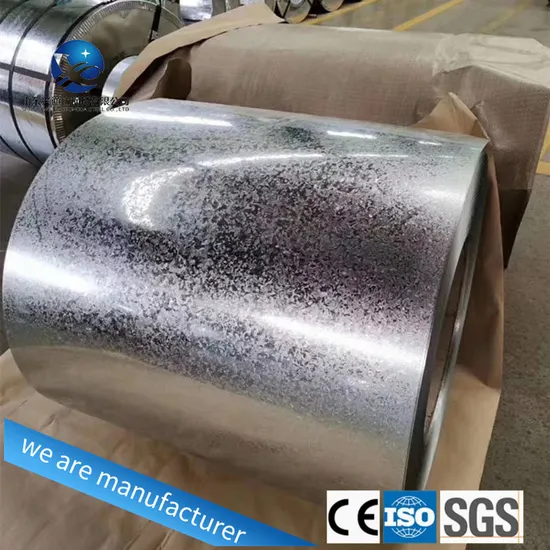

Dx51d Z350 Zinc Coil High-Precision Dx51d Z60 Cold Rolled H180bd+Z H220bd+Z Hot Rolled Durable Using Z275 Galvanized Steel Coil

Basic Info.

Model NO.

DX51d/DX52d/Dx53d/SGCC

Standard

ASTM, JIS, GB, AISI, DIN, BS

Certification

ISO, RoHS, IBR

Surface Treatment

Galvanized

Technique

Cold Rolled

Application

Boiler Plate

Edge

Slit edge

Stock

Stock

Spangle

Big/Zero/Normal

Width

600-1250mm

Hardness

Hard, Soft, Full Hard--Hrb<=95

Zinc-Coating

30-275G/M2

Surface

Chromed, Dry, Unoil

Package

Plastic Bag+Waterproof Paper+Steel Sheet Strip

Coil Weight

3-8tons

Coil ID

508mm and 610mm

MOQ

1ton

Delivery Time

7-10 Working Days

Transport Package

Standard Sea Transport Packaging

Specification

Customizable

Trademark

Xingtongda

Origin

China

HS Code

7210490000

Production Capacity

200000tons/Year

Product Description

Shandong Xingtongda Steel Co., Ltd was founded in 2020 with a registered capital of 10 million RMB and has more than 20 years of experience in the steel industry. Our annual sales nearly one billion, about 300, 000 tons steel.Our company is located in Liaocheng City, Shandong Province. We entered into a strategic partnership with Rizhao Steel, Jinan Steel, Laiwu Steel, Handan Iron and Steel, Anyang Iron and Steel, Maanshan Iron and Steel and other domestic large steel companies. Shandong Xingtongda Steel is the largest steel agent in Shandong Province, we also have ourselves steel manufacturing factory, and our stock always no less than 10, 000 tons.We always focused on the integration of resources, in line with the concept of win-win cooperation. With efforts of our staff we have the pleasure to serve the clients from more than 20 countries and areas, We earned good reputations from the clients without any claim. We finally become good friends and intimate partners with them.Xingtongda steel regards moral integrity as fundamental, relying on advantages of resources, we will ensure the most reliable quality and very good prices.

For galvanized coils, the sheet steel is immersed in a molten zinc bath to make a sheet of zinc coated on its surface. It is mainly produced by continuous galvanizing process, that is, the rolled steel plate is continuously immersed in a plating tank with zinc melted to make galvanized steel plate; alloyed galvanized steel plate. This kind of steel plate is also manufactured by hot dip method, but immediately after being out of the tank, it is heated to about 500 ºC to form an alloy coating of zinc and iron. This galvanized coil has good paint adhesion and weldability.Product Parameters

| Product Name | Hot Dipped Galvanized & Galvalume Steel Coil,Zinc Coated Steel ,GIHDGI,aluzinc Steel |

| Standard | EN10346, JIS G3302, ASTM A653,AS 1397,GB/T 2518,ASTM A792 |

| Steel Grade | Dx51D, Dx52D, Dx53D, DX54D,DX55D,DX56D,DX57D, S220GD, S250GD, S280GD, S320GD,S350GD, S390GD,S420GD,S450GD,,S550GD, SGHC, SGH340, SGH400, SGH440, SGH490,SGH540, SGCC,SGCH,SGCD1, SGCD2, SGCD3, SGCD4,SGC340, SGC400 , SGC440, SGC490,SGC570; CS-A,CS-B,CS-C,Grade 33,grade 37.grade 40,garde 50,grade60,grade70,grade80 G1,G2,G3,G250,G300,G450,G550 As Requirement |

| Type | Coil/Sheet/Plate/Strip |

| Thickness | 0.12mm-6.0mm or 0.8mm/1.0mm/1.2mm/1.5mm/2.0mm |

| Width | 600mm-1800mm or 914mm/1000mm/1200mm/1219mm/1220mm/1524mm |

| Zinc Coating | Z30g/m2-Z600g/m2&AZ20-AZ220 |

| Surface Structure | Normal spangle (N),, spangle-free(FS),Zero Spangel |

| Surface Structure | Oiled (O),Passivated(C),Passivated and oiled (CO) ,Sealed (S),Phosphate (P),Phoaphte and oiled (CO)/AFP |

| Coil Weight | 3 Tons -8Tons |

| Coil ID | 508mm/610mm |

HIGH QUALITY MATERIAL SELECTIONSelect excellent steel, precise chemical composition, uniform material, not easy to corrosion. SMOOTH SURFACE WITHOUT BURRS

The technology is mature and the production is strictly in accordance with the process specifications. The cutting surface is smooth and clean without burrs, and the galvanizing is even and smooth.CUSTOM PROCESSING

Can be customized for production and cutting according to customer requirements.Packaging & Shipping

Certifications

FAQ

1.Q:How to choose hot-dip galvanized coil and electroplated galvanized coil?

