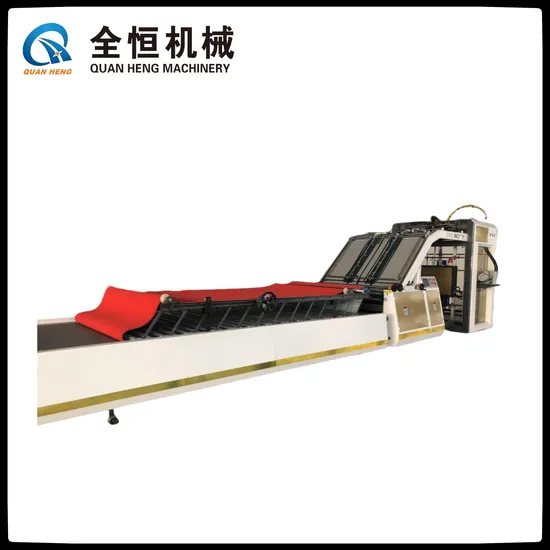

Full Automatic Flute Laminating Machine

Basic Info.

Model NO.

QH

Classification

Cold Laminating Machine

Application

Particle Board, Fiberboard, Plywood, Aluminium Plate, Packaging Paper, Film Material, Color Printing, Soft Board

Driven Type

Electric

Automatic Grade

Automatic

Membrane Material

Paper

Plastic Film Mulching Modes

Cold Laminating

Performance

Waterproof

Product Name

Cardboard Carton Automatic Laminator Machine

Glue Type

Cold

Model

1300/1450/1600

Speed

0-100PCS/Min

Trademark

QH-PACK

Origin

China

HS Code

84413090

Production Capacity

100/Pieces

Product Description

Automatic Laminator MachineProduct Description Introduction: Suitable for laminating of cardboard and corrugated cardboard in 150-600 g/m2 . The vacuum suction-type feeding system can lead the paper accurately into the machine;cycle stacking planes in a state of non-stop the next batch of paper stack well, so that more efficient. Using suction automatic feeding of bottom sheet, according to the main machine operating speed, continuous automatic tracking. The machine operation is stable, surface paper with corrugated paper joint very accurate. The corrugated paper never pull ahead, surface paper's location is easy adjust. Machine uses touch-screen/PLC/servo motor control system, double frequency control type , the circuit system is stable, and can automatically display the failure alarm. Automatic gluing, and the glue can be used circulatory, avoid glue waste. Measure roller line-speed design scientifically, avoid glue fly out when the speed is high. Pressure rollers adopt unilateral adjustment, convenient and fast. Cleaning type : bottom roller is extruded by rubber roller to clean the bottom laminating pressure roller, ensure the cleaner on the reverse of the bottom paper . Make glue etc. foreign matter after washing direct subside in tank. At the same time , adopting the gear and chain to control the lifting of tank, can take out the tank easily and convenient to wash . The pressure conveyor adopt floating movable structure , total length 5m , equipped with 28 paper pressing rollers , make the cardboard uniform bearing strength in pressing process. Counter designs scientifically, easy recording the amount you have been worked. Small pressure table (optional) . length 2.5m , big pressure table length 5m

| Model | BZJ-1300L | BZJ-1450L | BZJ-1600L |

| Maximum size | 1300×1100mm | 1450×1100mm | 1600×1100mm |

| Minimum size | 400×400mm | 400×400mm | 400×400mm |

| Appropriate paper | Top Sheet:200-450g Card(Bottom Sheet):350g ABCEF Flute | Top Sheet:200-450g Card(Bottom Sheet):350g ABCEF Flute | Top Sheet:200-450g Card(Bottom Sheet):350g ABCEF Flute |

| Max Speed | 6000Sheets/h | 6000Sheets/h | 6000Sheets/h |

| Total power | 13kw | 13kw | 13kw |

| Overall dimension | 12000×2250×2655mm | 12000×2400×2655mm | 12000×2550×2655mm |

