Vh-25 CNC Milling Machine Machining Center with 7/7 Sec Tool Change Time

| US$54,000.00-55,500.00 | 1 Piece (MOQ) |

Basic Info.

Model NO.

VH-25

Type

Tool Milling Machine

Object

Tool

Structure

Bed type

Milling Cutter Type

Vertical Milling Cutter

Milling Cutter Structure

Integral

Controlling Mode

CNC

Automatic Grade

Automatic

Precision

High Precision

Certification

ISO 9001

Condition

New

Transport Package

Wooden Case

Specification

3230x3130x3200

Origin

China

Product Description

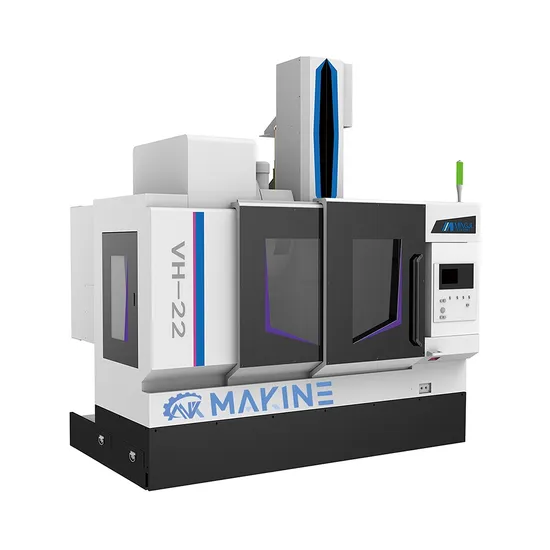

MINGJU CNC Milling Machine Machining Center VH-25Technical specification

| Item | Specification | Unit | VH-25 |

| Travel | X/Y/Z Axis | mm | 1500/650/600 |

| Distance from Spindle Front to Table | mm | 150-750 | |

| Guide Way Type | / | Three-axis Roller Linear Guide | |

| Table | Worktable Size L*W | mm | 1530*600 |

| Max. Worktable Load | kg | 2000 | |

| T-Slot (number of slots x size x distance) | mm | 5-18-125 | |

| Spindle | Spindle taper holes and specifications | Type | BBT50/HSKA100 |

| Spindle Speed | rpm | 8K | |

| Spindle Motor | kw | 15-18.5 | |

| Spindle Drive Type | / | Direct Drive/Gear | |

| Feed | X/Y/Z Axis Rapid Feed | m/min | 30/30/30 |

| Cutting Feed Speed | mm/min | 1-10000 | |

| Tool Change Device | Tool Magazine Form | / | Arm-type tool magazine |

| Tool Holder Specification | type | BBT50/HSKA100 | |

| Tool Capacity | tools | 24 | |

| Max Tool Diameter (adjacent tools) | mm | Φ105/Φ105 | |

| Max Tool Diameter (no adjacent tools) | mm | Φ200/Φ200 | |

| Maximum Tool Length | mm | 350/350 | |

| Maximum Tool Weight | kg | 15/15 | |

| Tool Change Time | sec | 7/7 | |

| Accuracy | Positioning Accuracy | mm | ±0.003/±0.005 |

| Repeat Accuracy | mm | ±0.003 | |

| Power Requirements | Power Requirement | kVA | 45 |

| Air Pressure Requirement | kg/cm² | 6~8 | |

| Machine Dimensions | Length/Width/Height (Including Water Tank) | mm | 3600*3200*3750 |

| Weight (Including Water Tank) | ton | 11 |

Product Description

High Rigid Structure, Eccellent Manufacturing

Mingju VH series adopt T-shaped structure bed, full support for X-axis table, transverse movement along the bed, Y-axis is bullhead type supporting back and forth movement, with perfect support and structural rigidity. The foundation parts are all made of high-quality grey cast iron with resin sand casting process, and the reasonable arrangement of the fascia plate is carried out according to the kinetic analysis, which ensures that it has a good resistance to twisting and bending ability. The three linear co-ordinates adopt imported heavy-duty linear roller guide sub, with large load capacity and strong anti-twisting ability. The ball screw adopts pre-drawn high-precision screw with fixed support at both ends of the screw. The center bearing of the rotary table adopts precision grade rolling bearings and is strictly preloaded to increase the rigidity of the feeding system.