A:Hot dip galvanized coils are suitable for highly corrosive environments and outdoor applications, while electroplated galvanized coils are suitable for applications that require high surface smoothness but low corrosiveness, such as household appliances and automotive components.

2.Q:What is the corrosion resistance of galvanized coils?

A:Galvanized coils have excellent corrosion resistance, and the zinc layer can effectively isolate the steel from contact with the external environment, extending the service life of the steel, especially in humid environments.

3.Q:What processing techniques are suitable for galvanized coils?

A:Galvanized coils are suitable for various processing techniques, such as cold bending, stamping, welding, and shearing, and are particularly suitable for forming and component manufacturing.

4.Q:How to carry out anti-corrosion treatment on galvanized coils?

A:Galvanized coils have already undergone galvanizing treatment during the production process. If further anti-corrosion is required, spraying, plastic spraying, or adding anti rust paint can be used to improve their corrosion resistance in special environments.

5.Q:What is the environmental performance of galvanized coils?

A:Galvanized coils have good environmental performance, and the zinc layer can extend the service life of steel and reduce the frequency of replacement. Meanwhile, discarded galvanized coils can also be recycled and reused to reduce resource waste.

6.Q:What is the fire resistance of galvanized coils?

A:Galvanized coils themselves do not have fire resistance, but the zinc layer can provide some protection in a short period of time. In situations where fire prevention is required, additional fire-resistant coating treatment is usually necessary.

>> Micro-Cultivator for Farmers: Compact Walking Tractor for All Fields

>> New Style Wear Resistant Stretch Flexible Safety Outdoor Protection Golf Glove

>> Top Quality body kit for BMW X6M body kits for BMW X6 E71 body kit HMY EVO M TYCOON STYLE 2008-2013 Year

>> China laminated pp woven urea pp zipper rice feed fertilizer manure plastic price 50kg bag

>> Multiple Cavity Bottle Caps Mould Making Plastic Caps for Plastics Bottles Cap Mould for Injection Mold Machine

>> Genuine Auto Parts Rear Lips For Benz C Class W204 C300 PP Primer Rear Diffuser With Silver Exhaust Pipe

>> Good Quality Crusher Spare Parts Suitable for Jaw Crusher and Cone Crusher/OEM mm0514925

>> Full-Automatic Waste Plastic PP/PE Film /Pet Bottle Flakes Recycling Washing Machine

>> Plastic Large Basin Set Bath Plastic Making Injection Molding Machine

>> Lab Manual Roller Press Calender Machine Electrode Calendering Machine for 18650 Lihtium Battery Electrode Making

>> Gun Metal Drilling Machine 3-Axis CNC Deep Hole Drilling Machine for Mould Industry

>> Metric Measuring Wheel (900011)

>> 4*8FT CNC Router Woodworking Machine 1325 Atc CNC Wood Router for MDF Cutting Wooden Furniture Door Making

>> China Resonabale Price CNC Cylindrical Grinder Centerless Grinding Machine for Cylinder Needles

>> Rapier Weaving Machinery Loom Electronic Ldec Platform for Air Jet Loom

>> Direct Black 22 Black GF 150% CAS: 6473-13-8 Textile Dye Direct Dyestuff

>> 3D Design Custom Gafas De Sol Man Trending Acetate Polarized Trendy Women Lunette De Soleil Sunglasses

>> 25 Shore White Liquid RTV2 Silicone Rubber for Resin Crafts Molds

>> ASTM Sch40 Plastic (UPVC) Pipe Fittings in ASTM-D-2466 Standad for Supply Water (ELBOW, TEE, SOCKET, REDUCING BUSH, etc.)

>> Permanently Salon Beauty Equipment Non Channel 808nm Diode Laser For Hair Removal

>> Australian Standard aluminium bi fold window fold up glass windows

>> Innovative Rice Freshness Assessment Tool for Optimal Quality

>> Indoor Bowling Machine Entertainment Center Standard Lane Bowling Complete String Pinsetter Equipment

>> Great Black Kitchen Faucet Factory High-Quality Faucets Kitchen GLS229s49A Brushed Single Lever Kitchen Faucet Hot Sale Modern Stainless Steel Kitchen Faucet

>> Single Head 15 Needles China Flat Cap T-Shirt Hat Computerized Embroidery Machine

>> Slant Bed CNC Lathe Machine Center TCK500GP CNC Turning Center Machine

>> High Resolution Floor Standing LCD Screen Battery Powered Portable Digital Signage

>> Hoosun Smart Bead Mill - Disc Type for Micro and Nano Materials: Printing Inks, Coatings, Pigments, Graphite, Batteries

>> Baoli Pull-Back Cartoon Airplane Set, 4-Pack Mini Plane Vehicles for Toddlers, Early Learning Toy for Boys and Girls

>> Brc Ad Dehydrated Slice Red Yellow White Powder Onion Granules