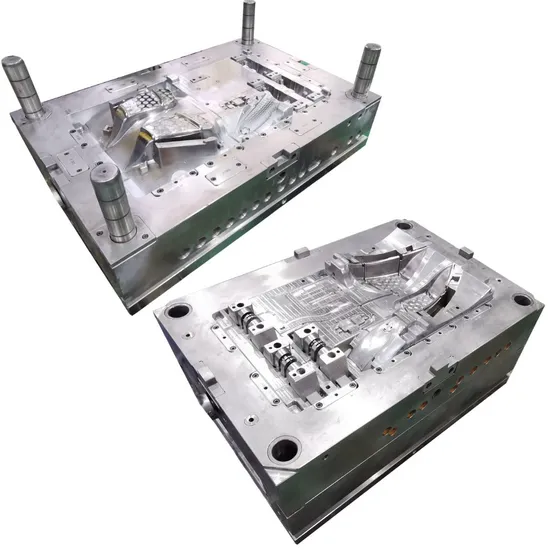

Household Plastic Component Manufacturing Low Price High Quality Custom Molded Product

| US$2,600.00-6,000.00 | 1 Set (MOQ) |

Basic Info.

Model NO.

Plastic Injection Mould-1

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Plastic Material

ABS

Process Combination Type

Single-Process Mode

Application

Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

Runner

Cold Runner

Design Software

UG

Installation

Fixed

Certification

ISO

Standard

DME

Customized

Customized

After-sales Service

Yes

Steel Tolerance

+/- 0.01mm

Machining Tolerance

+/- 0.01mm

Machining Process

CNC, EDM, Drilling, Grinding, Wire Cutting

Heat Treatment

Yes for Hardened Steel

Nitride

Yes

Steel Type

P20, H13, S136, 420ss etc.

Unit

Metric or English

Mould Trial

Yes

First Article

Yes

Mould Trial Video

Available

CMM Inspection

Available

Electrodes

Copper or Graphite

Transport Package

Crate/Pallet

Specification

S136/420SS

Trademark

Win Win Mold

Origin

China

HS Code

8480719090

Production Capacity

500 Molds/ Year

Packaging & Delivery

Package Size

50.00cm * 40.00cm * 30.00cm

Package Gross Weight

120.000kg

Product Description

Product Description| 1 | Mould Base | LKM, DME, HASCO etc ; |

| 2 | Cavity Material | 1.2738,1.2343, 1.2344, S7, H13, P20, P20HH, GS738H, LKM738H, 718, 8407, S136, Calmax 635, NAK80, SKD-61,NIMAX, 45#, 50#, Aluminum for prototype mold etc. |

| 3 | Steel Hardness | HRC 20-60 |

| 4 | Treatment | Pre-Harden, Nitride, Heat treatment, Quenching |

| 5 | Cavity Qty | Single-cavity / Multi-cavity |

| 6 | Runner | Cold runner or Hot runner :YUDO/ HUSKY/ MOLD-MASTERS/ SYNVENTIVE/ INCOE/ MASTIP/ HASCO/ DME |

| 7 | Gate | Submarine gate, tunnel gate, side/edge gate, direct gate, pin point gate, sprue gate, diaphragm gate, fan gate, cashew gate, hook gate, hot tip, hot drop, valve gate etc. |

| 8 | Plastic material for parts | PS, SAN, PA, POM, ABS, PP, PET, PC, PE, HDPE, PA66+GF, NYLON 6/66, PPSU, PEEK, PVC, TPE, TPU, TPV etc |

| 9 | Mould Life | 50K - 1 million cycles |

| 10 | Design Software | UG, CAD, PRO-E, Solid Works etc, |

| 11 | Process | CNC, high speed carve, EDM ,wiring-cutting, drill, polish etc |

| 12 | Quality | ISO9001:2000 Certified |

| 13 | Lead Time | 10-30 work days depends on the structure and size of products |

| 14 | Package | Wooden Case Package or according to customer requirement |

| 15 | Price Term | EX Works, FOB Shenzhen, FOB Hong Kong, China, CFR, CIF, DDU, DDP |

| 16 | Payment | T/T, Western Union , Money Gram |

| 17 | 20 years professional manufacturing experience, specialized in design and manufacture of plastic injection mould ( tooling) for Automotive, Electrical appliances ,House wares , Medical devices, Toys and Games, Communication industries and etc. | |

| 18 | OEM & ODM orders are welcome. | |

Certifications

Company Profile

Welcome to Win Win Industrial (Shenzhen) Co., Limited! Established in 2006, Win Win Mold offers a wide range of services, including product design, prototype parts making, mold design, mold making, and molding production. Specializing in plastic injection mold designing for industries such as Automotive, Household appliances, Electronics, Medical, Packaging, Telecommunications, and Industrial tools.

