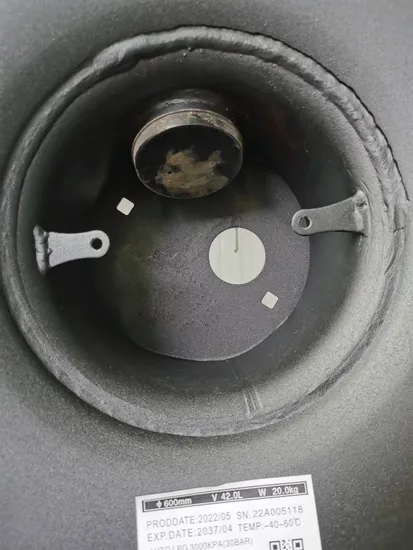

LPG Tire Cylinders 51L LPG Tire Bottle 580mm Wall Thickness Industrial Use 180mm Height

| US$20.00-100.00 | 100 Pieces (MOQ) |

Basic Info.

Function

Storage Pressure Vessel

Application

Gas

Material

37mn

Pressure

10.0MPa≤p<100.0MPa

Storage Medium

Oxygen

Pressure Level

High Pressure (10.0MPa≤p<100.0MPa)

Condition

New

Certificate

ISO9001

Color

Option

Transport Package

Nacked

Specification

6M3

Trademark

FM

Origin

Hangzhou

HS Code

7311009000

Production Capacity

500000 PCS Per Year

Product Description

The manufacturing process of LPG Tire cylindersThe material of the gas tank is steel with a thickness of about 2.5mm, and the gas tank is a kind of steel cylinder for storing gas. Because of the special use of the cylinder and the production process, the steel material is high strength steel and can meet its strength requirements.

The round sheet material is stamped out by the punch and die, and the material has been carefully calculated according to the size of the cylinder. "Gas tank" in the long-term filling, transportation, use of the process by collision, exposure, medium corrosion damage, will produce fatigue cracks, pits, deformation, corrosion and other defects, these defects are the direct cause of the explosion accident, if you encounter such a phenomenon, should be abandoned in time, after all, like this cylinder only a hundred blocks.

Preheat forming

The hardness of the material is strong, in order to reduce the internal stress of the material and reduce the yield strength of the material, it is necessary to heat the material, commonly known as hot flushing.

The hanger pulls out the preheated iron block and enters the next forming process.

The preheated material is placed on the lower die of the press by manual use of tools. The lower die has two pieces of positioning to prevent the material from being placed in the wrong position. After the material is placed, it is time to press the forming stage.

The press presses the material into bottle shape without any effort

After the first stamping is completed, the diameter of the cylinder is still relatively thick, and of course, it needs to be fine blanking, including surface smoothness, and to reach the standard size

The emulsion needs to be added during fine blanking. Benefits: 1. Cooling; 2. Prevent workpiece strain; 3. Lubrication, etc

The stamped base is prepared in advance and combined with the cylinder base by the press to ensure the quality of the bottom

The workpiece moves in a circle, the equipment at the opening continues to heat, and the spinning machine moves regularly.

| NO. | liner diameter | working pressure | thickness | length | weight | quantity(pc) |

| 40L | 580mm | 200bar | 4.8mm | 200mm | 19.6kg | 100 |

>> Metal Cut Bending Horizontal V Groove Machine for Metal Grooving

>> Winter Snow Suit Warm Windproof 10000mm Waterproof Outdoor Sports Ski Snowboarding Jacket

>> Sf-113 Easy Installation Foot Pads /Plastic Bottom Pads for Furniture

>> China Supplier DIN934 High Strength SS304 SS316 Stainless Steel Hex Nut

>> Module spare parts TRIPLEX 9802

>> Cartoon Transparent Student Stationery Ring Zipper Pen Bag Large Capacity Bag

>> Cheap Price Square 10 Inch 1024*600 Thinnest LCD Digital Photo Frame RoHS with Picture Video Loop Playback

>> Good Quality Plastic Products Inject/Injection Mould/Moulding Machine 700ton

>> Cooray Crl200tl Turning Parts Center CNC Turning Lathe Mazak Design

>> High Purity Boric Acid 50 Kg for Corn

>> HC-S420 Denta lteeth model with teeth root human standard removable teeth model for study

>> HRA-II Medical Body Checking Machine Full Body Check Up Diagnosis Test Equipment Health Screening Machine

>> Aluminum Composite Panel ACP Reflective Traffic Signs for Road Safety Warning Sign

>> High Speed Single Pass Roll Paper Digital Printing Machine

>> Taiwan Dawei Professional Compact CNC Gantry Machine Center Gmc3027

>> FS1251,33472,P550248 Fuel Filter for Cummin s Engine

>> Front Left Fender 1z0821105A for Skoda Octavia A5

>> Fluorocarbon fishing line 100m JapanYGK OLLTOLOS N270 100M Fluorocarbon line strong strength

>> Durable Metal Lathe Tl4211-Tl4216 Metal Bench Lathe Turning Center

>> Auto Fan Motor Cross Number: 38616-Rlf-901 for Honda Radiator Fan Motor Hight Quality

>> Cheap China Reliable Plastic Fruit Crate Bucket Chair Pipe Hanger Spoon Fork Knife Making Injection Molding Moulding Machine Price

>> Hot Selling China High-Quality Phosphoric Acid 85% for Food Grade High-Quality Supply Factory Price Phosphoric Acid

>> Fully Automatic Bottle Blowing Machine for 5L Pet Bottles

>> ISO 1133-1 Melt-blown Nonwoven Fabric Melt Flow Index Testing Machine

>> 2021 Xiaomi Wireless Power Bank 10000 Qi Power Bank 10W 10000mAh Portable Charger WPB15PDZM USB C

>> Hot selling wrist wrap support men weight lifting gloves fitness gym gloves

>> Magnetic Control Dynamic Bicycle Home Room Quiet Bicycle Sports Weight Loss Fitness Equipment

>> Driveway Marking Tempered Cat Eye Reflective Glass Road Stud

>> New Crop High Quality Fresh Yellow Onion Mesh Bag with Good Price

>> 21 DAIWA DE-5600CS Mens Wholesale Fishing Clothing UPF50 Sun Protection Long Sleeve Fishing Hoodie