A042 Universal Display Touch Panel Screen Digitizer Assembly

>> Commercial Escalator with Cheap Price

>> First Aid Bandage with Non-Woven Fabric and Cotton Pad

>> Sunze Cuticle Aligned European Russian Unprocessed Virgin Raw Hair Ha Lo Hair Extension

>> Factory Customized 8K HD Video Cable, HDMI 2.0 and HDMI 2.1 Cables

>> Excellent Performance Manufacturer Solar Thermal Collector

>> Bulldozer D6h Front Idler Undercarriage Idler Ass′y for Cate Rpillar Parts

>> Small Granite Stone Rock Ore Mining Pyb Spring Cone Crusher Price for Sale

>> High Quality Timing Chain Kit TK1539 for VW for AUDI for SKODA EA111/BAG with OE No.03C109158B;03C109507L

>> 14W 20W 30W LED Wall Ceiling Microwave Sensor Ceiling Light with Modern Design

>> Spectrophotometric Total Phosphorus Monitoring System with Online Capability

>> Metal Bar Peeling Lathe Machine Made in China

>> Blade Sharpening Flat Machine for Straight Crusher Knife

>> 4~60mm Manual focus iris for vari-focal mechanical vision lens SLR camera lens follow spotlight

>> White Ink Digital A3 Dtf Printer T Shirt All Fabric

>> Heat Insulation Corrugated Roof Sheet

>> Edunburgh Nice Looking Type Villa Type Passenger Elevator Lift for Public Projects

>> Press to Open Circular Plastic Desktop Trash Can with Patterns and Sleeves Dustbin

>> Adjustable Galvanized Cow Stall Divider