Key Features:

Wide variety of Plastic Injection Molds

Multi-Cavities Molds

2-Shot / Multi-Material Molds

Over Mold

Unscrewing Molds

Insert Molds

Stack Molds

Cold Runner, 3-Plate, Semi-Hot, and Full Hot Runner Molds

Rapid Prototyping Molds

Large size molds

Gas Assist Molds

In Mold Labelling IML / In Mold Decoration IMD

Die Casting tools

Automotive Checking Fixture

Benefits of Choosing Win Win Mold:

Experienced enterprise with years of development

Turnkey services from design to production

High-quality molds for various industries

Specialization in plastic injection mold designing

Support from a dedicated team for project success

Plastic Injection Molding Production

On-site injection plastic mold repair & maintenance

Injection machines ranging from 80 - 600 tons

24-hour plastic molding manufacturing shifts

Long and short plastic injection molding production runs

Insert molding, dual-color molding service

General resin and industrial plastic such as ABS, PP, PE, HDPE, LDPE, PC, PC+ABS, POM, PA66+33%GF, PPT, PVC, etc.

Product Description

Win Win Industrial: Your Manufacturing Partner

At Win Win Industrial, we specialize in turning your product ideas into reality. Whether you have a new concept or existing CAD drawings, we provide technical evaluation, material selection guidance, and efficient manufacturing options.

Key Features:

Technical evaluation of product ideas

Material selection guidance

Quick reaction times to changes

Prototype models for design and functional evaluations

Expert advice on mould tool options

Weekly updates on mould building progress

Benefits:

Save time and money in production

Flexible manufacturing options for small or large quantities

Efficient delivery of T1 parts within 3-6 weeks

Transparent communication with weekly progress updates

Contact Win Win Industrial today to bring your product ideas to life!

Win Win Mold: Custom Plastic Injection Molding

Win Win Mold, a division of Win Win Industrial (Shenzhen) Co., Limited, offers full-service Plastic Injection Molding with experienced tool makers and setters to ensure optimal product output in minimal time. Your product is molded to your specifications and undergoes rigorous quality inspections for accuracy and quality.

Let the Win Win team support you in making your next project a success!

Our Advantages

Win Win Mold - Quality Molds for Quality Parts

At Win Win Industrial (Shenzhen) Co., Limited, we are committed to producing top-notch molds with innovative designs. Our expert engineering team utilizes advanced CAD/CAE/CAM systems to create molds that are not only easy to maintain but also cost-effective to manufacture.

Engineering Capability

Our engineers collaborate closely with customers to ensure the development of well-designed molds and plastic components. With a robust project management process, we deliver high-quality molds and products with fast lead times.

Win Win Mold - Quality Control

Quality Control

At Win Win Industrial (Shenzhen) Co., Limited, quality is our top priority. We implement stringent quality control measures throughout the process to meet the highest standards. Our QA team uses advanced manufacturing and inspection equipment to ensure precision and consistency in producing top-quality parts with minimal cycle time.

Key Quality Control Measures:

Mold Design Control

Mold Steel Hardness Inspection

Mold Electrodes Inspection

Mold Core and Cavity Steel Dimension Inspection

Mold Pre-Assembly Inspection

Mold Trial Report and Samples Inspection

Pre-Shipment Final Inspection

Export Product Package Inspection

Rely on Win Win Industrial (Shenzhen) Co., Limited to deliver quality molds that produce superior parts for your projects. Contact us today for all your mold design and manufacturing needs!

FAQ

Household Product Molding with Prototype Production

Welcome to Win Win Industrial (Shenzhen) Co., Limited Explore our Household Product Molding with Prototype Production services that provide precise plastic manufacturing and rapid tooling solutions.

