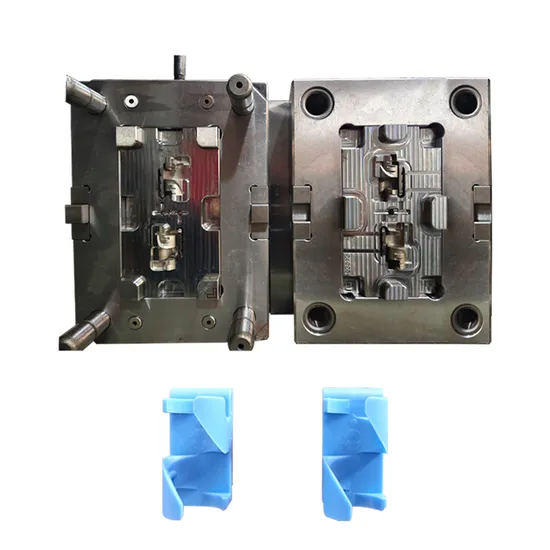

Custom Medical Parts Mould Precision Medical Plastic Mould

| US$1,000.00-20,000.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

24025

Surface Finish Process

Polishing

Mould Cavity

Multi Cavity

Plastic Material

PP-5090t

Process Combination Type

Progressive Die

Application

Medical

Runner

Cold Runner

Design Software

UG

Installation

Fixed

Certification

TS16949, ISO

Standard

PUNCH

Customized

Customized

After-sales Service

10 Years

Mould Life

0.5-1 Million Shots

Mould Material

P20/718/2344/Nak80/S136/2738/2316

Cavities Number

1*2

Cycle Time

25s

T0

30days

Dimension Tolerance

Within 0.02mm

Transport Package

Wood Case

Specification

230*250*251mm

Trademark

Can be customized

Origin

Xiamen, China

HS Code

8480790090

Production Capacity

300sets/Year

Packaging & Delivery

Package Size

28.00cm * 30.00cm * 30.00cm

Package Gross Weight

106.000kg

Product Description

Product Description| Place of Origin: | Xiamen,China | Application: | Medical Device |

| Cavities Number: | 1*2 | Shaping Mode: | Plastic Injection Mould |

| Cycle Time: | 25s | Mould material: | P20/718/2344/Nak80/S136/2738/2316 |

| Injection Material: | PP-5090T | Mould Life: | 0.5-1 Million Shots |

| Mold base: | KM.HASCO. DME or Chinese standard | Tolerance: | ±0.02mm |

| Drawing Format: | STEP/STP/IGS/X-T/STL/CAD/PDF/DWG and Other | Warranty: | 1year |

| Runner: | Cold Runner | Certification: | ISO13485 |

Detailed Photos

Company Profile

What's we can make for you?

XIAMEN XIN HAI SHENG PLASTIC CO.,LTD is a "one-stop-shop" injection mould factory for all your mold & molding needs.As a molding maker, we have been in mold & molding industry for more than 10 years in China. We specialize in custom mould & moulding service 100% made in china from product design to final part production.

We manufacture plastic molds & molding,We currently have a wide range of moulding equipment.We can customize injection mould include auto parts, medical component part,electronic accessories, household appliances, daily necessities and children toys and other customize plastic products.with our knowledge, we can provide outstanding service to meet all your mould part requirements. Our facility and technical capability will exceed your expectations on service, quality and value.

Are you a crowd funding project leader or a great ideal inventor or an industrial product designer or a production factory manager or a project manager or a new parts business investor?If you are looking for a injection mould company with profound experience and high quality products, we will be your good working partner in china who makes your dreams come true.

Injection Mould samples

Injection Products Samples

Our Advantages

Core Advantage of XinHaiSheng

1) High quality with cost-saving design

Our engineers with over 10 years' experience would design the plastic injection molds with the most reasonable design.

2) Commitment to Quality & Competitive Price

With diversity in equipment capabilities and in-depth knowledge about industrial injection mold, Xin Hai Sheng is able to offer Competitive Price for all products and services reasonably.

3) Delivery on time within budget

We help customers control costs, create and execute the most efficient schedule for each project, taking full advantage of our supply chain network and mold processing and injection molding capabilities.

4) High quality service

At Xin Hai Sheng, the fast-response service is just the basic requirement, professional and efficient are our strength!

5) One-stop service provider

Technical support from the initial product design to the entire stage of mold making and product production and delivery.

Certifications

Packaging & Shipping

After Sales Service

We Can Offer You:

1.Good steel with high hardness

2.Good accessories with high brightness

3.Good machining with high precise

4.In-time response on email, telephone calls or fax

5.In-time supply the quotation and mould designs

6.In-time communication on the technical points

7.In-time sending pictures for the mould machining progress and mould finishing schedule

8.In-time mould test and sample delivery

9.In-time mould delivery

Sale Services

Pre-sale service:

Our company provide good salesman for professional and promptly communication.

In-sale service:

We have strong designer teams, will support customer R&D. If the customer send us samples, we can make product 3D mapping, modeling and drawing, then do the modification as per customer request and send to customer for approval. Also we will provide customers our technological suggestions according to our experience and knowledge.

