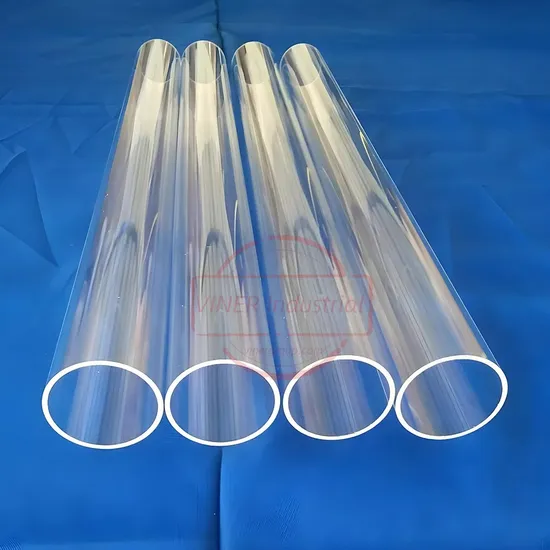

High Temperature Resistance Fused Silica Glass Quartz Furnace Tube

| US$1.28-6.88 | 1 Piece (MOQ) |

Basic Info.

Model NO.

VN-QT-T04

Type

Quartz Tube

Length

Max. 4500mm

Od

3-600mm

Thickness

0.3-20mm

Purity

99.99% Quartz

Density

2.2g/cm3

Transport Package

in Carton or Wooden Case

Specification

OD: 3-600mm Thickness Wall: 0.7-10mm

Trademark

VINER Industrial

Origin

Henan, China

HS Code

85149090

Production Capacity

10000PCS/Month

Product Description

High Temperature Resistance Fused Silica Glass Quartz Furnace Tube Product DescriptionVINER Industrial High Temperature Resistance Fused Silica Glass Quartz Furnace Tube has advantages of high purity, good spectral transmission, well controlled dimension and low OH, etc. 1200C High Temperature Resistance Fused Silica Glass Quartz Furnace Tube is the best heat resisting material for lamps like: halogen lamps, metal halide lamps, etc. We can produce the tubes within a very large diameter rang: OD3-600mm, thickness wall 0.7-10mm, length maximum3000mm. We also can apply some further processing like end closing trim cutting, fire polishing, sand blasting, bending, pinching, grinding and others according to customers' requirements. We also can control our tubes OH content within 20ppm\15ppm\10ppm\5ppm\2ppm as your special needs.

Product Features

1200C High Temperature Resistance Fused Silica Glass Quartz Furnace Tube Features:

These tubes advantages are high purity, good spectral transmission, well controlled dimension and low OH, etc. They're the best heat resisting material for lamps like: halogen lamps, metal halide lamps, etc. We can produce the tubes within a very large diameter rang: OD 3-600mm, thickness wall 0.7 - 10.0mm, length maximum 3000mm. We also can apply some further processing like trim cutting, fire polishing, bending, pinching, grinding and others according to customers' requirements. We also can control our tubes OH content within 20ppm\ 15ppm\10ppm\5ppm\2ppm as your special needs. High Temperature Resistance Fused Silica Glass Quartz Furnace Tube Advantage:

1. High temperature resistant: 1100 degree.

2. Corrosion-resistant

3. Good thermal stability

4. Good transparency for light

5. Good electrical insulation

Product Parameters

Parameter of High Temperature Resistance Fused Silica Glass Quartz Furnace Tube:

| Outer Diameter | 1.50-600mm |

| Material | high purity >99.99%(SiO2) |

| Wall Thickness | 0.30-20mm |

| Length | 10-4500mm |

| Shape | Straight, C, U,Round,Pear,spiral,domed, closed |

| Softening Point | 1680ºC |

| Annealing Point | 1210ºC |

| Strain Point | 1120ºC |

| Density | 2.2g/cm3 |

| Hardness | 5.5-6.50Mohs' |

| Design Tensile Strength | 4.80x 107 N/m^2 |

| Design Compressive Strength | 1.10x 109 N/m^2 |

| Cofficient Of Thermal Expansion(20-320ºC) | 5.70x 10-7cm/cm.ºC |

| Thermal Conductivity(20ºC) | 1.40W/m.ºC |

| Specific Heat(20ºC) | 670J/Kg.ºC |

| Electrical Resistivity(350ºC) | 7x 107ohm.cm |

| Dielectric Constant | 3.75 |

| Dielectric Strength | 5x107V/m |

1200C High Temperature Resistance Fused Silica Glass Quartz Furnace Tube Chemical Composition:

| Chemical Composition | ||||||||||

| AL | K | Na | Li | Ca | Mg | Cu | Mn | Pb | B | Ti |

| 20 | 3.5 | 3.5 | 1.0 | 2.0 | 0.5 | 0.3 | 0.5 | <0.01 | <0.2 | 2.0 |

1200C High Temperature Resistance Fused Silica Glass Quartz Furnace Tube Tolerance:

| Range of OD | OD | WT | Siding | Out of Round | Bow/1220mm |

| ≤6mm | ±2.0% | ±10% | 12% | 2.00% | 2.5mm |

| 6.00mm-15.00mm | ±1.25% | ±8% | 10% | 1.50% | 2.5mm |

| 15.00mm-20.00mm | ±1.25% | ±10% | 15% | 1.50% | 2.5mm |

| 20.00mm-25.00mm | ±1.25% | ±10% | 15% | 1.50% | 3.0mm |

| 25.00mm-30.00mm | ±1.35% | ±12% | 15% | 1.50% | 3.0mm |

| 30.00mm-80.00mm | ±1.5% | ±14% | 15% | 2.00% | 3.0mm |

1200C High Temperature Resistance Fused Silica Glass Quartz Furnace Tube Application:

This high temperature quartz tube is mainly used in electric light source, electrical appliances (electric), semiconductor, optical communications, military industry, metallurgy, building materials, chemical, machinery, electricity, environmental protection and other fields. Product Manufacture

Packaging & Shipping

VINER Industrial 1200C High Temperature Resistance Fused Silica Glass Quartz Furnace Tube Package:

1. Plastic Air Cushion Film

2. Foam Material

3. Paper Carton

4. Wooden Case

VINER Industrial 1200C High Temperature Resistance Fused Silica Glass Quartz Furnace Tube Shipping:

VINER Industrial can supply you the follow shipping way for your choice:

--By DHL/Fedex (Door to door, Home delivery service)

--By Air to your nearest Airport

--By Sea to your nearest Seaport

--By the sellers' shipping agent

Company Profile

VINER Industrial specializes in different sizes and kinds of quartz tubes, such as thick wall quartz tubes, large diameter quartz tube, quartz twin tube, u-shape tube, C shape tube, quartz capillary tube, perforated tube, four holes tube, one end closed tube, quartz test tube, heat resisting quartz tube, corrosion resisting quartz tube, and other special shaped tubes according to customers' design.

Welcome to visit manufacture line!! Wait for your testing our Quartz Tube products!!

Professional Quartz Tube Manufacturer: We have being specialized in producing quartz tube products for more than 10 years, and all our products are exported.

Guaranteed Quality: Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production.

Sound after Sales Service: We provide sound after sales service. We provide 24 hours' consultation service. We are ready to answer your consultations at any time.

What is more, VINER Industrial produces and supplies high temperature electric furnace and Kiln Furnace Spare Parts including MoSi2/SiC heating elements, Ceramic Fiber Insulation, Alumina/Zirconia Ceramics, SiC Ceramics, Vacuum Flanges, Thermocouple, PID Temperature Controller, etc. Ps kindly inquiry us, we will try our best to serve you.