High Precision

The high rigidity of the machine's basic parts provides a guarantee for the machine's good precision stability. At the same time, the machine has three linear coordinates and two rotary coordinates - (optional imported high-precision optical scale), so that the positioning and repeat positioning accuracy of the machine can be further improved; Cooling nozzles at the front of the spindle and the high-pressure spray nozzle at the top of the fully enclosed shroud provide all-around coolant for the machined the processed workpiece, preventing thermal deformation and ensuring high accuracy. High Torque, Heavy Cutting Spindle Structure

The spindle box adopts high rigidity square ram structure, high-speed direct junction spindle assembly, spindle transmission force constant power range, spindle optional maximum power of 22KW, can be matched with secondary gear transmission output torque up to 1500NM. The spindle and spindle box are controlled by oil cooler with thermostatic cycle, which ensures stable working precision. VH20 can optionally choose high-speed spindle or high rigidity BBT50 spindle, while VH22, VH25 standard equipped with φ190mm high rigidity BT50 spindle. Fast and Reliable Automatic Tool Change (ATC)

Adopting ATC disc type tool changer mechanism, smooth tool change, high gripping force The tool magazine can hold 24-32 tools. The tool magazine is mounted by shoulder type, one-piece casting, good rigidity and strong stability.

Easy to Clean, Easy to Remove Chips, Easy to Maintain

The working area of the machine is centralized, with integral protection and concise structure. The water flushing chip removal on both sides of the working table or optional two automatic spiral chip removers can completely enable automatic chip removal. The inner side adopts stainless steel side plate, which is not easy to hang chips.

Process & Application

VH Series is suitable for the manufacturing small and medium batches of box-type parts, specifically stainless steel, steel parts, castings, alloys and other materials. With superior performance, all five faces of workpiece can automatically complete a number of side milling, boring, reaming and tapping and other processes within one clamp, which can save a lot of process equipment, and improve production efficiency. On the basis of the standard machine, 4th axis and 5th axis can be added on top with fixture to achieve multi-face manufacturing capability.

Company Profile

>> Digital Automatic Four-point Method Wenner Method Grounding Soil Resistivity and Earth Resistance Tester

>> Starch Powder Processing Horizontal Paddle Agitation Mixer

>> CNC Heavy Industry Boiler Tube Sheet Fabrication Steel Plate High Speed Hole Drilling Machine

>> front bumper lower FOR BUICK ENVISION S 2020-2021

>> Tisco Steel Supplier Gi Coil Z180 0.18mm 0.24mm 0.23mm Galvanized Steel Roll

>> Ultra Compact Industrial Motherboard J4125 Quad-Core/16GB DDR4 Dual LAN + Msata Storage 120mm Mini Industrial Computer

>> Cheap Price Metal-Forming CNC Tools 0.01~0.02 (mm) Vertical Milling Gantry Machining Center Machine

>> High Temperature Resistance Fused Silica Glass Quartz Furnace Tube

>> Factory Supply for Stadium Projector Lighting 10W 20W 30W 50W 100W 200W 300W IP67 IP68 LED Flood Light

>> SINOBI Gentlemen Business Stylish Handwatch Male Minimalist Watchs 3ATM Waterproof Wristwatches Men S9601G-D

>> Control Valve Fuel Metering Valve 0928400617 for Man Citroen

>> Plastic Engine Fans for Large Diameter Drilling Machine

>> Manual Metal Precision Flat Table Moving Surface Grinding Machine

>> Circular Saw Blade Machine Gear Grinding Machine CNC Automatic Sharpening Machine

>> Automation Chinese and English Bilingual Interface Settings Electric Servo Tapping Machine

>> Plywood Making Machine Knife Grinding Machine/Sharpener

>> Outdoor LED Blinder 18W Rgbaw LED Wall Washer for Stage

>> 106K 350V, Audio Capacitor, MPa Cbb20 Metallized Polypropylene Film Capacitor

>> Kobelco Secondhand Used Hitachi Big Cheap Digger Manufacturers Zx60c-6A Supplier Large Crawler Small Excavator

>> 4 Inch RGB Light Portable Bt5.0 Speaker Mini Wireless Bluetooth Bass Outdoor Speaker Battery Stereo Karaoke

>> High Quality Manual Compactor Factory Price

>> Wholesale Auto Car Spare Parts For B207 Z20NET Engine Timing Chain Kit TK1011-1

>> High Quality 99% Allyl Heptanoate CAS 142-19-8 with Accept Sample Order

>> Eco Diesel Heavy-Duty Hydraulic Agri Engineering Crawler Dumper Truck Conveyor Transporter

>> Ws-15plus CE Approved Mini Excavator 1ton Chinese Supplied Hot Sale New Design Digger Hydraulic Mini Excavator

>> Ce Approved Automatic High Speed Paper Bowl Machine (RD-12/22-100B)

>> Food Grade Citric Acid Monohydrate Anhydrous Sodium Citrate

>> Frp 4040 4inch Housing Ro Pressure Vessel Ro Water Treatment System

>> Efficient Paddle Mixer with Low Heat Generation for Temperature Sensitive Materials

>> Agricultural Irrigation Diesel Self-Priming Water Pump