Features:

Precision plastic manufacturing

Fast tooling solutions

Prototype production services

Benefits:

High-quality household products

Quick turnaround time

Cost-effective solutions

Product Description

Win Win Industrial Product Description

Welcome to Win Win Industrial At Win Win Industrial (Shenzhen) Co., Limited, we specialize in turning your product ideas into reality. Take a look at some of the common questions we often receive:

FAQ:

Win Win Industrial Product Description

Welcome to Win Win Industrial! Are you looking for a reliable partner to bring your product idea to life? Look no further! Win Win Industrial (Shenzhen) Co., Limited is here to help you every step of the way.

Key Features:

Expert evaluation of technical feasibility

Quick reaction times and overnight shipping

Utilization of CAD drawings for manufacturing

Creation of prototype models for testing

Recommendation of the best plastic material for your design

Advice on single or multi-cavity mould tools

Timely delivery of parts with regular updates

Benefits of Choosing Win Win Industrial:

Guidance on materials and manufacturing costs

Flexibility to accommodate demand shifts

Streamlined production process with various file formats

Design evaluations and market testing with prototype models

Expert recommendation on suitable materials

Customized advice on mould tool selection

Efficient delivery of parts within 3-6 weeks

Partner with Win Win Industrial today and turn your product idea into a reality!

Packaging & Shipping

>> Multifunction Toothpaste Tube Squeezer Squeezer Toothpaste Easy Portable Plastic Dispenser Bathroom accessories

>> Chinese Herbal Extract Cassia Polyphenols Ceylon Sticks Cortex Organic Cinnamon Powder

>> Tonva Milk Bottle Blow Molding Machine

>> High-Quality PVC Pipe Fitting Injection Molding Machine Price

>> Lab Equipment Electronic Optical Binocular Biological Microscope for Sale

>> Custom Transparent Light/Flow Quartz Glass Rod High Temperature Resistance High Light Transmittance

>> China Factory of Laptop Charger 72W 16V 4.5A for Lenovo IBM Adapter

>> front bumper (down) FOR ENCORE GX 2020-2021

>> Carbonized commercial food dumpling mini bamboo steamer

>> Amazon Wholesale Hot Sell Novelty Water Toy Cute Snail Interaction Toy Baby Plastic Summer Outdoor Beach Toy Children Kid Funny Squize Toy

>> High Accuracy 18 Inch Two Roll Rubber Sheeting Mixing Mill Machine

>> Hair Removal Customized Trio Waves 10bars 600W Vertical Portable Laser Diode Stack Module Parts for Apolomed

>> High Efficient Gold Mining Iron Zinc Silver Copper Ore Manganese Separating Froth Flotation Cell Tank Machine for Sale

>> Best Service 100 a AMP Plasma Cutter Cutting Machine

>> Custom FRP Vertical Chemical Storage Tank for Fuel

>> Automatic Corrugated Paperboard Vacuum Fingerless Single Facer Plant Machine

>> Double Glazed Thermal Break Aluminum Stainless Steel Horizontal Hanging Aluminum Alloy European Customized Size casement windows

>> China High Quality Ferro Silicon/Steel Making /Casting

>> 90% New Second Hand Excavator EPA CE Cat320d Heavy Duty Used Excavator Mini Excavator Crawler Excavator at Factory Price

>> Pm-3850A Plastic 5 Gallon 20 Liter Water Bottle Cap Making / Manufacturing Machine / Injection Molding Machine Price

>> 5A06 5356 5019 Aluminum Welding Wire Rod Aluminum Wire

>> Hdk 8-Seater 48V New Energy Mini Electric Vehicle Cars Golf Cart

>> Orchard Lift Farm Vehicle in AC Motor 2 Kw X 2 Hydraulic System Ecas-100h

>> Planetary 4 Heads Concrete Floor Grinder for Sale

>> Ma1420e/750 Heavy Duty Universal Cylindrical Grinding Machine Flat Surface Cutter Grinder 750 mm

>> Optix Rtn 905f Indoor Split IP Microwave Transmission Radio Idu Rtn905f

>> Hotel Double Wall Metal Electric Water Kettle with Tray Set

>> 1-20t/H Commercial Animal Poultry Cattle Feed Pellet Mill Equipment

>> Cheap mobile house door porte coulissante exterieure upvc bathroom plastic door PVC doors

>> A312 304/316/310S/321/321H /347H Seamless Stainless Steel Pipe