After-sale service:

We will provide some spare parts for the easy-to-break parts, you can replace when you need. If our product have quality problem during our guarantee period, we will give you the best solution at the fastest speed, and send you free for replace the broken piece; also if you have any issue in using our moulds, we will provide you professional communication.

Other Services

We make the commitment of service as below:

1.Lead time: 30-50 working days

2.Design period: 1-5 working days

3.Email reply: within 24 hours

4.Quotation: within 2 working days

5.Customer complaints: reply within 12 hours

6.Phone call service: 24H/7D/365D

7.Spare parts: 30%, 50%, 100%, according to specific requirement

8.Free sample: according to specific requirement

FAQ

Q1: Are you trading company or manufacturer?

A1: We are direct factory for mould making with more than 10 years experience.

Q2: Where is your factory located? How can i visit there?

A2: Our factory is located in Tong'an District, Xiamen City, China. 20 minutes by car from Xiamen International Airport , 15 minutes from train station to our factory.We can pick you up if you need,welcome to visit our factory.

Q3: What do we need for mould quotation?

A3: We usually need the following information,

(1) Mould steel raw material you need or mould life you need.

(2) Mould cavity No. you want?

(3) 2D or 3D product drawing, or pictures with detail sizes information (length, width, height, thickness), or send samples directly to us.

(4) Raw material of the product.

(5) Hot runner or cold runner, if hot runner which brand of hot runner you require.

Q4:How long does it take to make a mould?

A4:The production time depends on your specific requirements, normally the lead time is 10-60 days.

Q5:Do you offer secondary services such as assembly, packing or painting?

A5:Yes, such as assembly, painting, tapping, ultrasonic welding, trimming, sorting, custom packaging and etc.

Q6:If I have existing tooling, can you use it to mould my project?

A6: Absolutely, if you have existing tooling we can use it.

Q7: How about quality control in your factory?

A7: We believe that "quality comes before everything". We mainly carry out the following procedures:

(1) Design optimisation inspection

(2) mould steel hardness inspection

(3) mould assembly inspection

(4) Mould trial sample inspection.

(5) Final mould & packaging inspection before shipment

Please send us 3D/2D drawings or samples if you have any queries regarding the above.

>> W11S-12X4000 Hydraulic upper roller universal plate bending rolling machine

>> Admixture Concrete Aluminium Powder Paste for Lightweight Concrete

>> TRICONEX AI2351 SIS safety system industrial control spare parts module

>> Medical Disposable Equipment Intravenous Infusion Set

>> Enclosed Whiteboard Magnet Planner Chalkboard Calendar for Fridge

>> Cr or Galvanized Fha Strap 16ga

>> Compact Electric Bench Drill Press

>> polyester cotton fiber opening pillow filling machine wool opener cotton waste fiber opener recycling machine

>> Advanced Design Bottle Filling Capping Machine for Liquid Makeup Foundation

>> motorcycle / motorbike / scooter tyre nozzle repair accessory VAMD161 TR161 air tire valve

>> Windshield Glass Crusher / Automotive Glass Crusher / Laminated Glass Recycling Machine

>> New design high quality best item Export Quality hot sale Men's Hoodies

>> Terminal Block Adapter Electronics Stick Accessories USB Data Cable Wall Socket for USB Stick

>> Wholesale Men Luxury Customized Active Clothes Men Water-Proof Puff Down Parka Coat Male Down Jackets Outdoor Outwear Man Wind-Proof Outdoor Coat Fur Hood

>> Vertical Plastic Cutting Machine Cutter

>> Custom-Made Plastic Injection Tooling for Portable Charger Components

>> Digital Display Controller Automatic Glass Sliding Door Operator/Kit Ce & RoHS Certification

>> Split AC Air Flow Deflector Anti-Directly Blowing Retractable AC Windshield Universal Free Installation

>> China Custom Self Drilling Screws Tapping Screws Wood Screws Machine Screws Cap Screws Set Screws Flat Head Screw Furniture Screws Non-Standard Screws Fasteners

>> High-Quality Hollow Prefabricated Board Machine

>> Diesel engine driven corn straw grinding machine hammer milling machine

>> Horizontal GF2300 Injection Molding Machines for Making Chair Trash Bin

>> Markdown Sale New Olive Tree Shaker Harvest Machine

>> Artificial Floor-Type Sumore Made in Shanghai China Horizontal Machine Metal Lathe

>> Automatic Dough Divider Rounder Machine

>> Automatic Precision Surface Milling Grinder

>> Factory Price Automatic Continuous 1000W 1500W 2000W Handheld Fiber Laser Welding Machine for Lithium Battery Pack

>> Gn125 Front Motorcycle Suspension Assy Front Fork Pipe Shock Absorber Spare Parts OEM Supplier China Hot Sale Model

>> Haide Apm Corn Sheller Thresher Machine China Manufacturing Apm500 Multi-Function Farm Use Fresh Sweet Maize Thresher

>> Wind Cooling Hot Cutting HDPE LDPE PP Plastic Recycling Machine