Company Profile

Packaging & Shipping

FAQ Q:Are you manufacture or trading company? A:we are manufacture , our factory set up on 1999, and before we exported our products are mainly supply to the trading company ,so we are the source factory, welcome to be our agency. Q:Do you inspect the finished products? A:Yes, we have QC department, they will inspect the machine before shipping, to ensure there is nothing problem of the machine . Q:Does the packing strong? A:Yes, of course! All of our export packing with strong wooden tray, all to meet the export packaging standards. Q:How about after-sales service process? A:When your machine has problem, contact our sales and we will solve your problem as soon as possible.We have after-sale office in China, Vietnam, India, Bangladesh, Italy. Q.Where is your factory? A:Our factory located in Development Zone, East Of DongGuang County, CangZhou City, Hebei Province,China,welcome to visit our factory! Q. Do you have Import & export right? A:Yes , we have , so we can export the carton machines to you directly , without any trading company agency

>> Stainless Steel 304L 316L Round Hole Perforated Metal Mesh Sheet

>> China Factory LED Spotlight GU10 MR16 2835SMD 120° Spot Bulb Lamp 220-240V 3-7W for Indoor Commercial Spot Lighting

>> Glove Dipping Machine Glove Production Line/ PU Coating Gloves Machine

>> Postal Secure waterproof Outdoor Top opening Standalone Courier Parcel Delivery Box with anti theft lock

>> Self Service Car Wash Machine Price for Washing Car

>> SO 239 to SMA Male Adapter,UHF Female to SMA Male Plug Adapter

>> Body kit for TOYOTA HILUX VIGO 2005- 2018 Upgrade to ROCCO 2020 -2021 model

>> X6332Z High precision Vertical and Horizontal Drilling Milling Machine

>> Disposable medical sterilized cotton swabs automatic packing packaging machinery

>> Educational Wooden Toy School Children Interesting Pancake Maker Toy Game

>> Motorcycle Spare Parts Fuel Pump Bomba Combustivel Combustible Pop 110 I

>> Focus 25m3/H Lift Hopper Mini Concrete Batching Plant for Sale

>> Sustainable Fully Continuous Pyrolysis Plant System Turn Waste Tyre/Plastic Into Carbon Black

>> High Quality Colorful RGB LED Light Tube

>> Livestock Machinery Cattle Sheep Chicken Goose Mini Mixer Feeder

>> Electrophoretic Painting Equipment ED Coating Line Ced Painting Line for Auto Industry

>> China New Crop Fresh Winter Melon Supplier

>> Wholesale N52 Powerful Block Magnet 50X25X10mm Neodymium High Temperture Magnet

>> Made in Yincai, China, Waterproof and High-Looking Sports Equipment Water Transfer Decals

>> China Origin Multi-Function Pressure Fryer

>> Gsw-Sf Handheld Laser Light Welder with Auto Feeder System for Kitchen Ware

>> Digital Cutter Oscillating Knife EVA EPS Foam Sponge Rubber Cutting Machine for Corrugated Paper Showcase, Reflective Strips, MDF, Plastic

>> For benz W204 Front Bumper Side Skirt Exhaust Pipe W204 C63 Body Kit

>> TCA Potato Chips Grain Persimmon Fruit Onion Fish Cocoa Beans Mushroom Dryer Drying Machine

>> Cone Stainless Steel Mobile Transfer Silo Vertical Feeding Device Integrated Silo Metering Bin

>> Xhnotion 2MP-20 Brass Arduino Latching Bi-Stable 3V-12VDC Water 3/4 Solenoid Valve

>> 3D Industrial Machine Section Model Maker (JW-66)

>> Heavy duty outdoor telescopic hanging clothes rack

>> Foot Massager Mat with Roll Electric USB LCD Portable Rechargeable Massagers

>> China Supplier Xingfeng 42t Wheat Flour Mill Machine Milling Plant