Prompt reply within 24 hours without delay by our specialized after-sale service sector. Provide high temperature solutions and professionals construction services for different fields for our customers. Provide the most reasonable logistics for customers to save every penny. Production of goods are finished, thoughtful provide products and packaging photos for our customers. FAQ

Q1. Can you accept OEM?

Yes! We can manufacture as per your request size.

Q2. Are you a factory or trading company?

A: Yes, we are a factory & Trading Company, and have more than 10 production lines.

Q3. Can you deliver the goods use our shipping forwarder?

Yes, we can help you make the delivery using your forwarder.

Q4. What is your Min. order quantity?

No request of the MQQ, 1pcs will be OK.

Q4. Can you supply sample?

Yes, we can give you sample as per your request.

Q5. What about your After-sales service:

We promise that we can change or refund products if there are any quality problem.

>> 4yz-4sh Agricultural Machinery Self-Propelled Corn Harvester with 160HP 4rows Farm Machine.

>> High End Luxury Modern Design Wooden Executive Office High Office Cabinet B-Rt21-40 Large Office Filling Storage with Factory Price for Project and Wholesale

>> Full Level Plastic Raw Material Wankai Wk 801 Virgin Pet Resin

>> Stainless Steel Bicycle Lock with Key

>> Advanced 5-in-1 Hybrid CCTV Recorder for Diverse Cameras

>> 360 LED Tube Light for Night Club Decoration Rbg 3D DMX Digital D LED Color Light Tubes Meteor Lighting DMX512 360 LED Tube 30mm

>> Sticky Mat Peel off Clean

>> 216EA62 1MRB150083R1/F ABB module supply

>> Portable Type-C USB Direct Charge Rechargeable Camping Headlamp COB LED Light

>> Home Use Pipe Gas Booster Pump

>> Double Shaft Waste Tire Metal Scrap Drums Pipe and Plastic Shredder for Recycling Machine

>> Cw61180h/1-Swing Over Bed 1800mm-3m 15tons Workpiece Loads Heavy Duty Horizontal Lathe Large Size Lathe Torno

>> Permanent Stainless Steel Cathode Plate /Titanium Plate for Copper Electrorefining

>> Professional Powerful Safe 250A 8m Cable Hot Start Inductivity MIG MAG MMA TIG FCAW Welder IGBT Inverter Combo Welding Machine IGBT Welder

>> 1.8 Liter SUS304 Stainless Steel Cordless Electric Water Cooling Kettle

>> Grade80 Safety Lifting Sling Pivot and Swivel Hoist Ring

>> Automatic Waste Paper Blanking Separator Stripping Machine for Cigarette Box Cloth Label Tag

>> 2.5t/3t/4t/5t/5000kg Hairline Stainless Steel Auto Cargo Car Goods Elevator Lift

>> Huayu Plastic Tray Blow Moulding Machine

>> Australian standard double glazing waterproof aluminum awning window for bathroom windows

>> 1 Inch Water Filter Irrigation Kinetic Air Release Valve

>> China Cheap Heavy Duty Vertical Knee Type Milling Machine X5032 Price

>> All weather glass windows and doors thermal break aluminum casement window with double tempered glass

>> Portable Small LPG Cylinder with Camping Burner

>> New Rich Wholesale Tactical Suit Battle G2/G3 Suit Training Clothing Combat Acu/Bdu Multicam Tactical Uniform

>> High Quality Morden Doors Aluminum Glass Aluminum Casement Doorfor Office

>> Bison Small Portable Towable Portable Electric Mini Cement Concrete Mixer Machine

>> Professional Horizontal CNC Lathe for Turning 3000 mm Diameter Flange, Mold, Wheel

>> Waste Tire Recycling Line /Tire Cutter Machine /Tire Shredder Machine

>> Hot Stainless Alloy Steel Round Aluminum Flat Puff Angle Square Grab Towel Grade SUS Ss 304 316 409 Factory Price AISI Bar